Why Do 90% of Digital Transformation Initiatives Fail at the Start for SMEs?

Original: https://cli.im/article/detail/2357

In the daily management of many enterprises, "digital transformation" is no longer a new term, but projects that are smoothly advanced and effectively implemented are rare. Especially for small and medium-sized enterprises (SMEs), digital transformation often stalls at the very first step: not knowing which tools to use or where to start.

"High development costs, long implementation cycles, and low employee adoption" have become the three major obstacles hindering SMEs from advancing digitalization. Faced with custom development projects that often cost hundreds of thousands or even millions, many enterprises hesitate. Meanwhile, general-purpose SaaS systems are often overly complex and do not align with actual business processes, ultimately leading to abandonment.

However, this does not mean that SMEs cannot take the first step in digital transformation. Low-cost, rapidly deployable, no-code platforms with no development barriers are emerging as a new solution. Among them, no-code platforms centered around QR codes have been validated as a feasible approach in multiple scenarios.

Why Do Digital Transformation Projects Struggle to Take Off in SMEs?

Limited Budgets, Unable to Bear High Development Costs

SMEs commonly face cash flow constraints and are extremely cautious about investing excessive costs in projects with "no short-term returns." Custom system development is not only expensive but also involves hidden costs such as dedicated maintenance and server deployment.

Long Project Cycles, Slow Response to Business Changes

From requirements analysis and prototype design to development and launch, projects often take months or even over half a year. Once business processes change, the system requires modifications, leading to slow responses and difficult updates.

Complex Operations, Frontline Employees Struggle to Use

Many traditional software tools are designed with IT professionals in mind, making them difficult for frontline employees to adopt. This results in situations like "systems going unused," "preferring Excel for speed," and "underutilization of features" recurring frequently.

"QR Codes + No-Code Platforms": A Digital Approach Suitable for SMEs

For enterprise managers genuinely wanting to drive digital transformation, a practical question is: Is there a solution that doesn't rely on a development team, can be trialed within three days, and requires no employee training?

The answer is yes. Using QR codes as entry points for business management, combined with no-code tools to build lightweight forms, information displays, and management interfaces, can complete a basic digital closed loop. This approach can solve 80% of the business problems encountered during SME digital transformation.

This method may seem simple but effectively addresses inefficiencies in many traditional scenarios. It is already widely used across various industries such as manufacturing, property management, schools, and public institutions. For example:

- Employee safety training check-ins via QR code scans, with data automatically recorded in the backend.

- Codes attached to equipment; one QR code per device allows scanning to view device information, maintenance records, and submit repair requests.

- Inspection personnel scanning codes to report potential hazards, with automatic notifications sent to responsible persons.

- Customers scanning codes to register information, with backend aggregation generating customer ledgers.

- Warehouse goods labeled with codes, scanning to register inbound/outbound quantities, automatically tracking inventory.

- Products featuring QR codes displaying parameters, selling points, and operational videos for customer access.

Implementing these functionalities requires no coding—just combining modules provided by the platform.

