Manufacturing

Original: https://cli.im/case/detail/1900

Scan to Use

Simplified Production Management

Manage equipment, inspect for hazards, handle personnel – all easily accessible Build with zero code, reduce costs and improve efficiency

Suitable for Various Scenarios in the Manufacturing Industry

Based on real user experience, the following templates are ready to use

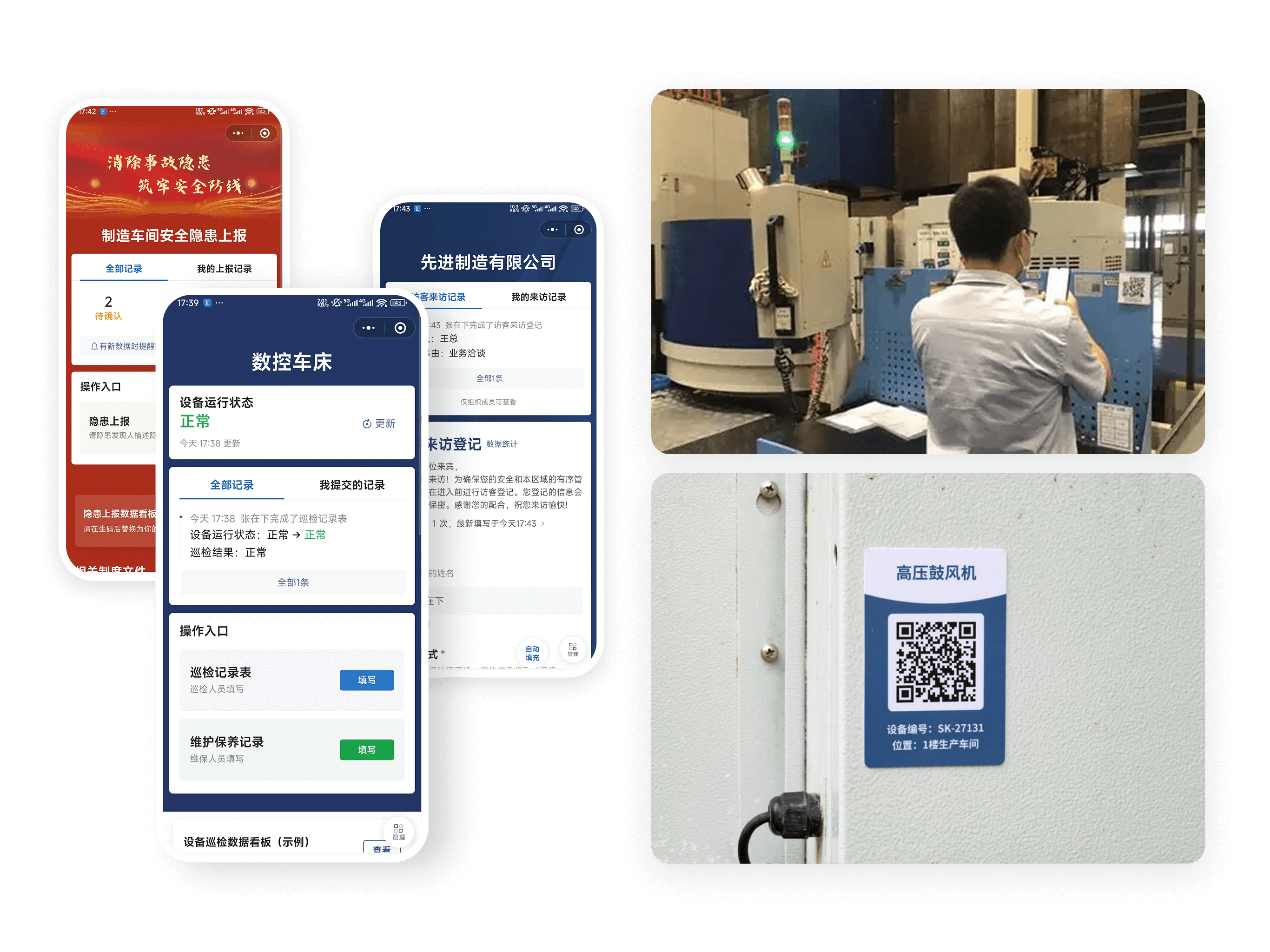

Equipment Inspection

Regular checks prevent falsification

