Gantry Crane Inspection

Establish electronic equipment records and inspection logs for construction machinery, special equipment. Scan QR codes to add daily inspection records. Accurately report abnormalities with photos, videos, etc., automatically send notifications to responsible persons to ensure safety. Example: Gantry Cranes.

Basic Information

- Monthly Installations: 3335

- Monthly Visits: 8770

- Original: https://cli.im/template/detail/56662325

Case Label Images

Usage Instructions

1. Problems Solved

Traditional inspection methods for loading/unloading and lifting equipment face the following issues:

- Manual recording is prone to errors and potential data falsification.

- Abnormal situations cannot be handled promptly.

- Paper-based data is difficult to aggregate and analyze.

To solve these problems, we use QR codes to replace paper checklists, generating a unique QR code for each piece of equipment, achieving "one code per device."

- Inspectors use WeChat to scan the code, view equipment information, conduct item-by-item checks, and take on-site photos to prevent missed inspections and falsified checks.

- When inspection results are abnormal, the system automatically notifies the maintenance responsible person for timely response and problem resolution.

- Inspection data is saved under the account, allowing managers to view, trace, and export data for analysis anytime via the workbench.

This template is suitable for gantry cranes, tower cranes, cranes, forklifts, and other loading/unloading and lifting equipment. Each device corresponds to one QR code, made into a label attached to the equipment. Scanning the code initiates inspection and maintenance recording.

2. Equipment Record Information, Viewable via Scan

One device, one code. Scan to view equipment information.

- View equipment parameters and documents: After scanning, inspectors can see the device's basic information.

- Change equipment operational status: Update the operational status promptly based on the equipment's condition.

- Fill out inspection forms: Record inspection details item by item.

- View inspection data for this device: Understand historical inspection records and issues.

Note: If the device has other items requiring recording, more forms can be added. One QR code can be associated with multiple business forms, such as: checklist, fault repair form, equipment startup/shutdown log, etc.