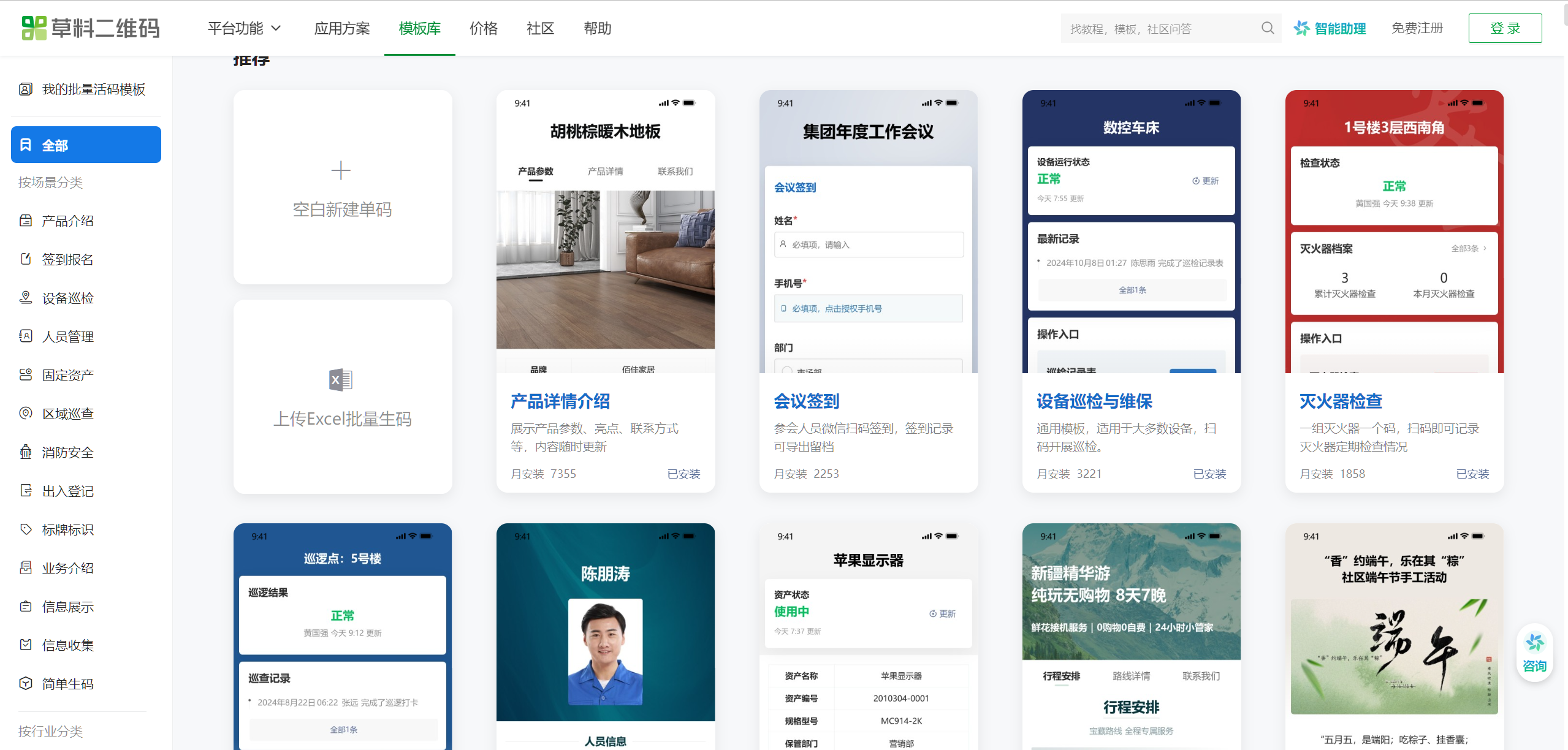

Core Capabilities of a QR Code No-Code Platform: An Example

Taking the representative CaoLiao QR Code no-code platform as an example, its main capabilities include:

- One Object, One Code Management: Generate unique QR codes for each device/item/person as a "digital ID," enabling subsequent scanning to view, update, or add records.

- Electronic Forms: Quickly build data collection forms (e.g., equipment inspection, repair requests, asset tracking, meeting check-ins) by combining different form fields.

- Permission Control: Set visible content ranges for employees scanning codes to ensure data security.

- Data Aggregation and Export: Automatically record all scan data in the backend, supporting categorized queries and report exports.

- WeChat Scan & Use, No Registration Required: Form filling via scanning can be completed within WeChat, requiring no app downloads or user registration.

- Deep Integration with WeChat Ecosystem: Embeddable in Official Account menus, WeChat notifications, synchronizable with WeCom, etc.

- Free to Use: Basic features are free, with no limits on QR code generation or data collection quantities. QR codes remain valid long-term, meeting most user needs at no cost.

By combining these modules, enterprises can build their own lightweight management systems like "building blocks," without relying on IT or outsourcing.

Cost and Efficiency Comparison

| Dimension | Custom Development | Traditional SaaS | CaoLiao QR Code |

|---|---|---|---|

| Launch Cycle | 3-6 months | 2-4 weeks | 0.5-3 days |

| Initial Investment | ¥50k - ¥500k | ¥10k - ¥30k | ¥0 |

| Usability Barrier | High, requires training | Medium, relies on support | Low, scan to use |

| Flexibility | Low, changes require development | Medium, depends on feature support | High, updatable anytime |

| Cost Control | Poor, many change fees | Moderate, package-based billing | High, upgrade as needed, many free features |

Usage Example

Assume a small machinery manufacturer with 50 pieces of equipment needs to solve management issues for equipment documentation, daily inspections, and fault reporting.

Using the CaoLiao QR Code no-code platform, they can quickly set up an equipment inspection QR code management system as follows:

- Input basic equipment information: model, location, responsible person, documentation, photos, etc.

- Use the provided equipment inspection template, modify content based on actual needs, edit forms, or add more forms (e.g., inspection records, maintenance records).

- Configure business processes: Enable inspection anti-fraud features, fault reporting reminders, etc.

- Input basic equipment info, use the bulk QR codes generation function to create one free QR code per device, print and attach them.

- Inspection personnel scan codes to report status; backend aggregates data, generates ledgers, filterable and exportable by device, time, fault type, etc.

The entire process requires no development and can be configured by business personnel in 1-3 hours. Employees only need to scan codes via WeChat, significantly lowering the usage barrier.

Final Thoughts

When taking the first step in digital transformation, SMEs should not blindly pursue "large and comprehensive" systems. Instead, combinations of "small and agile" tools can digitize key processes at the lowest cost, avoiding resource waste.

QR codes, as tools everyone can and knows how to scan, efficiently support data collection, simple business workflows, and data statistics. Compared to traditional development methods, this approach is lighter, faster, cheaper, and better aligns with the practical needs of SMEs in the early stages of transformation.

If you are preparing to start your enterprise's digital management, consider beginning with low-barrier, high-efficiency tools like CaoLiao QR Code. Proceed step by step, advancing steadily.