How Enterprises Can Achieve Compliance Management Under the Full-Chain Fire Protection Products Rectification Campaign

Original: https://cli.im/article/detail/2442

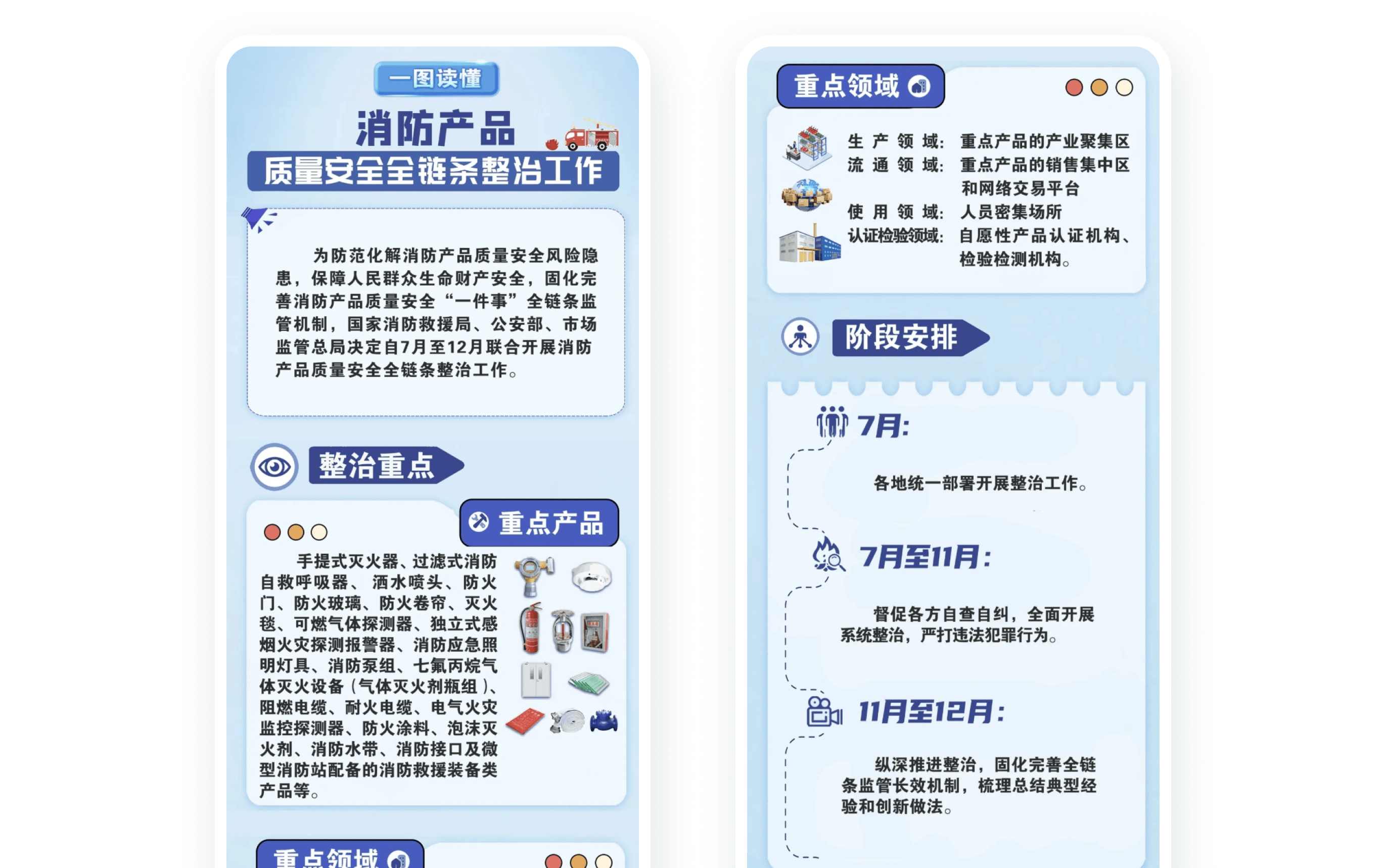

Starting July 2025, the National Fire and Rescue Administration, Ministry of Public Security, and State Administration for Market Regulation have jointly launched a nationwide rectification campaign targeting the quality and safety of fire protection products across the entire supply chain.

Key focuses include:

- Covered Products: Over 20 types of fire and rescue equipment, including fire extinguishers, fire doors, self-rescue breathing apparatus, and fire retardant coatings.

- Regulatory Scope: Comprehensive coverage of four key stages: production, distribution, usage, and certification/inspection.

