Equipment Inspection QR Code

Original: https://cli.im/case/detail/1688

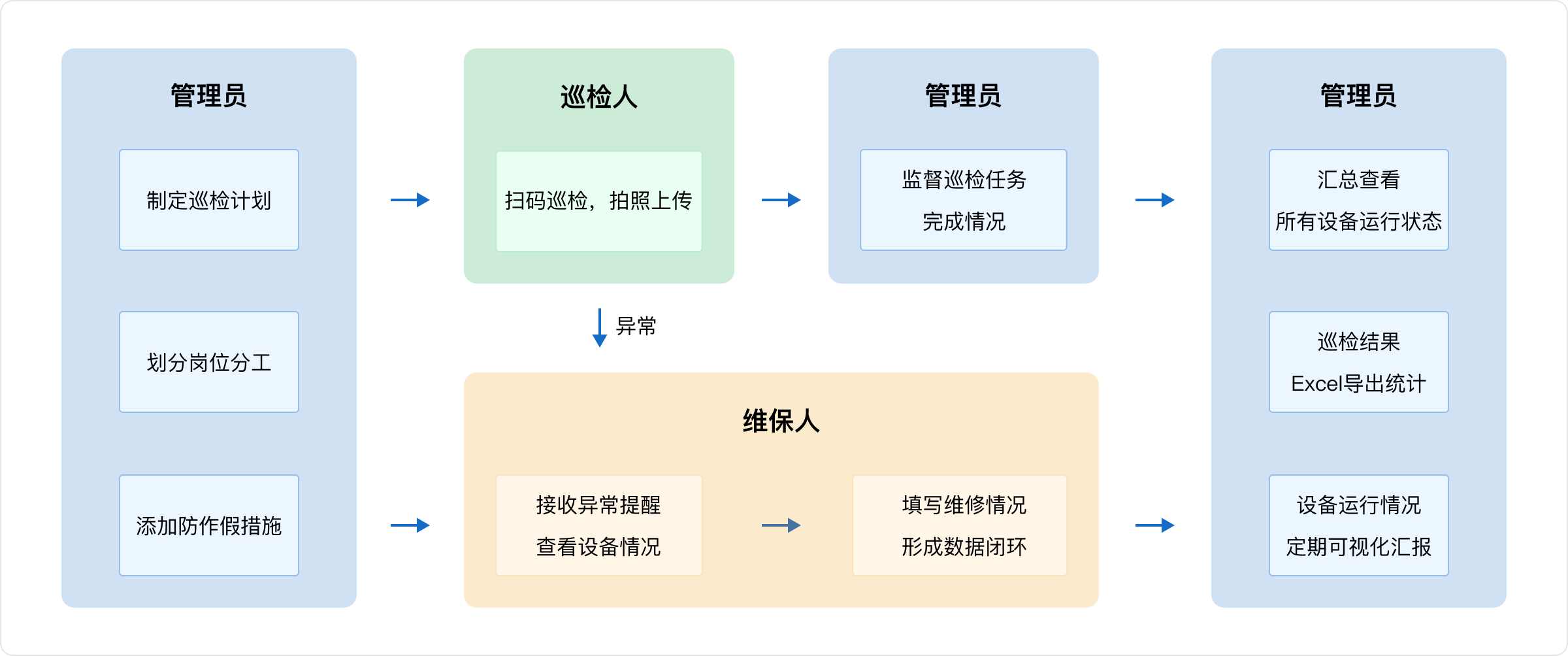

Solution Overview

By placing a unique QR code on each piece of equipment, the QR code serves as the equipment's electronic record, documenting basic information and all inspection, maintenance, and modification logs.

- Inspection Personnel: Scan with WeChat, check items, take photos on-site – easy to use without training.

- Maintenance Personnel: Receive real-time alerts for abnormal results; log maintenance details directly after the inspection record.

- Management Personnel: Data is no longer scattered. Use dashboards to identify missed inspections or anomalies, and export data to Excel for analysis or visual reporting.

