QR Code-Based Fault Reporting System Boosts Repair Efficiency by 80% at This Factory

Original: https://cli.im/article/detail/2345

"Previously, when equipment broke down, workers had to make a phone call, fill out a form, and then find someone to handle it. Repairing a single piece of equipment could sometimes take an entire day. Now, with just a scan and a form fill, the maintenance team responds within 5 minutes." — Wang, Maintenance Supervisor, Jiangsu Zhongyu Electronic Equipment Factory

I. The Problem: Overly Complex Reporting Process, Inefficient Operations

Jiangsu Zhongyu is a manufacturing enterprise with 130 employees, specializing in the assembly and testing of power control equipment. The production line comprises nearly 100 large pieces of equipment that require regular inspections and timely repairs. However, in the first half of last year, their equipment maintenance management frequently "dropped the ball."

"The biggest pain point was that when equipment malfunctioned, on-site workers didn't know who to contact, and the repair process was unclear," Wang admitted. The previous method involved workers manually filling out paper repair request forms, which were then compiled by team leaders and submitted to the maintenance supervisor for approval before finally assigning a repair technician. This entire process often led to prolonged equipment downtime due to delays in information transmission.

More seriously, repair records were entirely handwritten, making subsequent tracing impossible and leaving no basis for analyzing which equipment had the highest failure rates. "We tried looking into some off-the-shelf work order systems, but most required development and purchasing hardware, which was too costly and complex," Wang recalled. During a casual exchange with industry peers, they learned about the CaoLiao QR Code platform, which allows building a reporting system with zero development. They decided to give it a try and began their reform.

II. Implementation: Scan-to-Report + Data Management, All-in-One Solution

The standout feature of CaoLiao QR Code is its ability to quickly build business systems by combining QR codes with forms, requiring no development or deployment. For manufacturers like Zhongyu without a dedicated IT team, there is virtually no learning curve.