- Objectives: Consolidate responsibilities, strengthen supervision, strictly penalize violations, optimize mechanisms, innovate methods, and establish long-term effectiveness.

In other words, this is not a mere "campaign-style enforcement" but aims to break down information barriers through structured management, truly achieving "traceable inspections, manageable control, and effective accountability."

1. The Core Compliance Challenge: Absence and Inaccessibility of Records

In the context of this full-chain rectification, enhancing record-keeping capabilities with lightweight tools is often more practical than implementing large, complex information systems.

In reality, many organizations still manage fire equipment records using Excel spreadsheets, paper certificates, bulletin boards, WeChat groups, or USB drives. The core issues are threefold:

- Discontinuous Records: Processes from receipt, installation, inspection, and maintenance to decommissioning lack unified identification, creating gaps and making it difficult to form a closed-loop.

- Records Not Linked to Physical Items: With numerous items of the same type, pinpointing a specific unit when issues arise is challenging.

- Records Inaccessible On-Site: Critical documents are often stored on office computers, making them unavailable for viewing or updating by frontline personnel in the field.

When records are missing, fragmented, or difficult to access on-site, even the most advanced systems struggle to solve the "last mile" problems of compliance and traceability.

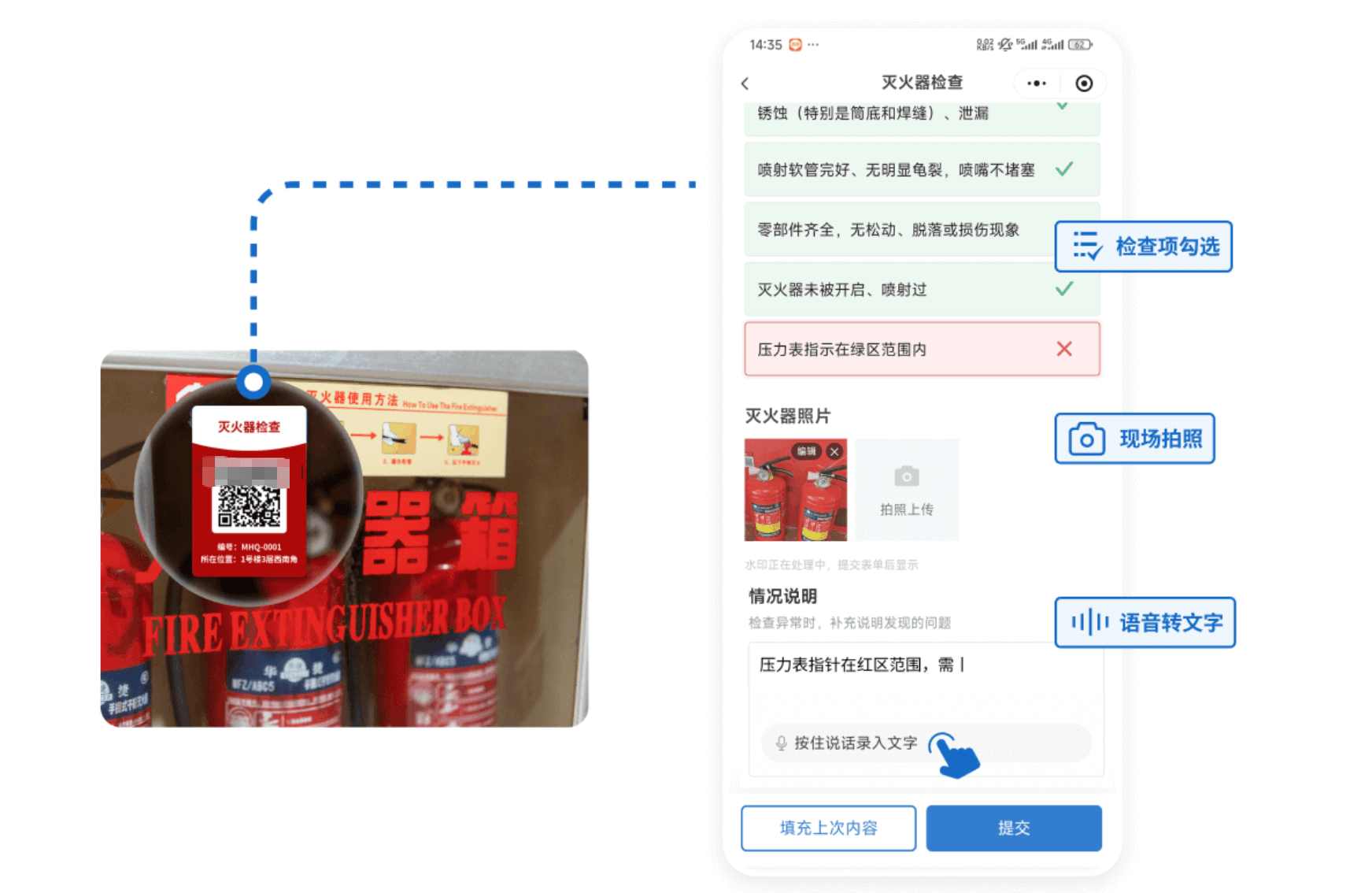

2. Low-Cost Solution: Using QR Codes to Create a "Digital File" for Each Item

Instead of first implementing a complex system, start by ensuring each piece of equipment has an information file that can be accessed anytime. The specific approach is as follows:

- One Code per Item: Create a unique QR code for items like fire extinguishers, fire doors, sprinkler heads, and emergency lights, linking them to basic data such as model, batch, production date, expiration date, and certification number.

- Centralized Information: Consolidate materials like certificates, inspection reports, maintenance contracts, and inspection photos/videos within a single QR code, allowing for instant verification by scanning on-site.

- Tracked Records: Use forms within the QR code to log activities like inspections, refills, replacements, and decommissioning, creating a timeline for easy traceability.

- Permission Control: Assign "view, fill, manage" permissions based on roles or positions. Non-managerial staff cannot view or operate data, ensuring security.

- Zero Training Cost: Frontline personnel only need to use WeChat to scan, view, and fill out forms. The process is clear, with a low learning curve.

This "information follows the equipment" approach is not only simple to operate but also prevents gaps due to staff changes or loss of records, truly enabling "the equipment to speak for itself."

3. Digital Management from Receipt to Decommissioning: The Full Lifecycle

Taking a fire extinguisher as an example, we can build an information file covering its entire lifecycle, ensuring clarity on "where it came from, where it is now, who manages it, what has been done to it, and when it expires":