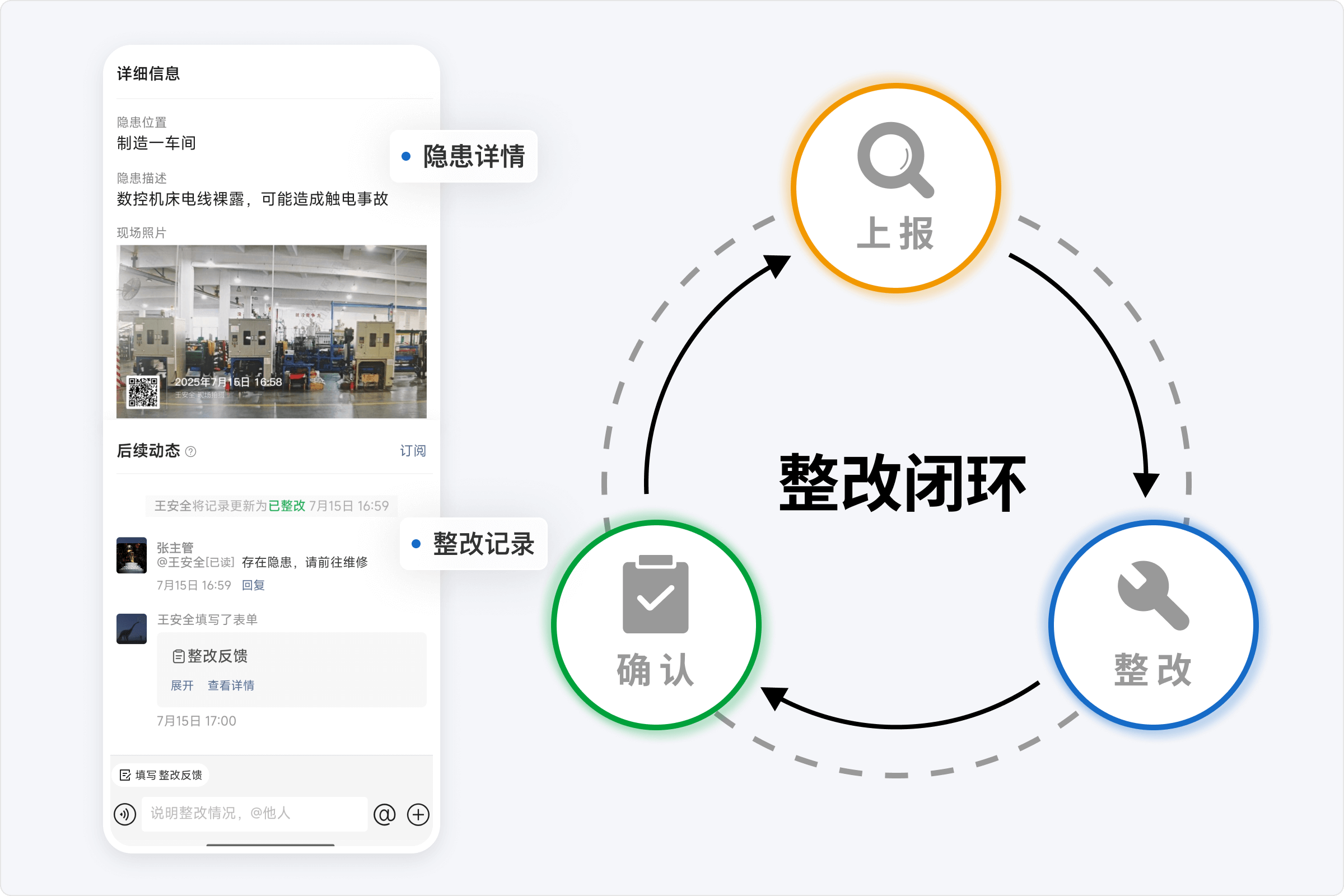

Hazard Identification

Report promptly, closed-loop handling

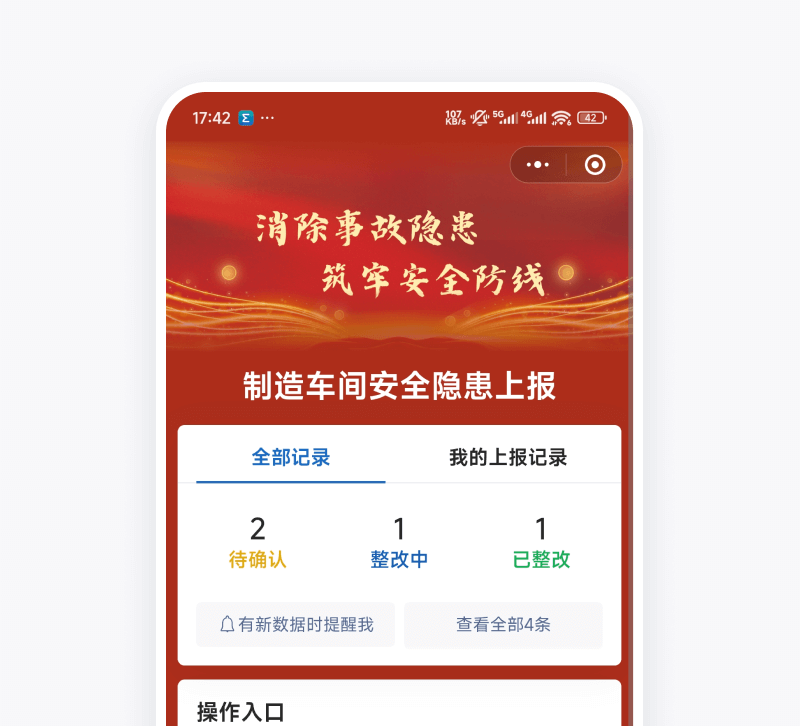

Safety Education

View by scanning, anytime, anywhere

Personnel Management

Identity verification, site access control

Attendance Check-in

Location-based check-in, authentic information

Hazardous Waste Labeling

Ensure compliance with new national standards

Inventory Registration

One code per item, scan to register

More Scenarios

