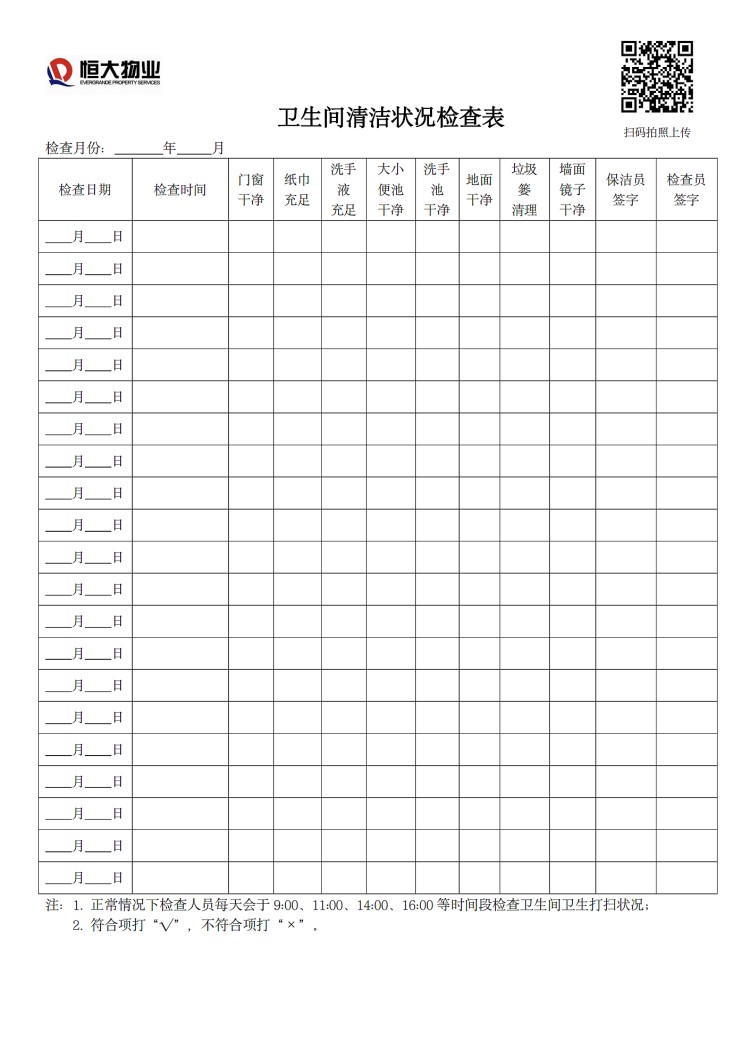

Cleaning Work Management

Cleaning staff scan QR codes to report hygiene conditions in their respective assigned areas. Managers can monitor the situation in real-time through the workbench and conduct inspections. Inspection records are automatically summarized and can be viewed or exported at any time.

Basic Information

- Monthly Installations: 11021

- Monthly Visits: 23799

- Original: https://cli.im/template/detail/70126782

Case Label Images

Usage Instructions

I. Applicable Scenarios

Suitable for daily cleaning and supervisor inspections in public areas such as properties, parks, shopping malls, office buildings, factories, schools, and hospitals. QR codes are posted at specific points, cleaning staff scan them to record work, supervisors conduct spot checks and initiate corrections, and the public can scan to supervise.

II. Preparation Before Use

Start by selecting a few points for trial, such as the first-floor restroom and second-floor restroom, dividing them into areas for testing.

III. Quick Start

1. Generate Equipment QR Codes

Choose a QR code generation method:

- Bulk QR Codes Generation (Recommended): Use when inspection requirements are consistent across areas, e.g., all restrooms in a building. Manage all points with one bulk template, fill in point information in the spreadsheet, and generate all QR codes for each point in bulk.

- Single QR Code Generation: Use when inspection requirements differ by area, e.g., meeting room cleaning vs. restroom cleaning require different standards, necessitating separate single code generation.

2. Label Download and Posting

- Trial Phase: Print on A4 regular paper → affix on-site with transparent tape.

- Formal Use: If aesthetics and durability are required, refer to the Label Material Recommendation Guide before formal use.

3. Staff Training and On-site Trial

- Training Materials for Cleaning Staff: Cleaning Staff Operation Guide

On-site Trial: Arrange for each cleaner to scan the code and submit one "Incomplete" work record. Test the notifications and forwarding functions to ensure administrators receive the messages.

IV. Advanced Usage

1. AI Smart Form Filling and Review

Starting from the Advanced edition, AI smart form filling mode is available. Define on-site cleaning standards clearly; administrators can pre-set shooting content through review rules to achieve institutionalized supervision. Learn more

Example: Administrators specify that photos must capture the floor, sink, and trash bin. Cleaning staff take photos as required on-site, AI automatically reviews if the shooting meets requirements, staff confirm accuracy, and submit the record.