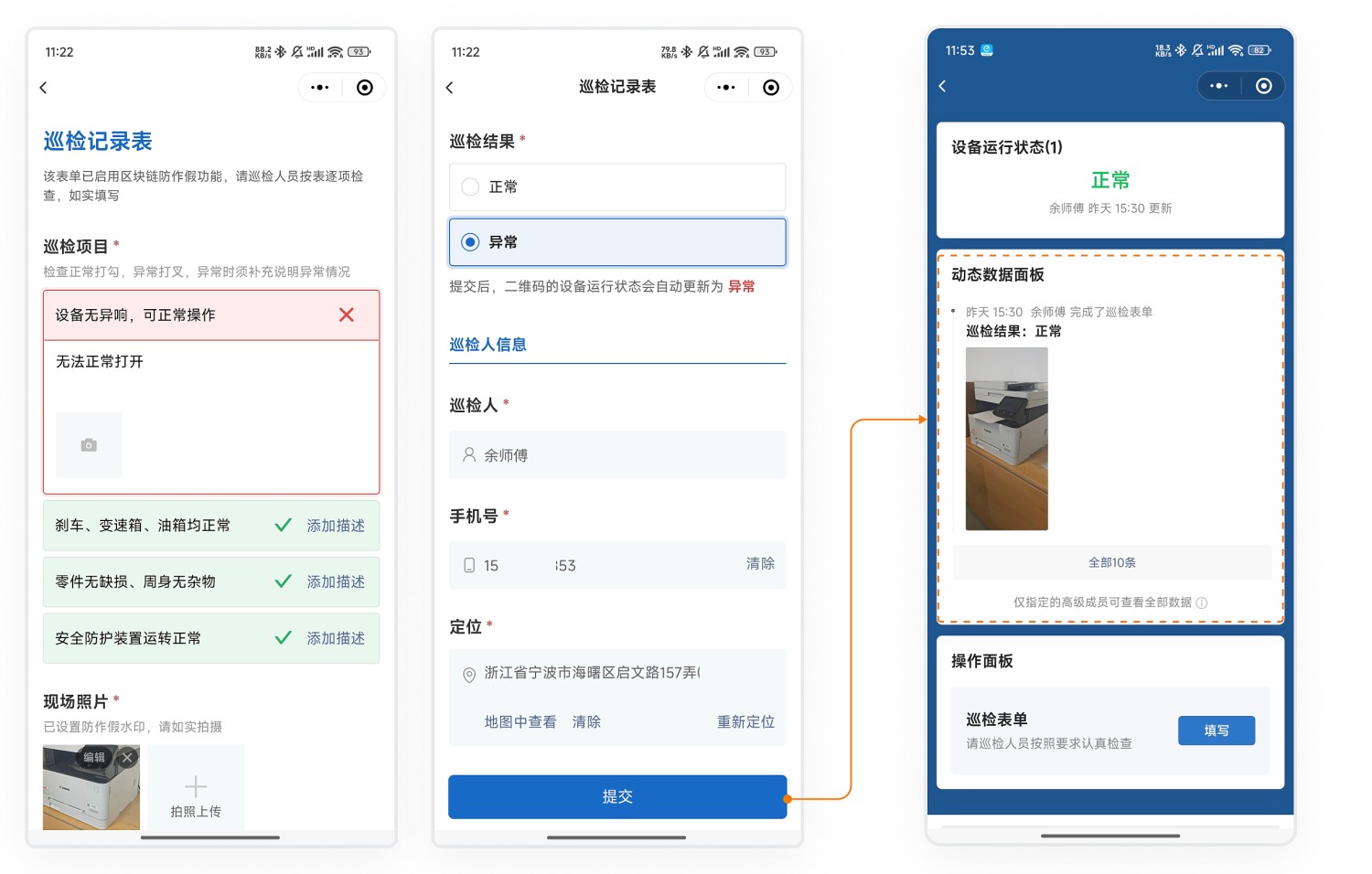

3. WeChat Scan to Fill Out, Record Inspection Status

Inspectors use WeChat to scan the code and record the inspection status according to the set inspection form specifications, checking item by item. To prevent falsified inspections, we provide the following features:

- Only allow on-site photos: Ensures photo authenticity.

- Photo watermark: Automatically adds time, location, and other information to photos.

- Location function: Records the inspection location.

- Blockchain notarization: Protects data authenticity and prevents tampering.

Collected inspection data is displayed on the dynamic data panel, viewable by scanning the code. View Form Features

4. Handling Abnormal Situations, Recording Rectification Content

When inspection results are abnormal, the system automatically notifies maintenance personnel via WeChat.

- Maintenance personnel, upon receiving the abnormal record, follow up promptly and completely record the entire maintenance and rectification process.

- Acceptance personnel perform acceptance confirmation to ensure the issue is resolved.

The entire process is recorded, facilitating later analysis and improvement. Learn about Scenario Description

5. Regular Inspections, Pre-Expiry Reminders

As needed, create inspection and maintenance plans, e.g., monthly maintenance.

- Inspectors can view inspection history and the next inspection time after scanning the code.

- Administrators can view plan reports on the mobile workbench to understand completion status.

- Pre-expiry reminders: Before an inspection is due, the system reminds administrators via WeChat, listing equipment nearing expiry for timely maintenance scheduling.