View more usage methods

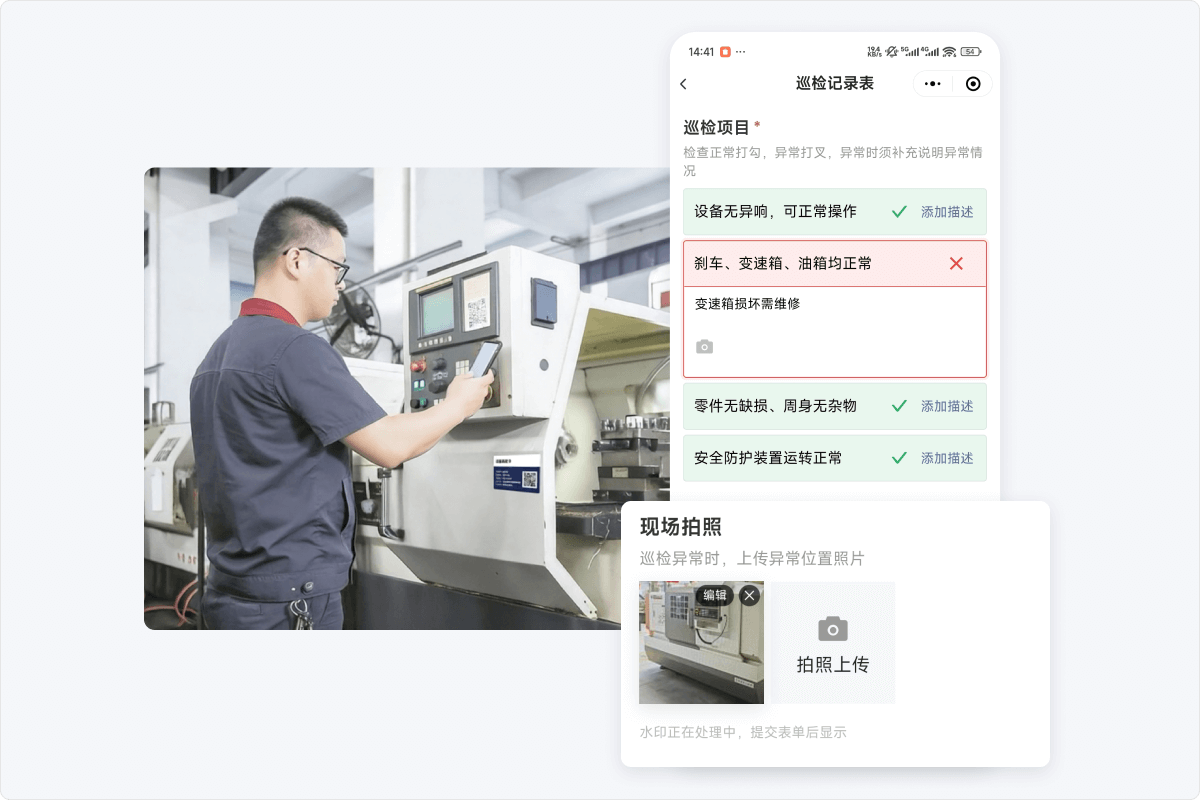

Complete Inspection Tasks with Guaranteed Quality and Quantity

Easy Employee Adoption

Use by scanning with WeChat, no app installation required

Multiple Anti-Falsification Measures

On-site watermarked photos, location capture, etc., ensure authentic records

Reduce Downtime

Real-time alerts for equipment anomalies, quick response for inspection and repair

Real-time Online Supervision

Records sync automatically, administrators grasp the latest status via the dashboard in real-time

Select Template to Generate Code

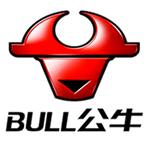

Quick Hazard Response to Reduce Risk

Report Anytime, Anywhere, Flexibly and Conveniently

Free from the constraints of pen-and-paper records; report hazards immediately by taking out your phone

Photo Documentation, Fast and Accurate

Scan to photograph the hazard scene, eliminating cumbersome text descriptions—a picture is worth a thousand words

