How to Solve the 3 Major Pain Points of Fixed Asset Management for SMEs

Original: https://cli.im/article/detail/2283

"Last year, our company lost 37 computers and 15 pieces of equipment, resulting in losses exceeding 500,000 RMB." This remark from a manufacturing business owner highlights a common dilemma faced by SMEs in asset management – asset loss and hidden costs continuously erode profits.

The Overlooked "Cost Black Hole": 3 Major Traps in SME Fixed Asset Management

Trap 1: Discrepancy Between Records and Reality, Profits Are "Stolen"

The flaws in traditional manual record-keeping make discrepancies between the actual quantity of assets and the book data a common occurrence. A food processing plant once over-depreciated assets by 120,000 RMB because the warehouse failed to update equipment scrapping records promptly. Another chain retail enterprise spent over 80,000 RMB on duplicate purchases of the same shelving due to unsynchronized transfer information between stores. These "invisible losses" often account for 1%-3% of a company's annual revenue, yet owners struggle to pinpoint the root cause.

Trap 2: Inefficient Inventory Counting, Doubling Labor Costs

"It took three people a full week to count 500 assets, and we still missed over 20 pieces of equipment." This complaint from an e-commerce company's administrative supervisor reflects the inefficiency of traditional inventory methods. Processes like paper form registration, cross-departmental coordination, and manual data verification consume significant time for administrative teams. More seriously, inefficient inventory leads to the accumulation of idle assets and frequent emergency purchases, further driving up operational costs.

Trap 3: Unclear Responsibilities, Difficult to Trace Asset Loss

Scenarios such as employees leaving without handing over equipment, shirking maintenance responsibilities, and premature equipment scrapping due to overuse stem from blurred lines of responsibility regarding "who uses it, who is responsible." An educational institution once had to bear the full repair cost exceeding 10,000 RMB for a damaged classroom projector because they couldn't trace the user.

How a Fixed Asset Management System Reduces Costs and Improves Efficiency

Data from market research firm IDC shows that implementing an asset management system can help enterprises reduce audit costs by 75%, lower spare parts inventory by 40%, decrease excess testing equipment by 20%, reduce equipment "disappearance" by 45%, and increase asset utilization rate by 30%. Below, using CaoLiao QR Codes as an example, we explain how to achieve cost reduction and efficiency improvement through the "One Item, One Code" approach.

One Item, One Code: Transparent Asset Information

Generate a unique QR code label for each fixed asset. Scanning the code allows viewing the complete profile, including asset information, purchase contracts, maintenance records, responsible person, etc.

- View basic asset information: Includes asset name, status, using department, responsible person, usage instructions, purchase date, etc.

- Update asset status: When information like the user or department changes, simply scan the code to edit and update, avoiding the need to reprint labels.

- Access usage instructions: View the asset's usage methods and precautions anytime, reducing misuse.

Scan-to-Count Inventory: Real-time Asset Status Monitoring

Update asset usage status in real-time by scanning QR codes with WeChat. No special hardware is needed; the operation is simple and requires no employee training, potentially reducing labor costs by 80%.

- Batch add records, reduce repetitive entry: Use the batch add records function; fill out the record once to apply it to all relevant assets.

- Asset status reports: Real-time statistics on asset usage status (e.g., in use, under repair, scrapped), allowing quick access to data on idle or scrapped assets.

Multi-level Permissions: Ensuring Data Security

Administrators can assign permissions based on roles, such as Administration, Department Head, Regular Employee:

- Owner/Boss: View asset overview in real-time, with support for exporting all data.

- Department Head: Manage only assets within their department; can update and view relevant content but cannot access cross-department information.

- Regular Employee: Scan codes to report repairs / request assets; historical actions are logged and traceable.

Data Statistics: Reducing Decision-Making Costs

All data can be viewed and exported. API functionality is provided for integration with existing systems, preventing data silos.

- View and export asset data: View detailed data for all assets in the workbench and export to Excel or PDF files as needed for archiving and sharing.

- Create visual reports: CaoLiao QR Code offers data push functionality to create visual reports for asset management, intuitively displaying key data such as asset distribution, utilization rate, depreciation trends, etc., to support management decisions.

How to Create Fixed Asset QR Codes

The following tutorial is suitable for anyone, with no usage barriers. Deployment for thousands of fixed assets can be completed within one day.