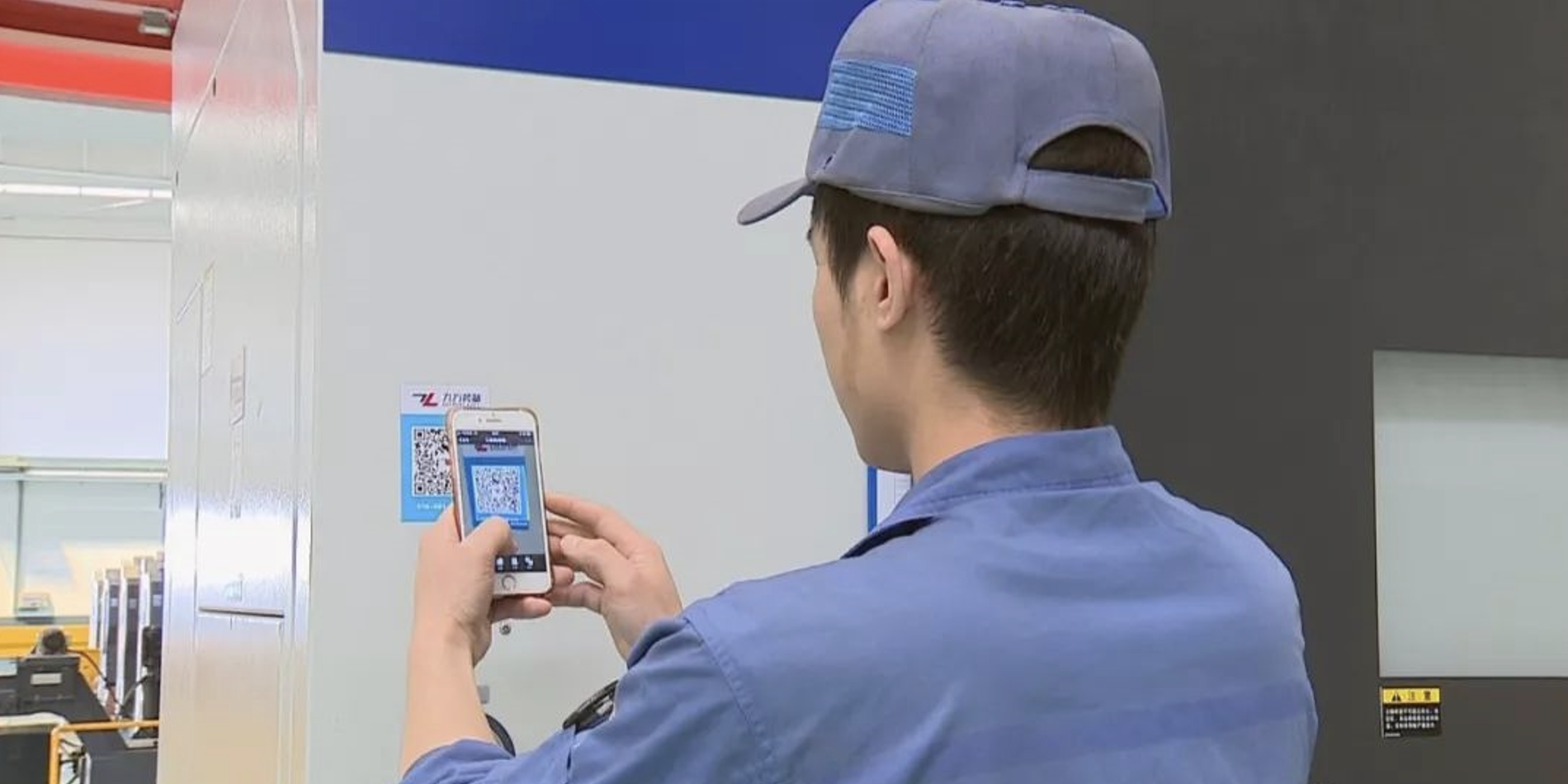

1. One QR Code per Device, Scan to Report

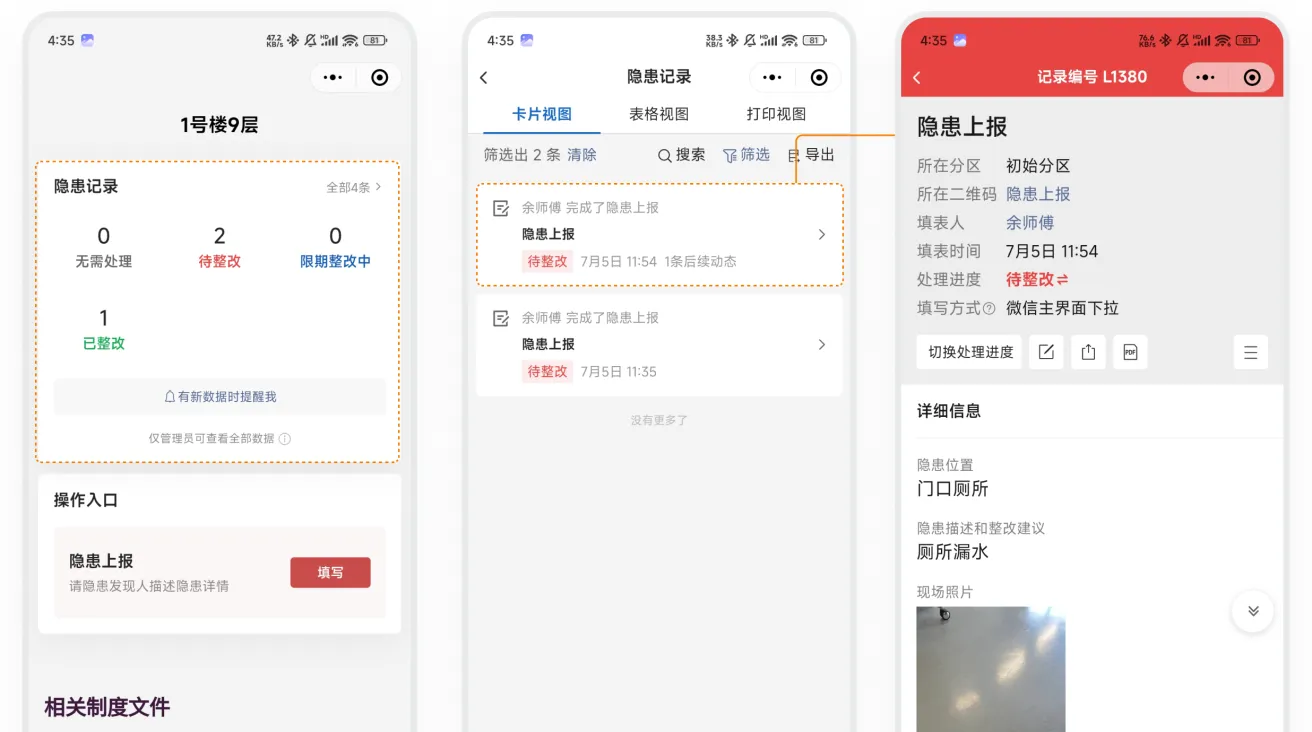

Each piece of equipment is labeled with a unique QR code. Workers simply take out their phones, scan the code with WeChat, and directly access the reporting page: the reporter's phone number and location are automatically recognized; after entering their name once, it doesn't need to be repeated; fault details (e.g., electrical control failure, motor jam, abnormal noise, oil leakage) can be entered via voice, which the system automatically converts to text; adding a photo of the scene and submitting completes the report.