This QR code inspection solution is versatile and can be used to build inspection systems for any equipment. It features quick deployment, low cost, and requires no training for frontline staff, making it ideal for small and medium-sized enterprises to rapidly implement digital equipment management.

If you are already familiar with the workflow, you can jump directly to the setup tutorial to start building your QR code inspection system.

Workflow

1. Periodic Scanning and Reporting by Inspection Personnel

- Inspect via WeChat Scan: Place QR codes on equipment; no need for paper forms or additional apps.

- Standardized Check Item Completion: Check normal items directly; provide detailed notes for issues – saves time and ensures quality.

- Photo Documentation: Forms support uploading on-site photos to visually record equipment status.

- Easy Filling: Auto-fill repetitive content; use speech-to-text for descriptions to avoid typing.

Anti-Fraud Measures

- Location Restrictions: QR codes cannot be accessed if the inspector is beyond a certain range from the equipment, ensuring on-site inspection.

- Mandatory On-Site Photos: Equipment photos must be taken and uploaded on the spot; uploading from the phone gallery is disabled.

- Photo Watermarks: The system automatically adds inspection time, inspector name, and phone location to photos as proof.

- Blockchain Notarization (Optional): Inspection data is stored on the blockchain, making it immutable. This can serve as judicial evidence for future traceability.

2. Maintenance Personnel Handling Equipment Failures

- Real-Time Alerts for Anomalies: Abnormal results are pushed in real-time to maintenance supervisors, who can immediately view fault details without waiting for phone reports, enabling faster repair responses.

- Closed-Loop Fault Handling: Maintenance records are logged directly under the original inspection record, ensuring data correlation, clear responsibility, and easy traceability.

Equipment Knowledge Accumulation

- AI Interactive Q&A: No more worries about training new workshop staff or searching for manuals. Starting from the Advanced version, upload equipment manuals to the QR code and enable AI interpretation. Staff can scan and ask about equipment operation or maintenance issues, and the AI will provide answers like a "veteran technician." What is AI interpretation?

3. Periodic Summary and Analysis by Management Personnel

Pre-Inspection

- Automatic Task Scheduling: Set inspection cycles and generate inspection schedules with one click to reduce omissions.

- Clear Role-Based Permissions: Define roles for inspection, maintenance, and management with strict controls over who can view and fill out forms.

- Departmental Data Isolation: Partition data by workshop/department to keep inspection records separate, ensuring privacy compliance and facilitating rollout.

During Execution

- Approaching Deadline Alerts: The system automatically alerts management when inspection tasks are nearing their deadlines.

- Mobile Access: Check overall inspection task completion status and identify omissions directly from a mobile phone.

- Monitor Equipment Status: QR codes display the latest equipment status in real-time; the mobile workbench provides an overview of all equipment operational status.

Post-Inspection

- On-Demand Record Export and Archiving: Inspection records are permanently stored in the cloud and can be exported to Excel by cycle/department for statistical analysis and archiving.

- Zero-Code Visualization: Connect data to visualization tools in 5 minutes; automatically generate charts after setting up a dashboard, saving time and effort in reporting.

Version Selection

1. Free Version for Basic Use

For pilot phases or small-scale use, start with the Free version to create QR codes and experience the basic QR code inspection workflow.

2. Paid Versions for More Granular Management

When the number of devices increases or you begin wider rollout, and have specific needs such as "equipment fault notifications need to be sent to designated personnel," "need to manage equipment by workshop/department," or "large monthly volume of equipment inspection photos," consider upgrading to a paid version.

| Requirement | Free Version | Advanced Version | Flagship Version |

|---|---|---|---|

| Scan for inspection, run the process | Unlimited QR codes, scan counts, record entries | ||

| Different devices, different responsible persons | - | ✅ | ✅ |

| Real-time fault alerts | Only the administrator | Can alert maintenance group | Can alert maintenance group |

| Multi-level approval | - | ✅ | ✅ |

| Approval count limit | 1200 times/year | 6000 times/year | 24000 times/year |

| Original equipment photos | Last 5000 images | Last 5000 images | Unlimited |

| Recommended Users | Single workshop/venue Small-scale pilot | Small teams with fewer equipment types and managers | Enterprises with multiple workshops/venues and functional management |

| Price | - | 1280 RMB/year | 2680 RMB/year |

For detailed version comparison and purchasing advice, click here to view.

