Fire Safety Inspection Frequency: How Often Is Appropriate?

Original: https://cli.im/article/detail/2285

A fire once broke out in a self-built residential house used for rentals in Ningbo, Zhejiang. Due to the failure of the fire alarm to trigger and the use of non-compliant fire extinguishers, the initial fire did not receive an alarm, and the extinguishers failed to function as intended. Ultimately, the tragedy resulted in seven fatalities. These recurring incidents serve as a stark reminder of the critical importance of fire safety inspection management.

Determining the appropriate frequency for fire safety inspections often poses a challenge for enterprise safety officers and managers. It involves not only the specific requirements of different locations but also considerations of labor costs.

Recommended Fire Inspection Frequencies for Different Locations

Based on the requirements of Appendix C of the "Code for Acceptance and Inspection of Fire Extinguisher Distribution in Buildings" (GB50444-2008), differentiated plans should be formulated according to the risk level of the premises:

| Location Type | Recommended Inspection Frequency | Key Basis |

|---|---|---|

| Office Buildings / Residences | Once per month | Routine fire risk, relatively low personnel density |

| Shopping Malls / Restaurants | Twice per month | High foot traffic, numerous electrical appliances, relatively high fire risk |

| Factories / Warehouses | Once per week | Concentration of flammable materials, complex equipment operation, high fire risk |

| Hospitals / Schools | Twice per month | High proportion of special populations, high priority for safety assurance |

Adjusting Inspection Frequency Under Special Circumstances

It is important to note that fire inspection frequency is not fixed. Adjustments should be made promptly under the following three circumstances:

- Equipment Aging: As fire protection facilities and equipment age and show signs of wear, the inspection frequency should be appropriately increased to promptly identify potential failures.

- Seasonal Changes: For instance, during dry autumn and winter seasons when the likelihood of fires increases, inspection frequency needs to be heightened.

- Before Major Events: Before large-scale events such as major promotions in shopping malls or large gatherings in schools, where large numbers of people congregate, fire safety inspections must be strengthened to ensure the event proceeds safely and orderly.

How to Improve Fire Management Capabilities

Traditional fire inspection methods rely on manual record-keeping, which is not only inefficient but also prone to issues like perfunctory checks and missed inspections. For enterprises, introducing digital management tools is an effective way to enhance the efficiency of fire inspections. However, for most small and medium-sized enterprises (SMEs), procuring a large, comprehensive fire management system might involve long deployment cycles, high costs, and underutilization of features, leading to a series of resource wastes. Companies can choose a more lightweight management system based on their actual manpower and budget. For example, using CaoLiao QR codes for fire safety inspection management.

QR Codes: The Optimal Choice for Fire Safety Management in SMEs

As a lightweight and easy-to-implement solution for fire safety management, QR codes offer significant advantages over traditional inspection methods:

- Standardize Inspection Methods: Inspectors simply scan the QR code on equipment like fire extinguishers and follow the preset checklist item by item. Combined with anti-fraud features that require real-time uploads of on-site photos, this effectively prevents fake inspections.

- Automatic Alerts for Abnormalities: Once an inspection reveals a fault, the system automatically alerts the administrator, facilitating timely follow-up and resolution, while also recording the subsequent handling process.

- Create Inspection Plans and Missed Inspection Reminders: By setting up inspection plans, alerts are sent when inspections are not completed on time, ensuring tasks progress as scheduled. Administrators can also clearly grasp the completion status of inspection tasks.

- Unified Data Management: All inspection records are stored in the management backend. Administrators can view and trace records at any time, and data export is supported for convenient analysis and summarization.