Closed-Loop Management: Report — Rectify — Confirm

One hazard, one closed loop, leaving no risk unaddressed

Select Template to Generate Code

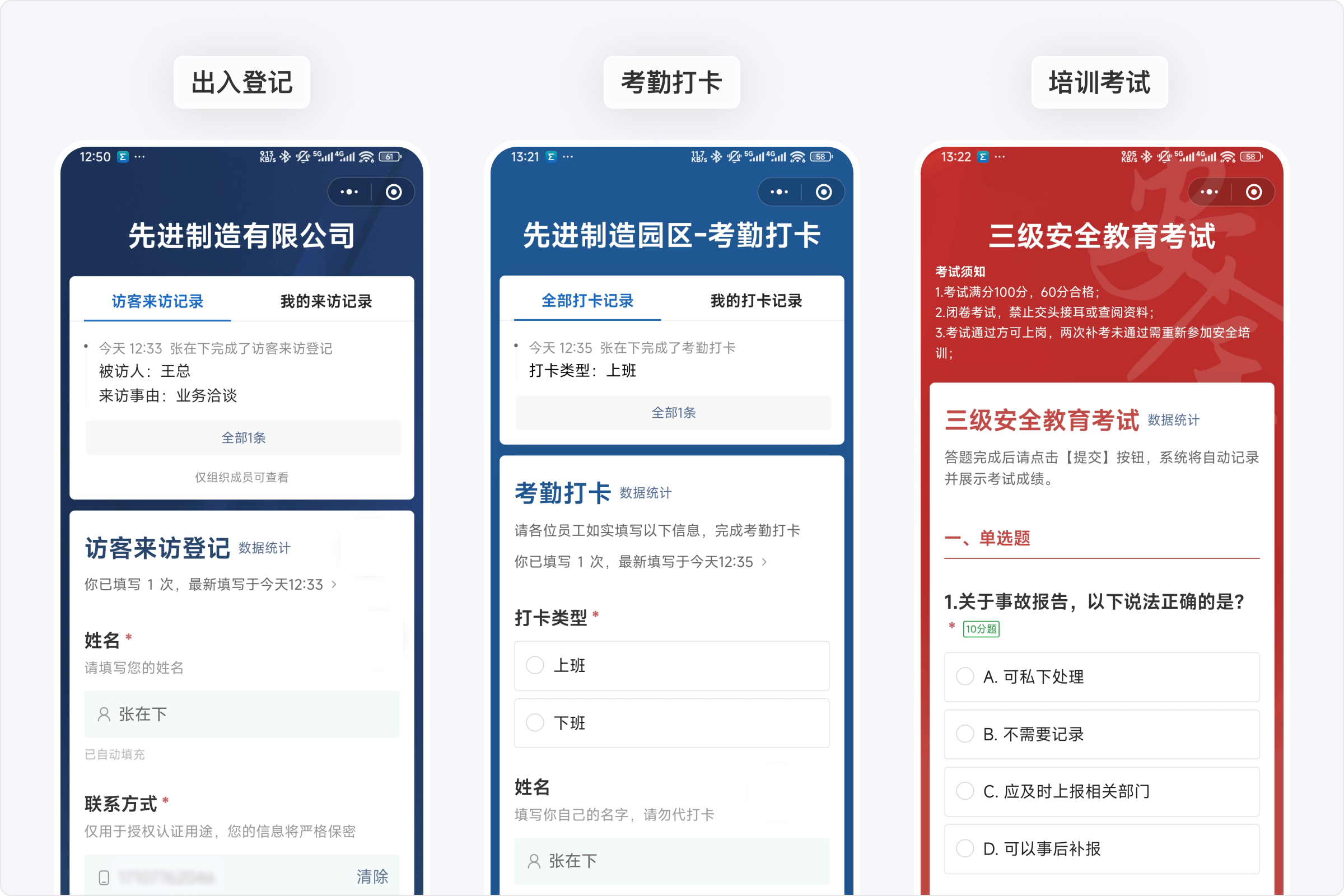

Standardized and Reliable Personnel Management

Simple and Traceable Personnel Access

Scan to register entry/exit information, reducing gatekeeper workload, ensuring complete records

Efficient, Anti-Cheating Attendance

Scan upon arrival to capture location, attendance data automatically summarized

More Convenient Training and Testing

Paperless exams support automatic grading, view correct answers after completion

Select Template to Generate Code

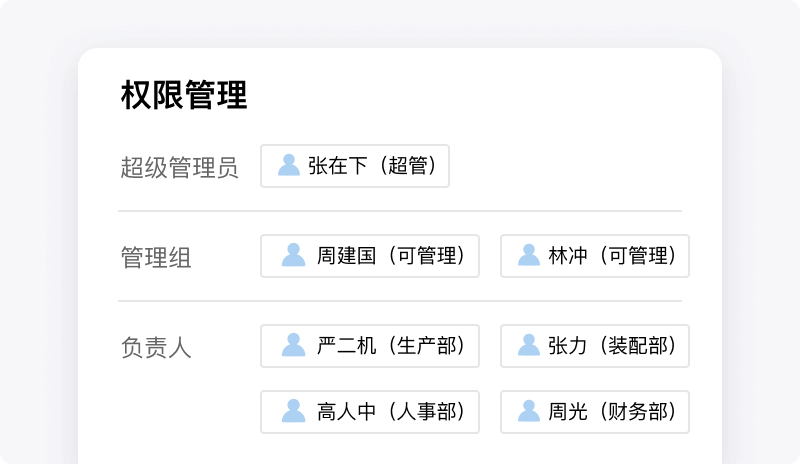

Specialized Roles, Clear Responsibilities

Different Roles for Different Members

Inspectors only inspect, maintenance personnel only repair, clear division of labor