Setup Tutorial

The following are detailed step-by-step tutorials to help you build your equipment inspection system from scratch.

1. Basic Process

The basic process for using QR codes for equipment inspection consists of 5 steps. Follow these steps to complete a simple setup and use of a QR code equipment inspection system.

| Step | Tutorial |

|---|---|

| Generate QR Code | Click to View |

| Print and Affix QR Code Labels | Click to View |

| Scan QR Code for Inspection | Includes operator guide for inspection personnel: Click to Download |

| Fault Handling | Includes operator guide for maintenance personnel: Click to Download |

| Summary, Export, and Print of Inspection Records | Click to View |

2. Advanced Usage

The following are advanced processes for after you have established the basic workflow, which can be configured according to actual needs.

| Step | Tutorial |

|---|---|

| Create Inspection Plan | Click to View |

| Define Role Division | Click to View |

| Add Anti-Fraud Measures | Click to View |

| Real-Time Alerts for Equipment Faults | Click to View |

| Implement Data Isolation by Subsidiary/Department/Workshop | Click to View |

| Data Visualization and Reporting | Sync to Tencent Sheets, Sync to other visualization tools |

User Cases

1. Bull Group: Saved 200,000 RMB in System Procurement Costs

Built an equipment management system for less than 3000 RMB, achieving results comparable to professional MES systems. View Details

2. China Resources Group: QR Codes Replaced 90% of Paper Checklists

Saved significant paper and manual statistical costs; the system won the "China Resources Group EHS Management Excellence Operation Gold Award." View Details

3. Lite Aviation: One Code Replaces 4 Major Management Platforms

Employees used QR codes to build multiple management platforms including TPM, quality inspection, hidden hazard investigation, and suggestion submission. View Details

For more cases, click here to view.

Frequently Asked Questions

1. Can we set this up ourselves without an IT department?

- Absolutely. The CaoLiao platform is specifically designed for frontline managers, requiring no programming or coding knowledge. Users simply drag and drop the required functional modules and adjust settings according to their needs to complete the setup. Anyone can use it.

2. What is the user scale and size of CaoLiao?

- Since its founding in 2011, CaoLiao QR Code has focused exclusively on QR code technology. To date, it has over 15 million registered users and over 500 million Mini Program users, ranking among the top 50 in China for Mini Program user scale. CaoLiao was the sole invited drafting unit for the national standard "Commodity QR Code" (Standard No. GB/T 33993-2017) and participated in its compilation. System security, reliability, and stability are fundamental guarantees from CaoLiao. Click for details.

3. How does CaoLiao ensure the security of inspection data?

- As a professional SaaS product, CaoLiao prioritizes user data security, providing reliable, secure, and compliant cloud services. The CaoLiao product has passed the Level 3 classified protection of cybersecurity assessment and DCMM Level 2 certification. We also have many users from government departments, state-owned enterprises, and other organizations with high data security requirements. If you have concerns, please click for more details.

4. Can I try it first and buy the paid version only after the pilot is successful? What are the implications?

- Yes, you can. Upgrading your CaoLiao version only adds more benefits and will not negatively impact QR codes already in use. As long as you do not delete them, the inspection records you have already filled out will be permanently saved and will not be lost.

5. How do I get started?

- You can follow the Setup Tutorial above to start from scratch. Alternatively, click the template library below, select a suitable equipment inspection template, modify the template content and configuration according to your actual needs, and save to generate the QR code.

Start Building

The following templates are based on real user practices, helping you quickly leverage peer experience and reduce setup costs.

[

Equipment Inspection and Maintenance

Universal template, suitable for common equipment. Scan to start inspection.

Use Template](https://cli.im/template/detail/121463037)[

![Medical Equipment Daily Management](https://blogcdnimg.clewm.net/2025/01/Frame-2018776180_17373447091042.png?x-oss-process=image/resize,h_330/format,gif/sharpen,100/interlace,1/