The fields in the reporting form can all be configured in the CaoLiao backend without any technical knowledge. Business personnel can create the forms by simply dragging and dropping components. After some use, dropdown options can be added based on common fault types, making it quicker for workers to select the cause. "Now the workers are used to it. When they find a problem, they scan a code first, and maintenance sees it immediately," Wang said.

2. Automatic Assignment for Maintenance Staff, Quick Rectification

The CaoLiao QR Code platform supports notifications. Once a repair form is submitted, designated maintenance personnel immediately receive an alert in WeChat containing:

- Faulty equipment ID

- Fault description

- Fault location

- Reporter's name

- Photos of the fault

After completing the repair, maintenance staff directly fill in the rectification record below the original report entry, including details like repair time and success status, and update the repair status to "Rectified," documenting the entire process. They can also @mention inspectors for verification, creating a closed loop. The backend automatically aggregates all repair records, eliminating manual data entry and significantly reducing the management burden.

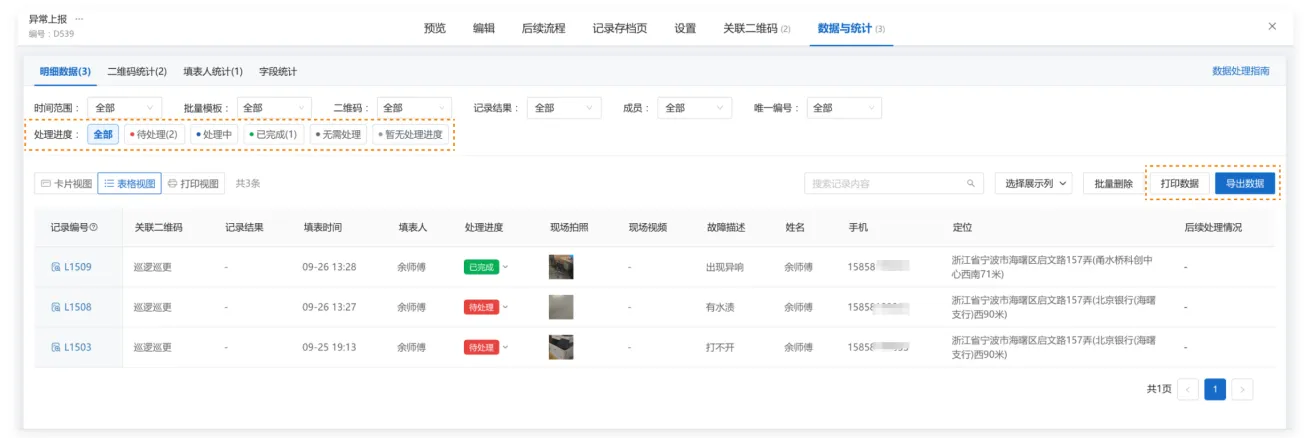

III. Data Visualization: Making Management Visible

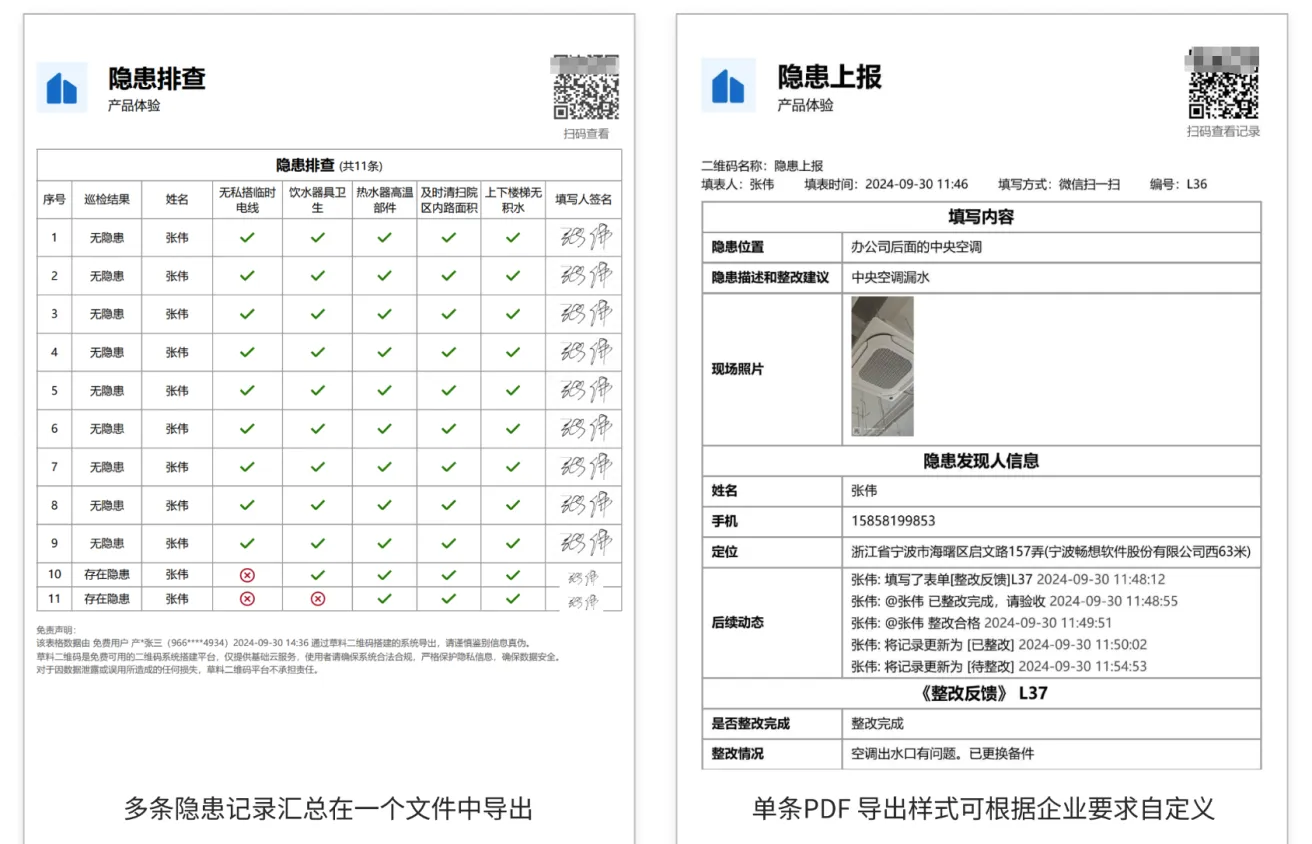

Previously, all reporting data was on paper forms, prone to loss and difficult to analyze. Now, all data is automatically aggregated in the CaoLiao backend. At the end of the month, Wang can export the reporting data to form clear tables and trend charts showing:

- Monthly number of reports

- Processing progress of faults

- Equipment IDs with the most reports

- Distribution of fault types

- Average response time

- Repair duration

This data gives equipment managers a "visible" view of maintenance trends for the first time. For equipment with frequent faults, they can schedule preventive maintenance in advance to avoid downtime losses. "We now hold a monthly equipment analysis meeting, relying entirely on the data records from CaoLiao," Wang said.

In addition to the computer backend, scanning the QR code also shows the number of faults and their processing progress, allowing quick identification of pending rectifications.