Step 1: Visit the CaoLiao QR Code Website

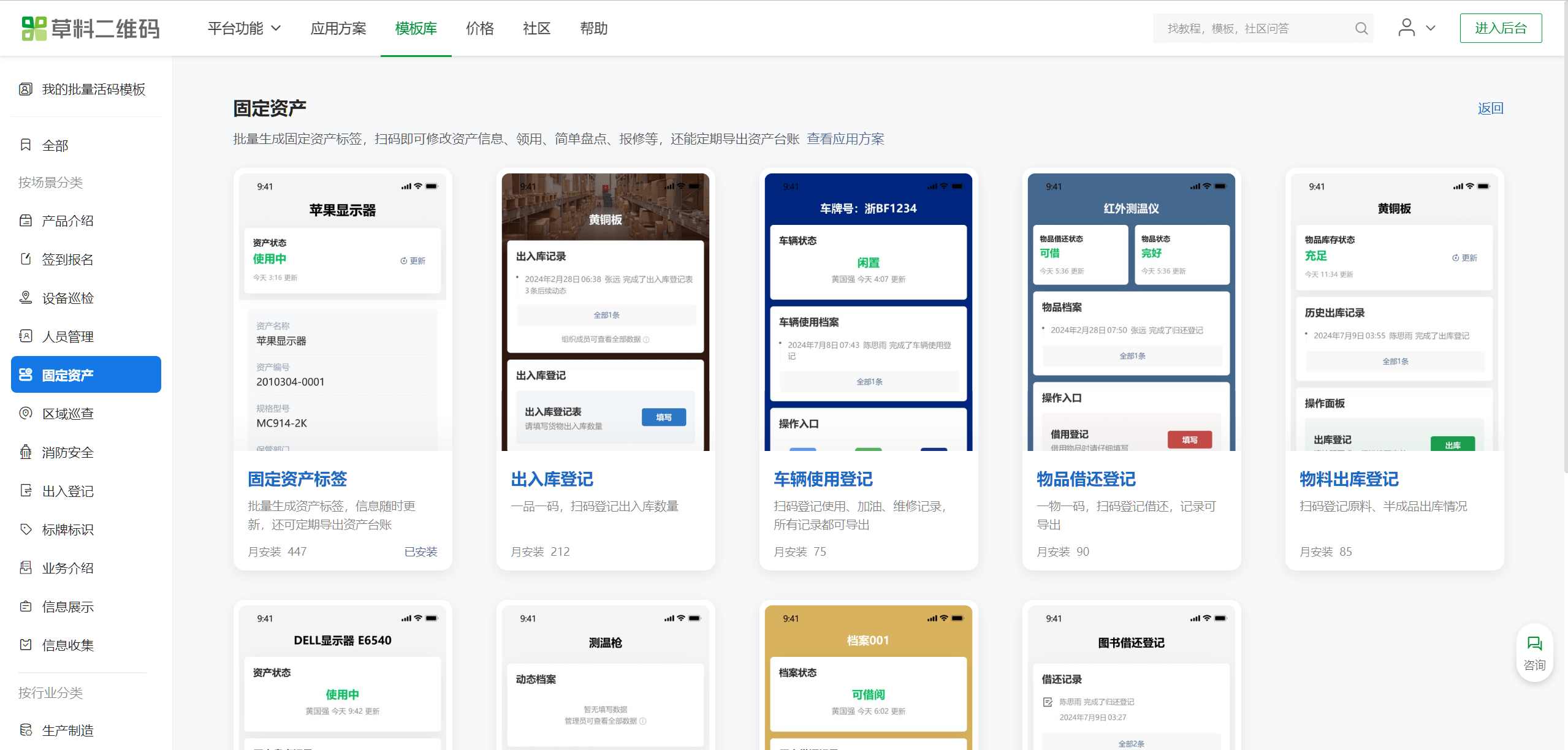

On a computer, go to the CaoLiao QR Code official website. Click on [Template Library], select the [Fixed Assets] category, choose a suitable fixed asset template, and start using it for free.

Step 2: Bulk Create Asset QR Codes

Each asset QR code contains basic information like asset name, number, storage location, asset status, and can also display physical photos. You can add other content such as text, videos, or files to the template based on your actual needs. Import your prepared asset ledger Excel file or specify the number of QR codes to generate them in bulk. Tip: Before importing data, organize your asset ledger by grouping assets by department or category, saving each batch as a separate Excel file.

Step 3: Bulk Print QR Code Labels

CaoLiao QR Code provides ready-to-use label layout tools. No need to download specialized software; open the webpage to apply label styles. Common asset label styles are provided. Select the appropriate style and printing method to download the corresponding print file. Connect to an office printer or label maker and use adhesive sticker paper for printing. Once printed, affix them to the assets to start using.

Summary

For SMEs, fixed asset management is not just a "cost burden" but also a hidden profit growth point. Compared to traditional fixed asset management systems which are often expensive, have high implementation costs, and long deployment cycles, CaoLiao QR Code can be set up for free, is simple to use, and allows for rapid deployment, making it an ideal choice for SMEs managing their fixed assets.