Production Line Product Coding Solutions

Original: https://cli.im/article/detail/2009

Product coding is widely used in industries such as food & fresh produce/pharmaceuticals/seeds & pesticides/automotive parts for traceability tracking, after-sales maintenance, promotional campaigns, and information anti-counterfeiting. The main challenges in product coding are the large volumes, high labor costs, and difficulty in achieving standardized processing.

- Traditional Coding Solutions: Require manual coding operations, resulting in higher costs, lower efficiency, and a higher error rate.

- Efficient Inkjet Coding Solutions: Effectively improve product coding efficiency. The cost per product can be as low as 0.001 RMB. It's a one-time investment for long-term use. The entire process is automated, offering high speed and efficiency, saving significant manpower, and effectively standardizing coding quality. Small and medium-sized enterprises can also deploy it simply and quickly.

Implementation Solutions

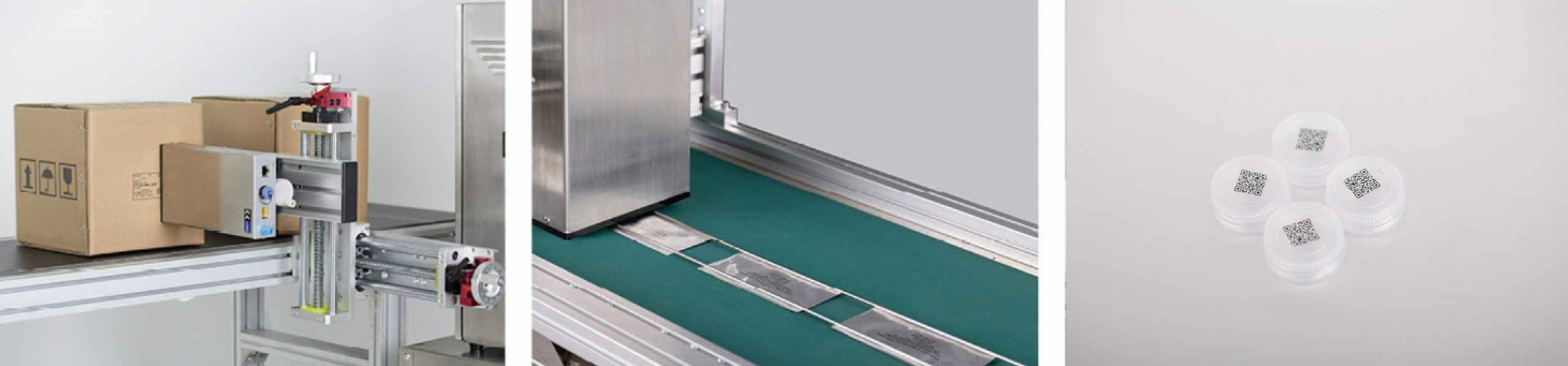

CaoLiao collaborates with professional equipment manufacturers to provide users with solutions for high-volume product coding (one code per item / one code per SKU), helping you achieve rapid implementation at low cost. We offer a complete set of equipment setup and implementation usage plans. After generating QR codes in bulk on CaoLiao, you can directly export the backend data and import it into the device software for batch layout and coding. The operation is simple and fast.

We provide various coding solutions suitable for different materials, processes, and scenarios, along with guidance and training from professional technical personnel. We support integration into production lines to enhance coding efficiency. If you have requirements for high-volume product coding, please Contact Us.

Laser Marking Solutions

Utilizes lasers to engrave content onto the surface of items, enabling permanent marking. It has a wider application range and can code on complex product surfaces. It is more suitable for small and medium-sized enterprises due to greater flexibility.

- Applicable Scenarios: Small household appliances, hardware products, automotive and motorcycle parts, sanitary ware, processing consumables, etc. More suitable for SMEs.

- Coding Speed: 2-3 seconds per mark. Specific speed varies depending on the printing area. Can mark 3000+ QR codes per day.

- Implementation Cost: Full set of equipment costs 10,000 - 30,000 RMB, usable for 5-10 years. No consumables required.

- Advantages: Capable of permanent marking, low cost, suitable for SMEs.

//blogcdnimg.clewm.net/2022/10/video9_16669348945585.mp4

Laser marking machines can be categorized into two types based on their operation mode: Static Laser Marking Machines and Flying Laser Marking Machines.

- Static Laser Marking Machine: Suitable for small batch product coding. Comes with a workbench, requires manual placement for coding.

- Flying Laser Marking Machine: Can be integrated into production lines for fully automated operation. The detection device automatically codes upon detecting a product, requiring no manual intervention. Costs approximately 1000-2000 RMB more than static laser marking machines.

Laser marking machines can be categorized into three types: Carbon Dioxide (CO2), Fiber, and UV, suitable for different materials like metals, plastics, paper, and polymer materials. Selection can be made based on product material and requirements.

- CO2 Laser Marking Machine: Suitable for marking most non-metallic materials and a small number of metallic materials. Price: 15,000 - 20,000 RMB.

- Fiber Laser Marking Machine: Suitable for marking most metallic materials. Price: 10,000 - 15,000 RMB.

- UV Laser Marking Machine: Can mark on materials sensitive to heat. More expensive, price: 20,000 - 30,000 RMB.

UV Inkjet Coding Solutions

Utilizes non-contact inkjet printers to code on product surfaces. Supports production line coding. The machine automatically starts coding when the sensor detects a product on the conveyor belt, with a fixed printing position. Initial setup requires adjusting parameters like coding height, conveyor speed, and ink density, which takes considerable time. Once configured, it can be used long-term.

- Applicable Scenarios: High-volume coding for food packaging bags, seed packaging bags, medicine boxes, cartons, and various packaging materials.

- Coding Speed: A single machine can code 200,000+ product packages per day.

- Implementation Cost: Full set of equipment costs 40,000 - 60,000 RMB. Cost per code can be as low as 0.001 RMB. Usable for 5-10 years. Ink cost is 1300-1800 RMB/L, capable of printing 3-5 million single codes.

- Advantages: No manual operation required, high speed and efficiency, different inks can be selected for different materials.

//blogcdnimg.clewm.net/2022/10/核酸检测条自动喷码2_Trim_16669347155002.mp4

Data and Layout

The coding equipment comes with built-in professional layout software that supports exporting data from CaoLiao. This data can be imported into the device software for custom label style layout, achieving data integration. Supports multiple methods for bulk QR code generation and bulk coding, such as USB drive, database, and offline generation, to enhance productivity.

USB Drive Import

After generating QR codes in bulk on CaoLiao, you can export the data as an Excel spreadsheet, copy it to a USB drive, and import it into the device to read the data for batch layout. Saved templates can be reused, eliminating the need for repeated setup.

Database Integration

The equipment supports API database integration, directly reading data from the official CaoLiao database via network interfaces to enable online data retrieval for layout and coding.

Mobile Bluetooth Transfer

After generating codes via the mobile Mini Program, data can be input to the device host via Bluetooth, directly reusing templates for coding. This is more suitable for production line operators, allowing on-site operation without a computer. (Feature in planning)

Offline Code Generation

Input the product batch number range in the mobile Mini Program to generate codes. After generation, device setup instructions are automatically created. Follow these instructions on the device, input the corresponding data and increment rules to generate codes in bulk. The QR code data synchronizes with CaoLiao, achieving offline data integration. (Feature in planning)

Contact Us

CaoLiao can assist you in designing coding solutions and provide installation and operation training. If you have requirements for high-volume product coding, please contact our staff. Provide your printing requirements and relevant samples. We will conduct proofing tests for you and recommend suitable implementation solutions based on the material.