Shandong Port Group: Establishing Equipment Failure Archive QR Code Database, Launching New "Easy Inspection via Scan" Model

Original source: https://cli.im/article/detail/2420

Recently, a new highlight has been added to the equipment maintenance work at Rizhao Port No. 2 Company of Shandong Port Group. They have researched and designed an equipment failure archive QR code database, significantly improving the efficiency of equipment maintenance.

The machinery team at Rizhao Port No. 2 Company of Shandong Port owns hundreds of various types of mobile machinery, with different brands and purposes. Maintenance personnel found daily equipment inspections time-consuming and inefficient. To further improve the efficiency of routine inspections, the company's machinery team organized technicians, maintenance personnel, and key operators to form an innovation task force, researching and designing a QR code database for mobile machinery.

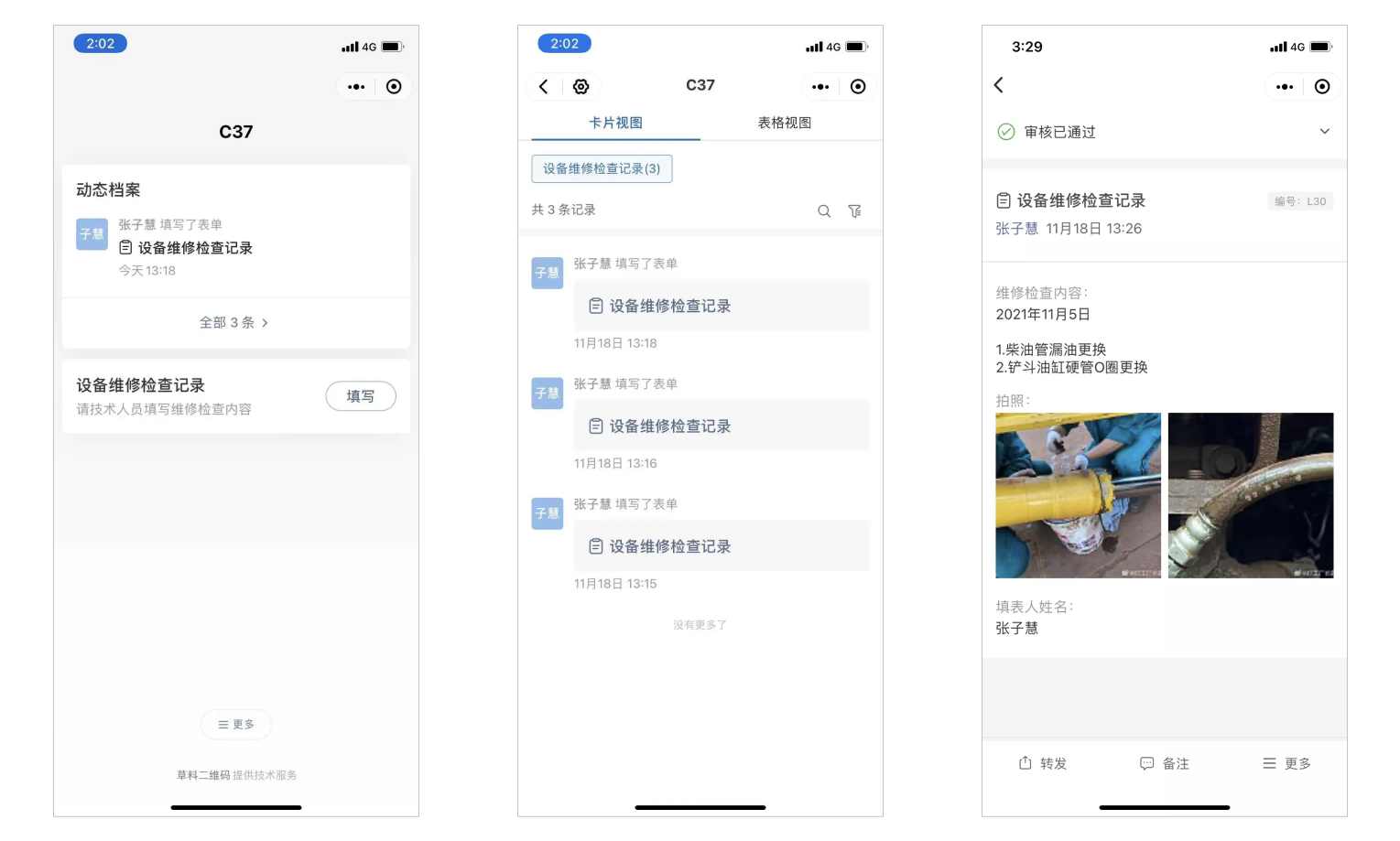

The team designed three QR codes for each piece of machinery: equipment ledger, operating instructions, and maintenance records, forming an equipment failure archive QR code database. The equipment ledger QR code links to basic factory information such as equipment parameters and main accessories, and is updated promptly with equipment maintenance. The operating instructions QR code links to detailed equipment usage and operation methods. The maintenance records QR code links to equipment maintenance records.

"Previously, it took over 60 minutes to fully inspect each piece of machinery. Now, by opening WeChat and scanning the QR code, we can immediately access the information we need, accurately determine equipment faults in the shortest time, and we've also hitched a ride on the high-tech bandwagon," said maintenance worker Guo Xiao excitedly.

The establishment of the equipment QR code database has enabled the sharing of equipment information archives. Through QR codes, operators and management personnel can conveniently and promptly understand the equipment's operation, maintenance, and inspection status. Management has become more scientific and standardized, further improving the efficiency of equipment maintenance and providing first-hand data to better utilize equipment performance and ensure production.

Originally published on the [Rizhao Port] WeChat public account, article link: [《Reform, Innovation, Strengthening the Port with Me ㊲ | Equipment Maintenance, Launching the New "Easy Inspection via Scan" Model》](https://mp.weixin.qq.com/s/XCOK4GhkxuDwIWrhdQvEBg "《Reform, Innovation, Strengthening the Port with Me ㊲ | Equipment Maintenance, Launching the New "Easy Inspection via Scan" Model》")