This data has archiving requirements. Using CaoLiao has standardized archival records. Fault reports and rectification records can be directly exported from the CaoLiao backend as PDF files for printing and archiving. It's clear who reported the fault and who performed the repair and when, eliminating concerns about inspections.

IV. Results: Doubled Efficiency, Reduced Costs

According to Zhongyu's internal statistics:

- Average response time for reports shortened from 1 hour to under 10 minutes

- Overall repair duration decreased by 35%

- The reporting process became transparent, significantly improving employee satisfaction

- The factory didn't need to purchase any hardware; using only CaoLiao QR Codes + printed codes made the implementation cost nearly zero

Furthermore, the features provided by CaoLiao QR Code are extensible. They plan to integrate inspection processes into the CaoLiao platform, forming a full-chain digital management system of "Inspection-Reporting-Repair," and create a data dashboard.

V. QR Codes: A New Solution for Repair Management in SMEs

This type of reporting system, combining QR codes + forms + WeChat notifications + data records, is naturally suited for small-scale digitalization in enterprises, especially the following types:

- Factories and property parks without dedicated IT teams seeking lightweight digital solutions

- Those with equipment reporting and maintenance processes but unclear workflows

- Those wishing to collect statistics but lacking management tools

The advantages of CaoLiao QR Code lie in:

- Simple operation: Use directly by scanning with WeChat

- Flexible configuration: All fields and processes are customizable

- No development needed: Business personnel can build the system by modifying templates or freely combining features

- Extremely low cost: Free to use; upgraded features are far cheaper than traditional systems

VI. Afterword

"Sometimes a problem isn't a technical issue but a matter of choosing the wrong tool," Wang reflected on the project implementation process. "We didn't change systems or buy equipment; we just used QR codes to link each step together, and efficiency improved." For manufacturing enterprises like Zhongyu, this simple and practical approach might just be the ideal starting point for digital transformation.