Using QR Code Management to Reduce Instrument Information Query Time

Original: https://cli.im/article/detail/1823

We are the Instrument Management QC Group of the Adjustment and Testing Research Institute, Electric Power Research Institute, State Grid Liaoning Electric Power Co., Ltd. Last year, our project titled "Using QR Code Management to Reduce Instrument Information Query Time" won the second prize in the 2021 Shenyang Quality Science and Technology Achievement Awards. Invited by CaoLiao, we would like to share our experience with you.

Selecting the Topic

1. Needs Analysis

Instrument management is a crucial part of ensuring the timely, high-quality, and quantity-compliant completion of every project in the thermal power commissioning industry. It also serves as the foundation before the commencement of each project. The degree of instrument allocation and maintenance directly determines project quality and timelines. Instruments required in the thermal power commissioning industry mainly cover six major specialties: turbine, boiler, electrical, thermal control, chemical, and civil engineering. Instruments are often allocated to various projects based on their usage value, which necessitates comprehensive inventory registration before instruments are dispatched to each project. Additionally, information such as Chinese and English user manuals, calibration reports, operation videos, drivers, and after-sales contact details must be provided for each instrument to facilitate smooth usage by subsequent users. The combined number of instruments required by various specialties is not only large but also prone to statistical omissions, requiring instrument administrators to repeatedly verify outbound information. Similarly, when instruments are returned collectively or individually, the repetitive work must be done again, resulting in significant resource waste.

Our team conducted a highly randomized survey with the following content: "Randomly find the manuals for two different instruments in various engineering projects, using any method available, but the result must be successful, and accurately record the time from the start to the end of the search." This task considered that instrument manuals are the most basic and essential materials. The time from when a manual is missing and cannot be used normally to when the information is found can be equated to downtime. The test results completely exceeded our team's expectations. Some engineering projects could not proceed with the first step after participating in the survey. Specific results are shown in Table 1.

From the table above, it can be intuitively seen that the shortest query time was 13 minutes, and the longest was close to 20 hours. Moreover, most survey participants contacted the warehouse keeper to request after-sales contact information before reaching out to the manufacturer. Here, the team set two boundaries: 1 hour and 5 hours. Assuming that queries completed within 1 hour are considered passing, those taking between 1 hour and 5 hours are considered half-day downtime, and those exceeding 5 hours are considered full-day downtime. The test results are shown in Figure 1. It is evident that the results are not optimistic. If finding a manual is this challenging, domestic and international engineering personnel will encounter even more obstacles when searching for other information.