Data Isolation by Department

Partition data by department and other dimensions, meeting audit standards

Select Template to Generate Code

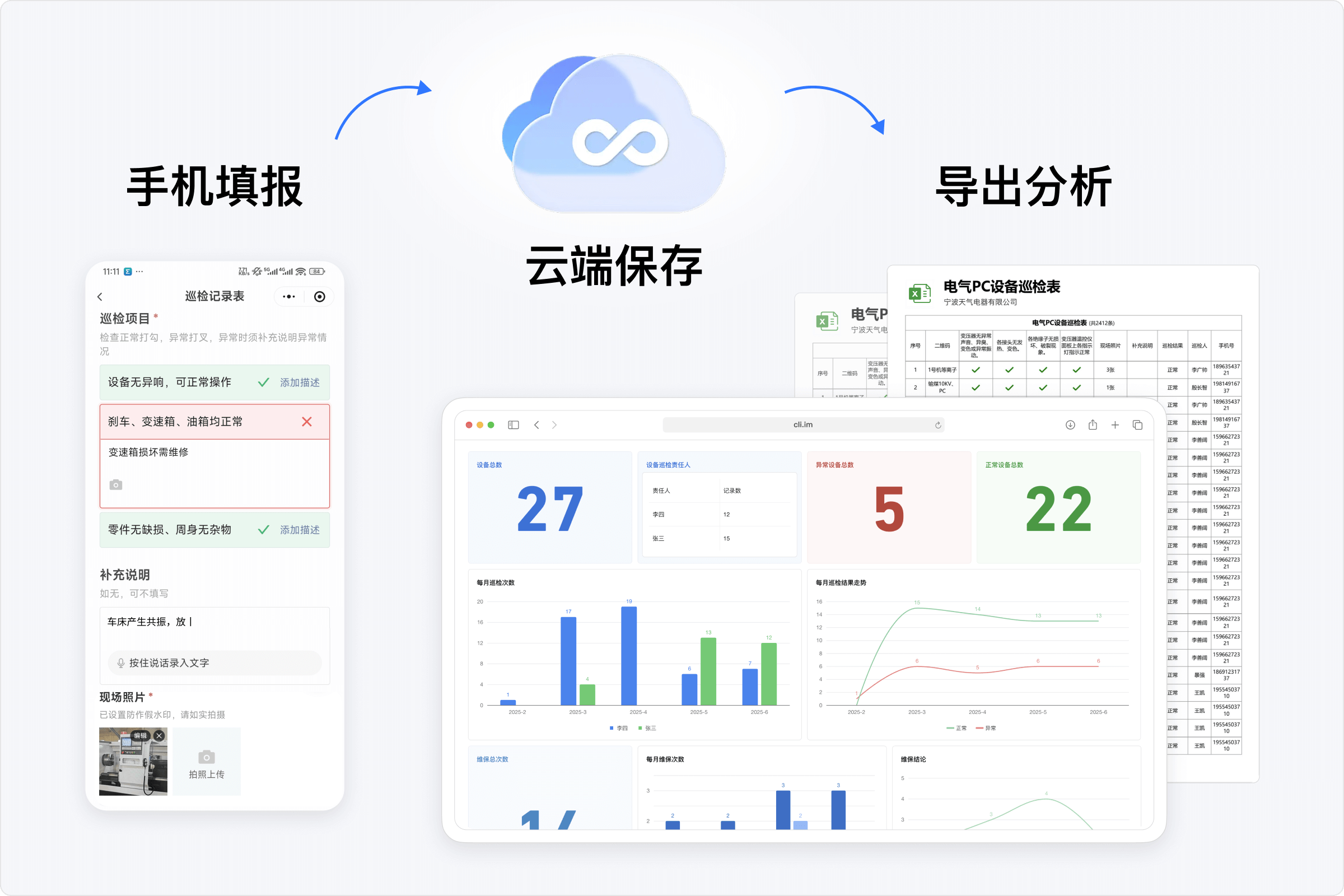

Fully Utilize Data to Enhance Management Level

Data Never Lost

Data permanently saved in the cloud, no longer scattered like paper forms

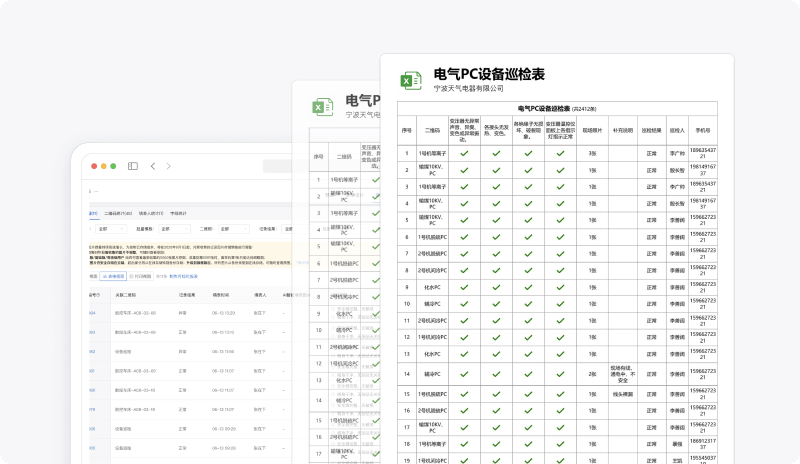

Export for Archiving Anytime

Support export to Excel spreadsheets, meeting existing management requirements

Visual Data Analysis

Integrate data into statistical analysis tools, saving time and effort on summaries and reports

Select Template to Generate Code

Free Version Meets Basic Needs

QR Codes are Long-Term Valid

Suitable for large-scale promotion, stable and scannable long-term

Unlimited Scan Times

All QR codes have no upper limit on scan counts

Unlimited Code Generation

No limit on the number of QR codes generated

Unlimited Content Uploads

Unlimited uploads of images, records, etc.

Paid Upgrade for More Efficient Team Management

Multi-User Management

Supports multiple users managing account content collaboratively, dividing labor, reducing admin burden