- Receipt Registration: Generate QR codes in bulk, one for each extinguisher. In the backend, batch-link information like manufacturer, model, batch, factory certificate, inspection report, and upload photos of the acceptance slip.

- Storage and Installation: Affix the QR code label to the equipment. Scan the code to input the storage location, responsible department, and person in charge.

- Routine Inspections: Conduct periodic inspections by scanning the code, fill in the equipment status and any anomalies. The system automatically notifies the relevant responsible person to address issues.

- Maintenance and Replacement: Log maintenance and replacement records, upload photos, ensuring the maintenance process is traceable.

- Regulatory Spot Checks: Regularly export daily inspection and maintenance records for printing and archiving for routine checks. Regulatory authorities can also scan the code on-site to directly view the file.

- Expiration and Decommissioning: Mark the equipment status as decommissioned, record the reason, preventing refilling of old cylinders and illegal circulation.

4. How to Implement

Many organizations worry about "not understanding the technology" or "not being able to manage it." In fact, platforms like CaoLiao QR Code offer very lightweight solutions. The implementation process is as follows:

- Inventory and Preparation: Identify which products need files. It's recommended to start with a pilot on common items like fire extinguishers and fire hoses.

- Create Codes and Input Data: Use the templates provided by the CaoLiao QR Code platform to create QR codes, modify content as needed, and gradually upload existing documentation.

- Print and Affix: After generating the QR codes, print them using a standard printer or label maker. Affix the QR code labels to the equipment, and they are ready for use.

- Daily Use and Updates: Daily tasks include scanning to fill out forms, uploading inspection photos, marking anomalies, and updating data as needed.

The entire process requires no app installation or training. Anyone who can scan a code can use it. It's advisable to start with core data, moving "essential evidence" into the QR code first, then gradually adding detailed fields. Review the content's practicality every two weeks to avoid overloading the QR code or having data that is too coarse, preventing it from becoming "another complex system."

5. Summary

Compliance for fire protection products isn't just about "appearing problem-free"; it's about being able to "provide evidence proving it's truly compliant." While QR code digital files aren't a universal solution, they provide crucial support in the following areas:

- For Users: Visual management, clear responsibilities, self-certification of compliance.

- For Regulators: Increased efficiency in spot checks, rapid identification of problem sources.

- Regarding Violations: The tracking mechanism acts as a deterrent, enhancing the enforceability of accountability.

Compared to a one-time implementation of a heavy system, starting with the digital recording via "one code per item" is a more practical and faster-yielding path.

CaoLiao QR Code is not a万能 tool, but it makes much of the information that was previously "unmanaged, unsearchable, and unclear" clear and usable.

The rectification campaign is just the starting point. Digital record-keeping is the true long-term path for compliance building.