2. Defining the Needs

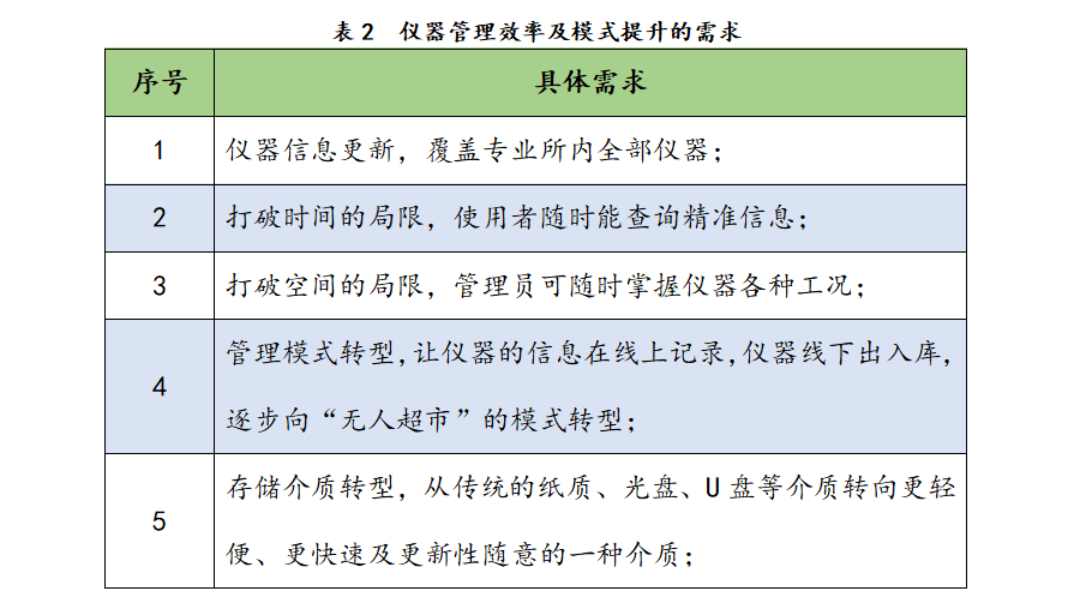

The Adjustment and Testing Research Institute handles the outbound and inbound logistics of instruments, spare parts, tools, and consumables daily. Supporting facilities such as Chinese and English user manuals, calibration reports, drivers, and various accessories must accompany the instruments to various projects, causing difficulties for users in terms of storage or loss. Often, due to material updates or instrument upgrades, administrators need to distribute new materials to various projects, which is particularly challenging for overseas projects.

Borrowing and returning instruments require registration, approval, and other procedures, which consume work hours. Sometimes, to save time, instruments are put into use without completing outbound/inbound and approval procedures, leading to inconsistencies between warehouse records and physical inventory, making it difficult to hold relevant personnel accountable. Moreover, when the instrument administrator is unavailable, users cannot smoothly borrow or return instruments. The inability to use instruments promptly not only wastes resources but also easily causes personnel delays and project schedule lag. Based on the above needs analysis, the team defined the requirements for this activity, as shown in Table 2.

3. Research and Reference

Research scope: Chinese Electric Power Science and Technology Achievement Database, Chinese Science and Technology Journal Full-text Database, Chinese Patent Database, Chinese Enterprise Product Database, Chinese Academic Thesis Database. After research, no materials were found on using QR code recognition technology to improve information query speed in the thermal power commissioning industry. Proposed innovative idea: By observing mobile payment models, train ticket information, advertising boards, and product packaging, as shown in Figure 2, the team discussed whether QR codes could be used as an information storage medium.

This topic aims to design a convenient and economical storage medium. The emergence of QR codes fully meets the team's needs for modern instrument management. They are portable, small in size, and can store a large amount of information. By scanning with a mobile app that has QR code recognition functionality, users can access information including uploaded Chinese and English user manuals, calibration reports, operation videos, drivers, HS codes, fixed asset numbers, and after-sales information. With reasonable application, instrument users can modify some information after reading the QR code, enhancing resource sharing between users and administrators.

4. Technical Challenges

5. Determining the Topic

Based on the topic requirements and research results, the team focused on programming design, real-time transmission, and permanent use as core technologies, confirming the topic as "Using QR Code Management to Reduce Instrument Information Query Time."

Setting Goals and Feasibility Analysis

1. Setting Target Values

- Instrument users' information query time will be reduced by 95%;

- QR code information coverage will be increased to 100%;

- Paperless office operations will be achieved, and the accuracy rate of outbound/inbound information will be increased to 99%.

2. Goal Feasibility Analysis

2.1 Theoretical Feasibility Analysis

The team envisions that through QR code recognition functionality, various types of pre-entered information within the QR code can be accurately identified. As long as there is network access, users no longer need to ask instrument administrators or manufacturers and can query all instrument information at any time. This will significantly reduce preparation time before instrument use and lessen the repetitive workload of instrument administrators.

2.2 Capability and Resource Feasibility Analysis

The team has 10 members, including 2 master's degree holders who have participated in large-scale informatization projects, 1 Ph.D. with strong quality control capabilities, 2 security administrators specializing in computer and information security, 2 members with experience in ISO9000 system construction and rich QC topic experience, and 3 R&D personnel with over 5 years of development experience. The team has a high overall professional technical level, a reasonable age structure, including experienced senior experts and young members with solid theoretical foundations, and strong overall technical capabilities. Based on the above analysis, the team's goals for this activity are reasonable and feasible.