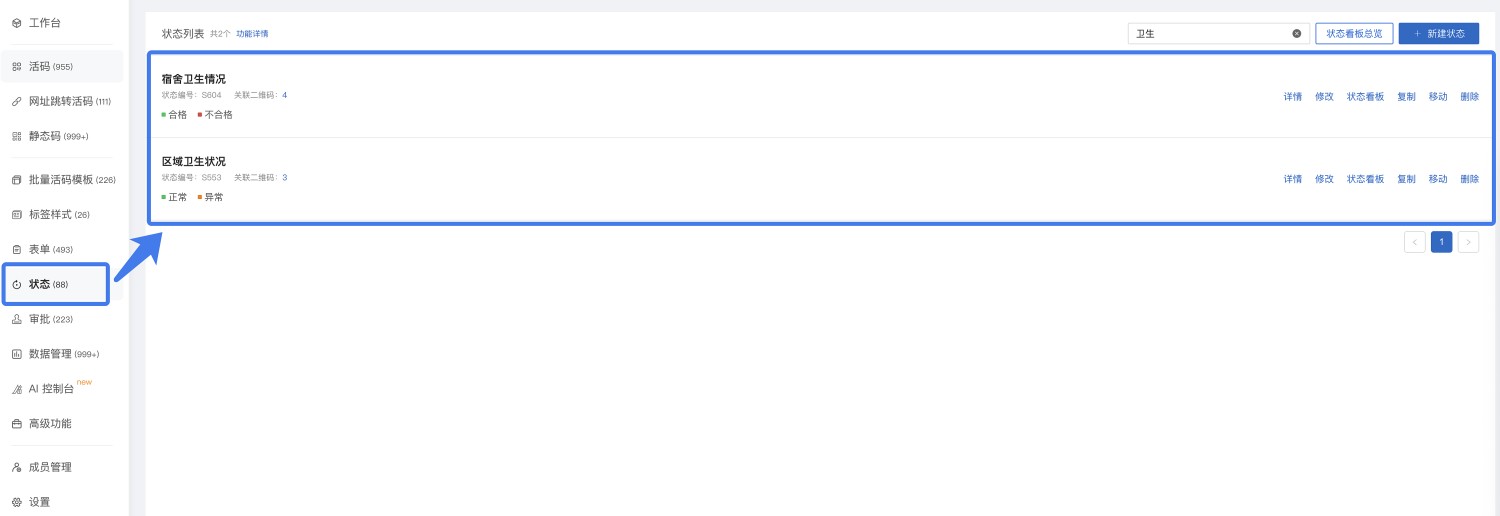

2. View Overall Hygiene Status of Areas

- Status Dashboard: The status dashboard on the QR code displays the real-time hygiene status of the area for easy viewing.

- Overall Situation: Administrators can view the distribution of hygiene status across areas in the Status List on the mobile or desktop workbench. View details

V. Frequently Asked Questions

1. How to Avoid Missed Inspections?

Answer:

- Create Inspection Plans: Establish periodic inspection plans, e.g., Daily Inspection Plans, specifying areas that need daily checks.

- View Plan Reports: Administrators can view Plan Reports on the mobile workbench to understand inspection completion status.

- Overdue Reminders: Before inspections become overdue, the system automatically reminds administrators via WeChat about areas not yet inspected, facilitating timely scheduling.

2. How to Set Up Abnormal Report Review Before Correction?

Answer:

- Enable Review Function: After an abnormal report is submitted, notify managers for review first.

- Review Process: Only after approval will the system automatically remind the responsible person for follow-up correction; unapproved abnormalities are rejected, requiring no action, avoiding excessive invalid reminders.

3. How to Set Operation Permissions?

Answer:

- Permission Management: Configure so that only specific personnel can view QR codes, change inspection results, fill out inspection forms, view data, etc., ensuring data security and operational compliance.

4. How to Improve Inspection Efficiency?

Answer:

- Quick Updates: After patrolling, inspection personnel can manually update inspection results, supporting image uploads and text descriptions.

- Quick Operations: Long-press the inspection result area to quickly update the inspection time, simplifying the operation process.

- Permission Control: If manual result changes by inspection personnel are not allowed, restrict this in the permission settings.

5. Can Subsequent Forms for Abnormal Reports Be Linked with Processing Progress?

Answer:

- Current Limitation: Linkage is not currently supported. After maintenance personnel fill out the maintenance form, they need to manually update the processing progress.

- Data Filtering: Administrators can filter and view data based on processing progress in the workbench to track correction status.

Related Customer Cases

[Wenzhou Central Hospital: Creating "Electronic IDs" for Hospital Firefighting Facilities to Standardize Inspection Procedures](https://cli.im/client/detail/1743 "Wenzhou Central Hospital: Creating "Electronic IDs" for Hospital Firefighting Facilities to Standardize Inspection Procedures")