6. Data Management

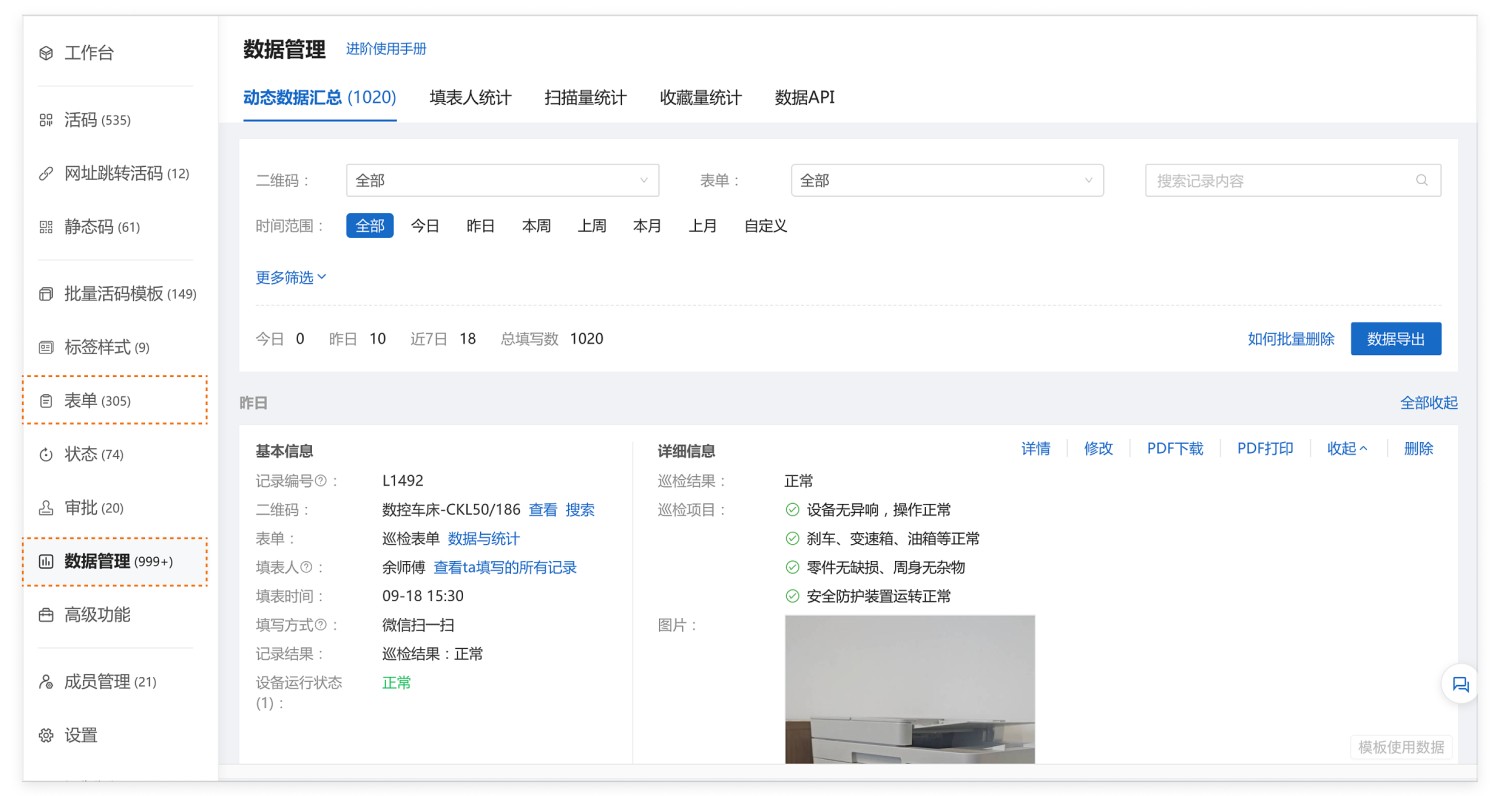

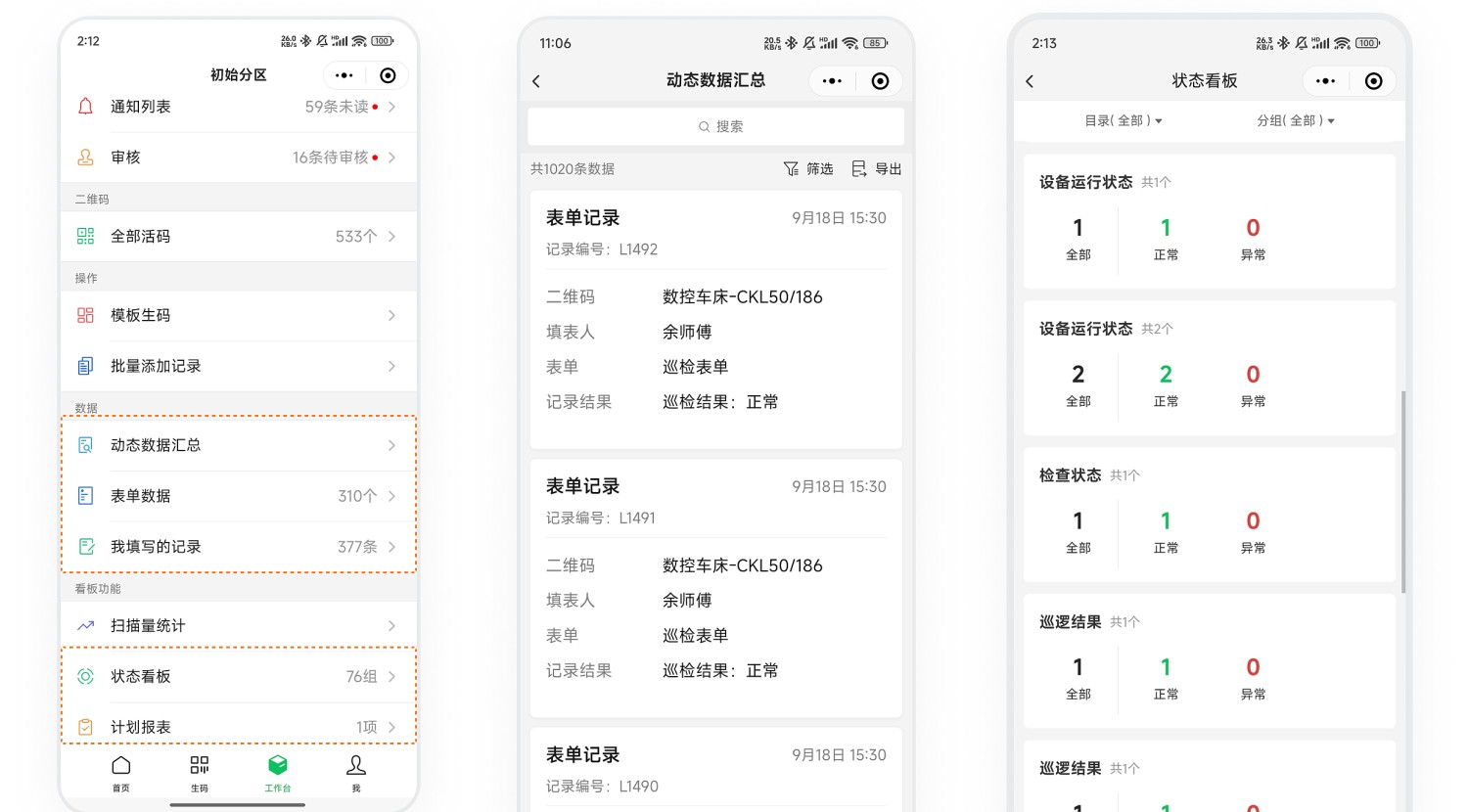

6.1 Data Viewing

All submitted form data is saved under your account. Administrators can view inspection status anytime via:

Desktop Workbench

Mobile WeChat Mini Program Workbench

6.2 Data Statistics and Export

On the form's "Data & Statistics" page, you can view all collected detailed data and view statistics based on associated QR codes, submitters, fields, etc. View Details

Data can be:

- Exported as Excel files for secondary processing, statistical analysis, and reporting locally.

- Downloaded as PDF files, detailing single records or summarizing multiple records, for easy printing and sharing.

6.3 Data API

We provide Data API functionality, supporting:

- Automatically push inspection data to WeCom, DingTalk, Feishu group chats, etc., for real-time sharing and communication, improving efficiency.

- Create data statistics dashboards: Use with visualization tools to intuitively understand inspection status.

7. Frequently Asked Questions

7.1 Which operations can have permissions set?

Answer: You can set permissions for specific personnel for the following operations:

- Viewing QR codes

- Changing equipment status

- Filling out inspection forms

- Viewing data on the QR code page

7.2 How to manage many device types and large quantities?

Answer:

- Advanced members: Versions above Advanced offer advanced member slots. You can set other management personnel as advanced members, granting them administrator permissions. They can log into the workbench to assist with QR code generation, data viewing, and export. Learn about Advanced Members

- Partition management: Create multiple partitions to manage different types of equipment and data separately. Advanced members can be set as partition managers for independent management and control permissions. View Setup Tutorial

7.3 How can administrators see inspection results for all equipment?

Answer: Equipment status is displayed on the QR code page and automatically updates based on inspection records (e.g., changes from "Normal" to "Abnormal").

Administrators can view the distribution of equipment status (Normal/Abnormal) in the status list on the mobile or desktop workbench to understand inspection results. View Details

7.4 Is there a complete manual for setting up equipment inspection scenarios?

Answer: Yes, please click to view the detailed illustrated tutorial