Tutorial: Creating Fire Inspection QR Codes

Step 1: Access the CaoLiao QR Code Platform

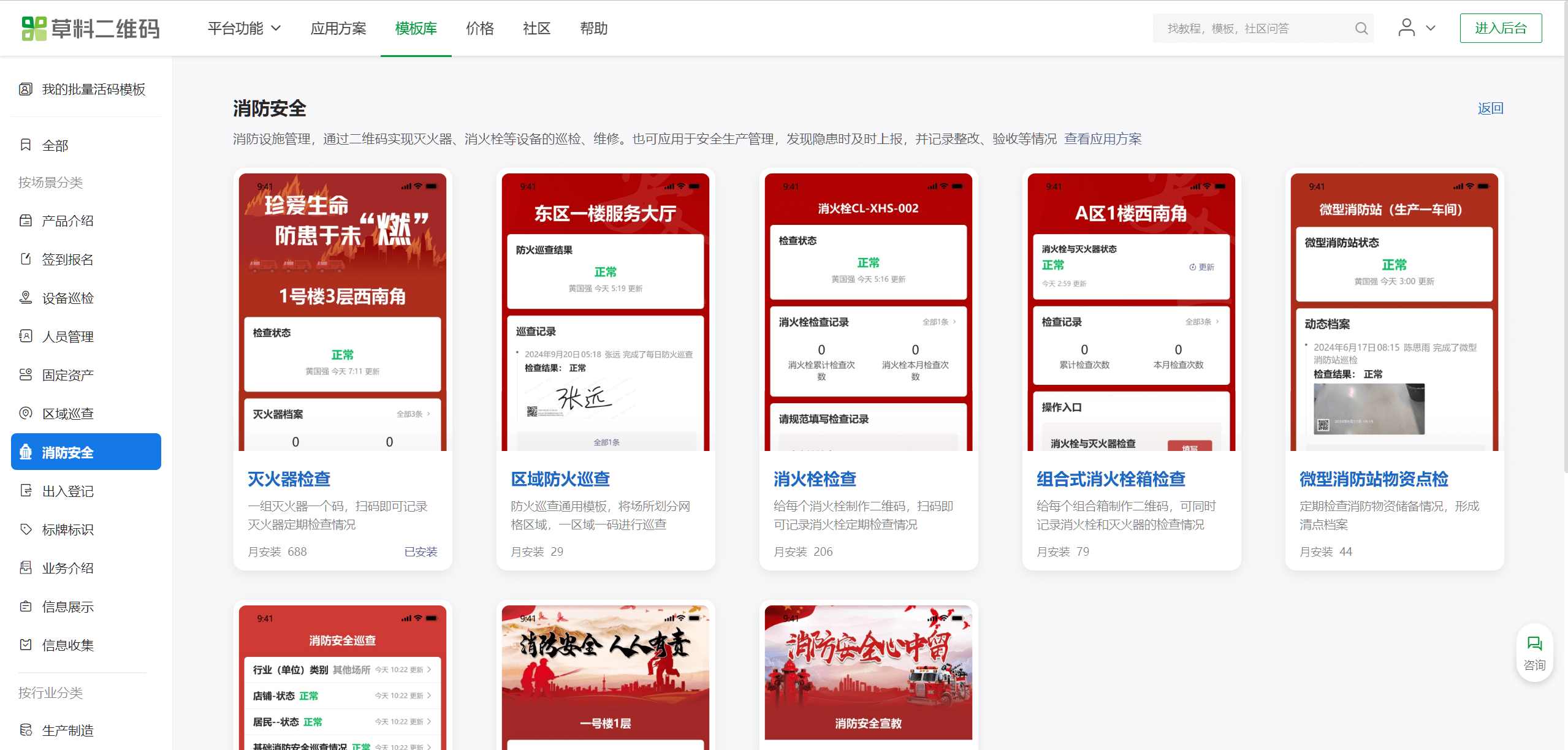

Visit the CaoLiao QR Code official website on your computer, enter the template library, and select a suitable fire inspection template, such as the "Fire Extinguisher Inspection" template.

