Shengyiong Energy Calcium Carbide Plant: "One Machine, One Code" Facilitates New Inspection Paradigm

Original: https://cli.im/article/detail/2227

Equipment inspection is a crucial process for effectively ensuring the safety and stable operation of equipment. To save inspection time and enhance efficiency, the Lanchar Workshop of Shengyiong Energy Calcium Carbide Plant recently adopted a technology-enabled and smart inspection model. They created exclusive "identity codes" for key on-site equipment and facilities, utilizing "one machine, one code" to achieve digitalized, intelligent, and visual inspections.

Under the strategic deployment of the Calcium Carbide Plant to drive safety production through technology, the Lanchar Workshop leveraged intelligent and informational platforms to explore equipment inspection management practices within the realm of smart operations platforms. After technical team efforts, the workshop decided to implement equipment management "identity codes," using "one machine, one code" to promote visual and standardized inspections.

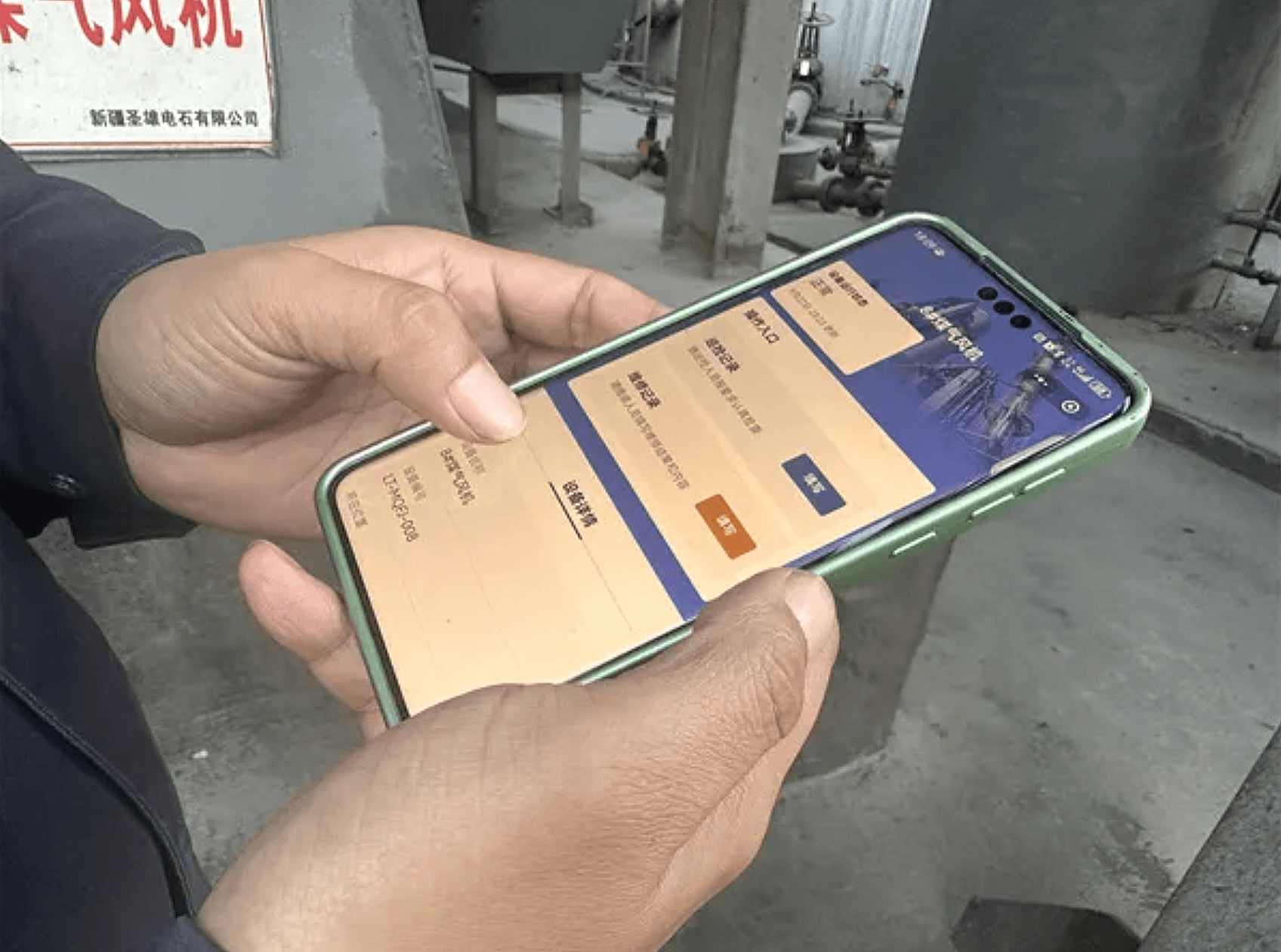

Inspectors regularly visit designated locations and simply scan the QR code on the equipment with their mobile phones to quickly access basic equipment information. They can then fill in inspection results, equipment operating parameters, maintenance records, inspector details, and relevant maintenance personnel information in real-time.

Simultaneously, the inspection data is automatically uploaded to the management end, enabling real-time data synchronization. This facilitates backend data analysis and monitoring by managers. If any abnormalities are detected, maintenance personnel can be immediately notified to address the "potential hazard point." Once resolved, on-site photos can be uploaded promptly, inspection results updated, and equipment hazard alerts cleared. This allows management to remotely oversee and precisely control equipment anytime and anywhere, enhancing safety and stability in workshop management.

"With this QR code, I have more confidence in managing our team. We no longer worry about missing items or errors from manual entry, the heavy workload of organizing and analyzing information, or data accuracy issues. It significantly reduces the burden of equipment inspection management," said team leader Zhang Guoshou confidently.

Wang Zheng, Deputy Senior Engineer of Shengyiong Energy, Deputy Plant Manager of the Calcium Carbide Plant, and Safety Director, stated that the Lanchar Workshop's "scan-to-inspect" approach has transformed the traditional inspection model, standardized the inspection process, and improved efficiency. It achieves closed-loop management from hazard detection and reporting by inspectors to assignment, maintenance, and resolution, effectively preventing hazards and accidents, thereby ensuring equipment operational safety.

Original reposted from WeChat Public Account: Zhongtai Zero Distance 《[Technology Empowerment | "One Machine, One Code" Facilitates New Inspection Paradigm: Lanchar Workshop of Shengyiong Energy Calcium Carbide Plant Achieves Tech-Enabled Equipment Inspection](https://mp.weixin.qq.com/s/O9jMPsMKvL_8G3A6tIl2-w "Technology Empowerment | "One Machine, One Code" Facilitates New Inspection Paradigm: Lanchar Workshop of Shengyiong Energy Calcium Carbide Plant Achieves Tech-Enabled Equipment Inspection")》