Proposing Solutions and Determining the Best Solution

1. Proposing the Overall Solution

Team members, focusing on the innovation needs, used the "brainstorming method" to propose "Preparation and Use of QR Code Recognition Technology" as the overall solution. The overall process is shown in Figure 3. It adopts a core management approach centered on the team, collecting instrument information and creating QR codes, refining various functions within the QR codes, forming a complete closed-loop network from the team to deployment.

2. Solution Breakdown

The team held brainstorming meetings to break down functional requirements around the overall solution and selected the final development plan through multiple tests, as shown in Table 4.

2.1 Basic Information Testing

Basic information refers to the upload and recognition results of various file formats such as images, audio, video, text, PDF, WPS, CAD, and Office files. The team tested all the above formats multiple times, and the test results fully met the team's current needs, as shown in Table 5.

2.2 Data Submission and User Group Testing

In April 2020, the team used an AI platform to establish a QR code information recognition module. Since this module involves new functions such as instrument information query, fault reporting, borrowing and returning, and management, and considering that instrument users are distributed across the 25-65 age range, the team invited 30 people of different ages to participate in practical and repeated tests. The practical test topic was "Scan the QR code of the power frequency withstand voltage test equipment and submit outbound information," and the repeated test topic was "Scan the QR code of the power frequency withstand voltage test equipment and read the English manual," accurately recording the time taken for "information submission" and "information query" in completing the two topics.

Through overall scanning and information submission time tests on 30 people of different ages, it was found that regardless of the mobile phone brand or the use of faster 5G signals, the phone's quality did not affect the time required for various operations. The average time from the mobile phone camera recognizing a QR code to the QR code being read was 2.44 seconds. The average time to find the required "English manual" among numerous elements was 5.39 seconds. The "Outbound Record Form," which can replace the administrator's paper records, took an average of 26.64 seconds to fill out once. Figure 4 shows the trend of scanner age versus time taken. It can be seen that the key factor affecting the duration of an operation is the user's age. As the user's age increases, the time required for each operation also increases. When recording data, the team found that older users almost always took longer to complete the test tasks due to difficulty seeing the information displayed on the screen, resulting in slower information filling and searching. Taking "submission time" as an example, users under 45 took an average of 20.37 seconds to submit information, while users aged 45 and above took an average of 34.84 seconds. However, among the tested users, all 30 people completed the operations independently without seeking assistance from team members.

Comparing the results of the 30 tested individuals showed that although age and time taken were proportional, all users could complete the operations independently without seeking help from team members, and the average time for each operation was very impressive. Partial functionality has been achieved.

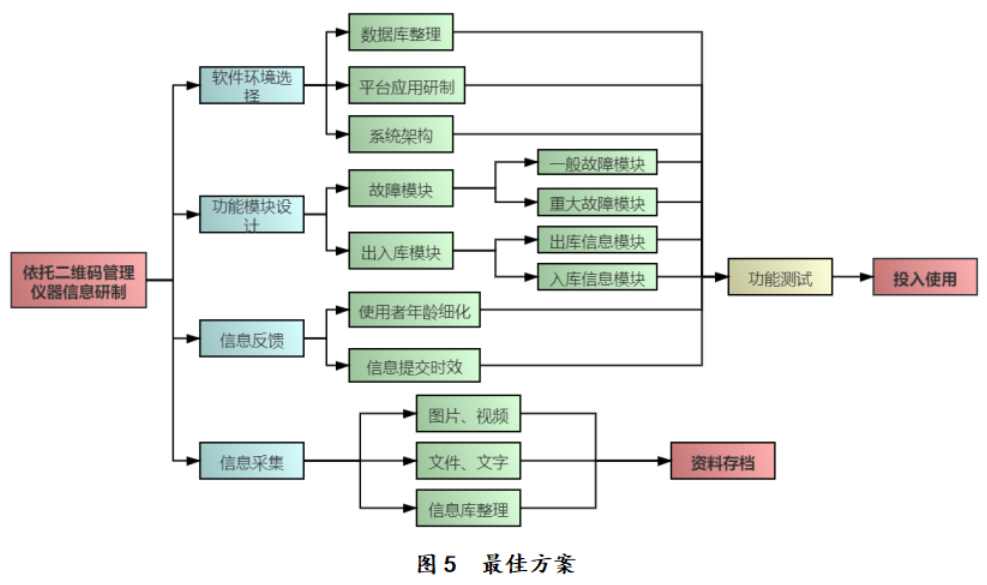

3. Determining the Best Solution

Team members conducted a detailed analysis and comparison of existing solutions and selected the best solution, as shown in Figure 5.