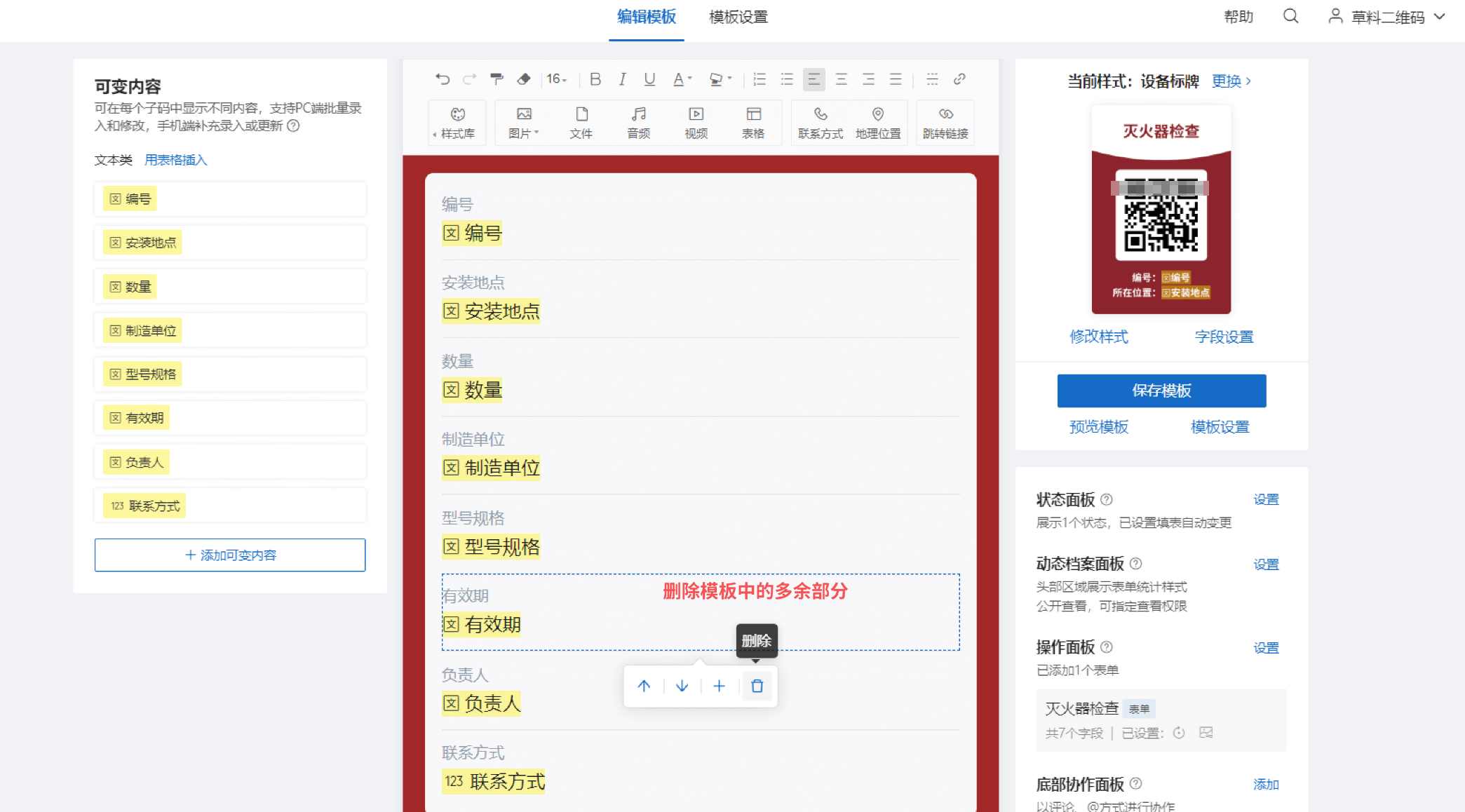

Step 2: Modify the Fire Inspection QR Code Template

After entering the template editor, modify the template content according to your actual needs. For example, you can add specific fire inspection items, such as whether the fire extinguisher pressure is normal, whether the fire hydrant valve is leaking, etc. Set key items as mandatory to ensure inspectors do not overlook important content.