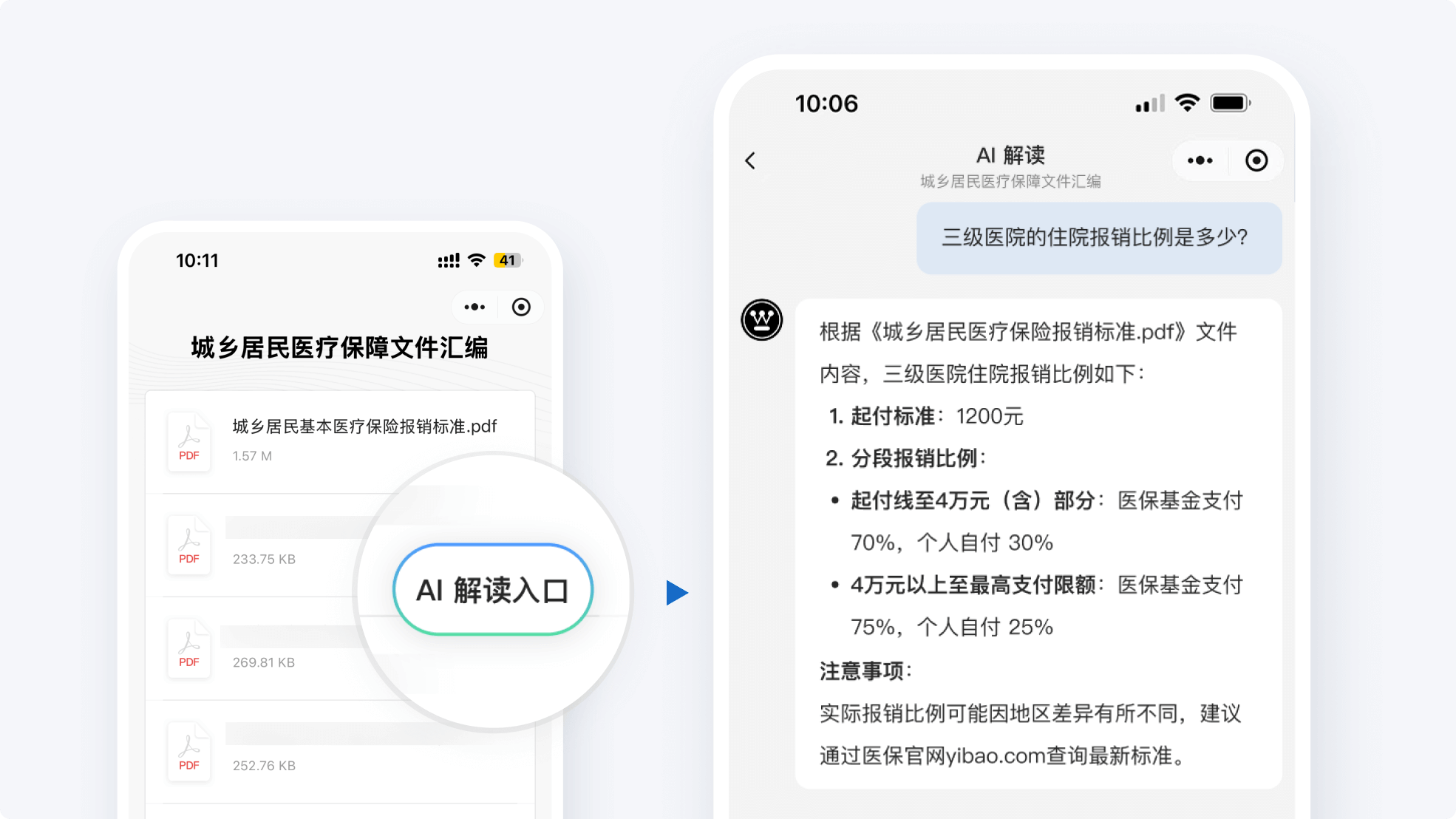

AI Interpretation

Upload equipment manuals, training materials; employees ask AI directly for issues

Unlimited Record Export Time Range

Export data from any time period anytime, meeting audit, year-end summary needs

Enterprise-Grade Security Capabilities

Utilizes advanced security gateways and domain protection mechanisms for comprehensive data security

Companies of All Sizes Use CaoLiao

Bull Group

Built an equipment monitoring and management system, achieving results comparable to professional MES systems at low cost.

Achieved 80% of MES System Functions

Lite Aviation Manufacturing

Built the company's TPM platform, quality supervision platform, hazard identification, and suggestion submission platform.

Hazard Rectification Efficiency Increased by 40%

Liuzhou Dongfeng Li'er Fansheng

5S provided simplified processes for shaping corporate image, reducing costs, ensuring safe production, and high standardization.

Significantly Improved On-site Management Effectiveness

Select Templates to Build Your QR Code System

The following templates come from real user practices, helping you quickly learn from industry peers and reduce setup costs

Equipment Inspection

Scan to conduct inspection tasks, upload on-site photos, enable anti-falsification, etc.

Use this template

Hazard Reporting

Scan to report hazard clues, achieve closed-loop management: report — rectify — accept

Use this template

Visitor Registration

Visitors scan to complete registration, administrators can view and export records in the workbench

Use this template

Safety Production Education

Scan to access materials, submit learning records, monitor learning status, implement training effectiveness

Use this template