Developing Countermeasures

Based on the best solution, the team developed a countermeasure table according to the 5W1H principle. Specific countermeasures are shown in Table 9:

Implementing Countermeasures

According to the countermeasure table, we organized team members to implement step by step.

1. Uploading Instrument and Accessory Images

For a set of test instruments, the most reliable way for users to determine if it is what they need is to view the actual object. While inspecting the object, it is still necessary to check if the accompanying spare parts and accessories are complete. Therefore, in the information collection process, the completeness and angles of instrument and accessory images directly affect debugging personnel's judgment of their usability. When collecting instrument images, the team needs to include the instrument's overall appearance, nameplate, external packaging, and accessories.

Conclusion: After upload testing, images in JPG, PNG, JPEG, and other formats can be edited and uploaded to the QR code, and all can be displayed after scanning. Partial functionality has been achieved.

2. Uploading Instrument Chinese and English Manuals and Calibration Reports

With current technological advancements, instruments required by various specialties are becoming more precise and complex. Moreover, commissioning projects are spread across countries worldwide, often facing owners, construction teams, and supervisors from different nations. Many users must use instruments without prior training, causing significant difficulties. Therefore, a complete set of Chinese and English operation manuals or operation videos is crucial for users. Thus, team members strive to collect operation instructions for each instrument, meeting users' actual needs in projects and fulfilling owner inspection requirements, greatly improving work efficiency.

After instruments are used or stored for a period, the measurement results of instrument reagents may drift slightly, no longer providing accurate measurement results. Without calibration, the accuracy of test data cannot be determined, rendering the instrument useless and losing its practical significance. Team members scan paper-based Calibration Reports issued by metrology units into electronic format files. This facilitates inspections by relevant units, allowing immediate provision upon inspection, and enables users to know whether various parameters of the instrument measurement have deviated and what the correction value is in case of deviation.

Conclusion: After upload testing, manual files, operation videos, and Calibration Reports in Word, PDF, DOC, DOCX, MP4, and other formats can be edited and uploaded to the QR code, and all can be read after mobile phone QR code recognition. Partial functionality has been achieved.

3. Uploading Basic Instrument Information

Basic instrument information is a function that allows users to query the basic situation of the instrument after scanning the QR code. Basic instrument information is extensive. Based on its own needs, the thermal power commissioning industry has developed a set of information directories suitable for its own use, including: testable items, instrument model, number, supplier, after-sales phone, inspection status, manual status, asset ownership, rated voltage, capacity, current, and other key information. Considering the growing overseas market, information required for customs declaration during entry and exit, such as customs HS code, dimensions, and weight, is added (as shown in Table 10).

Conclusion: After editing and testing, tables can be created in the QR code editing area, and text within the tables can be edited. After mobile phone QR code recognition, the basic text information of the instrument can be read. Partial functionality has been achieved.

4. Uploading Safety Production Reminder Information

For personnel in the thermal power commissioning industry, the working environments are complex and diverse, such as live work in the electrical specialty, high-altitude work in the boiler specialty, confined space work in the turbine specialty, and hazardous material protection in the chemical specialty. When debugging in these environments, improper operation can easily cause personal injury to debugging personnel. Therefore, at the end of each QR code information, a "Safe Work, Constant Vigilance" column is added. The column content is divided into two types: safety warning slogans and GIF-format safety accident animations, reminding on-site personnel in the simplest form to strengthen self-protection and safety awareness.

Conclusion: After upload testing, GIF animations and JPG image format files can be uploaded to the QR