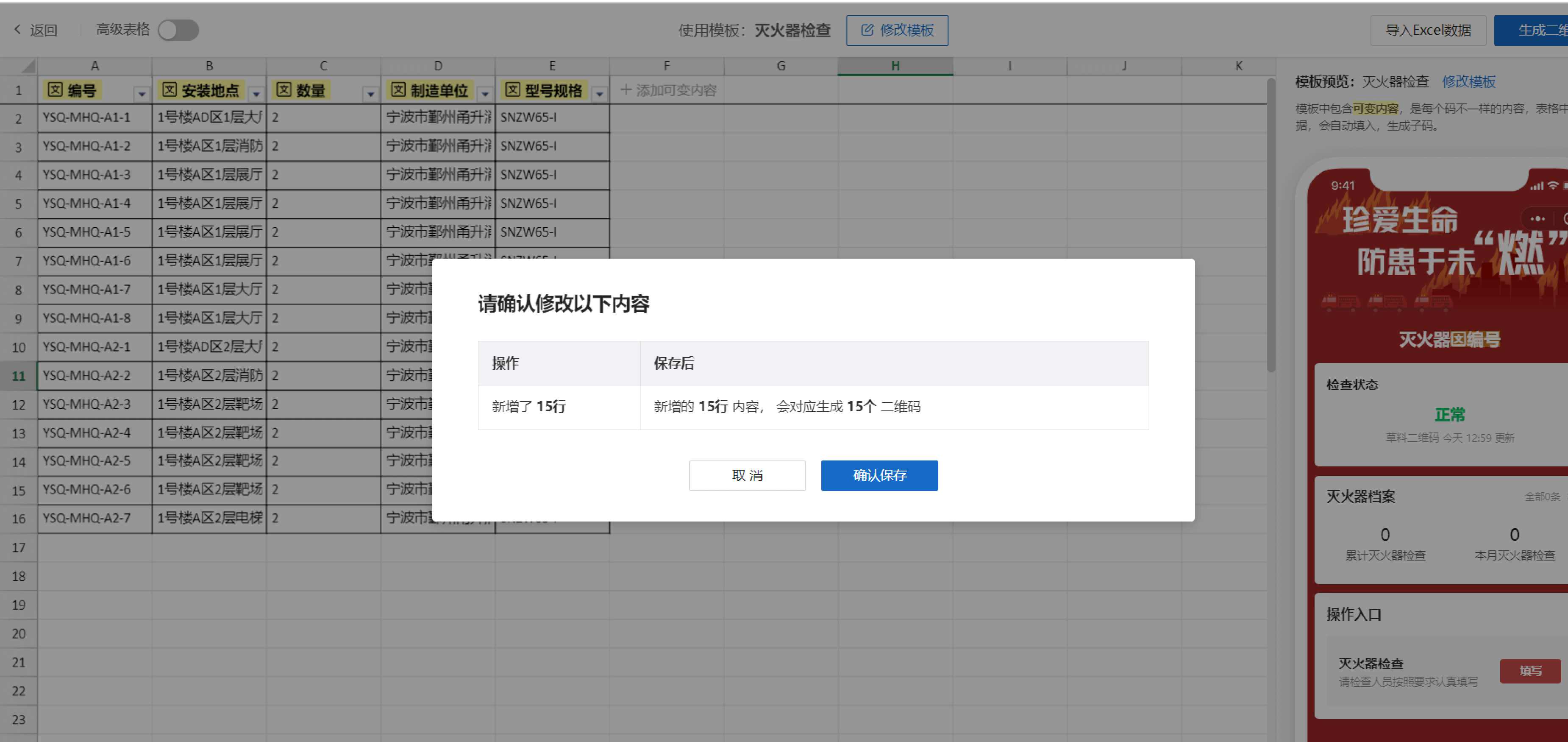

Step 3: Generate Fire Inspection QR Codes in Bulk

Import the basic information of fire extinguishers and hydrants. The system will generate QR codes in bulk based on this list. After generation, you can configure permissions, assigning operational rights according to different personnel responsibilities. For instance, administrators have the highest permissions to view, modify, and delete all fire inspection data; regular inspectors can only upload and view inspection records; maintenance personnel can receive alerts for abnormal situations.

Step 4: Print and Post the QR Codes

After generating the QR codes, select the desired label style. The labels can be downloaded and printed. They can be printed as adhesive stickers or on hard cards with holes for hanging. Place them conspicuously on the corresponding fire protection equipment (like fire extinguishers, hydrants) or inspection areas. Once deployed, on-site personnel can scan the code to complete inspections.

Numerous Enterprises Standardize Fire Inspections Using QR Codes

Currently, many enterprises have used CaoLiao QR codes to create fire safety QR codes for inspection management, achieving significant results. For example:

- Yanfeng Adient (Ningbo) Seating Co., Ltd.: Equipped hundreds of fire hydrants and extinguishers within the plant with exclusive QR codes. Inspectors scan the codes to record each inspection. All information is aggregated and statistically analyzed on the platform, making fire inspections more standardized, records more complete and comprehensive, and data storage and viewing extremely convenient.

- Guizhou Aerospace Electronics: Adopted a combination of the "CaoLiao QR Code Mini Program + QR codes" to achieve comprehensive inspections of fire protection equipment like fire extinguishers and hydrants.

- Western Venture Ningdong Railway Company: Applied the CaoLiao platform to establish a "one code, one file" pilot for fire protection facilities, launched a "one code management" application matrix, and initiated a "digital" transformation of the information management model.