How CaoLiao QR Codes Empower Digital Equipment Management at Better

Original: https://cli.im/article/detail/2235

In today's rapidly evolving manufacturing landscape, equipment management efficiency directly impacts a company's productivity and competitiveness. Our company also faced numerous challenges within our equipment management processes.

Now, in an era where scanning QR codes to pay for groceries and shopping is commonplace, our company has kept pace with the times by implementing a QR code system to manage business processes related to quality, equipment, safety, projects, and improvements.

This article will focus on "CaoLiao QR Codes," sharing how they have optimized Better's equipment management processes, enhancing maintenance efficiency and equipment operational quality.

01 Implementation Planning

Within "CaoLiao QR Codes," we first built forms in the workbench to plan functional modules for the equipment management module, including inspection, maintenance, repair requests, and data dashboards.

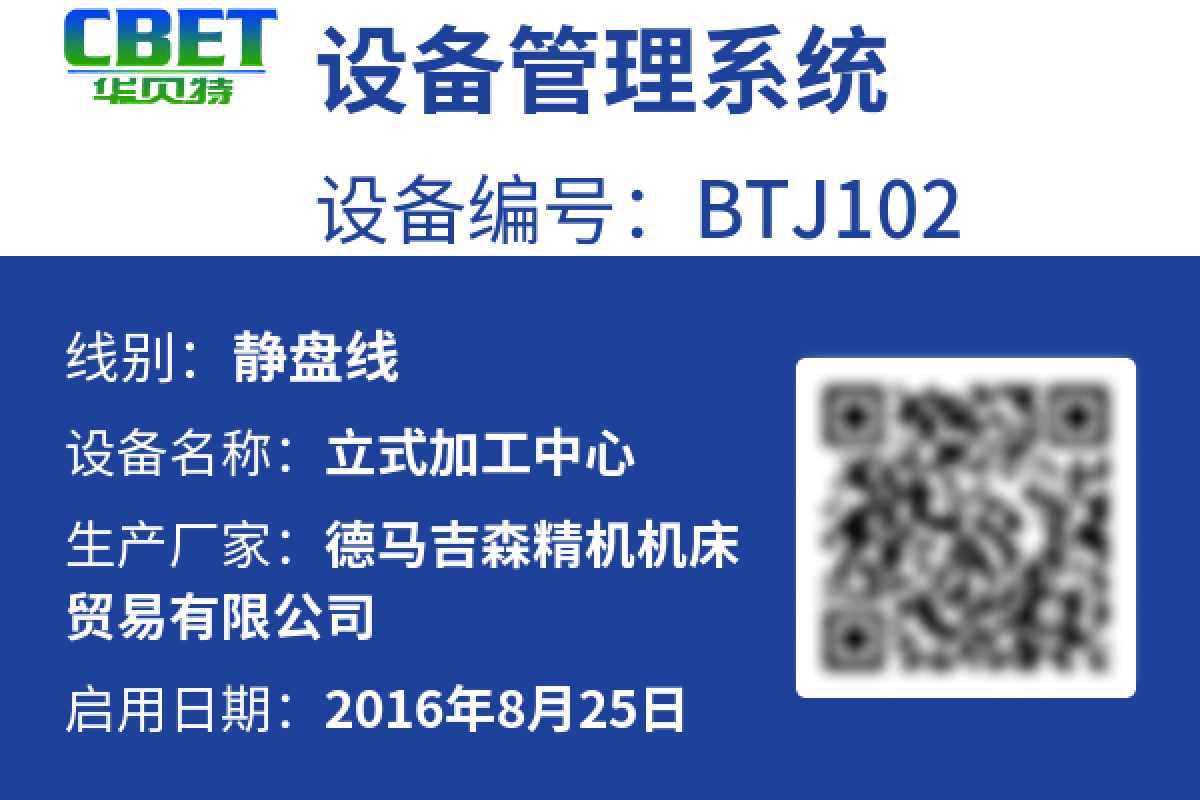

Based on the equipment list, QR codes were generated in bulk, implementing a one-code-per-machine system. These QR codes were then affixed to the equipment for quick access to the system interface.

02 Inspection Innovation

Drawbacks of Traditional Paper-Based Inspection: The traditional paper-based method relied on checkmark confirmation, which could not guarantee the authenticity and completeness of the checks.

Digital Transformation:

On-site Photo Documentation: During inspections, key parameters are documented by taking geotagged photos on-site for upload, displaying the inspection time, thereby increasing transparency.

Information Push Notifications: After the inspection of critical equipment is completed, notifications are pushed to the WeChat Mini Program for interactive confirmation, ensuring the inspection's validity.

Inspection Reminder System: Inspection schedules are set up to automatically push inspection tasks, reducing omissions and improving the execution rate.

03 Maintenance Management

Challenges of Paper-Based Records: The previous paper-based recording method, involving checkmarks to confirm maintenance items, was prone to omissions and made it difficult to trace maintenance history.

Application of CaoLiao QR Codes:

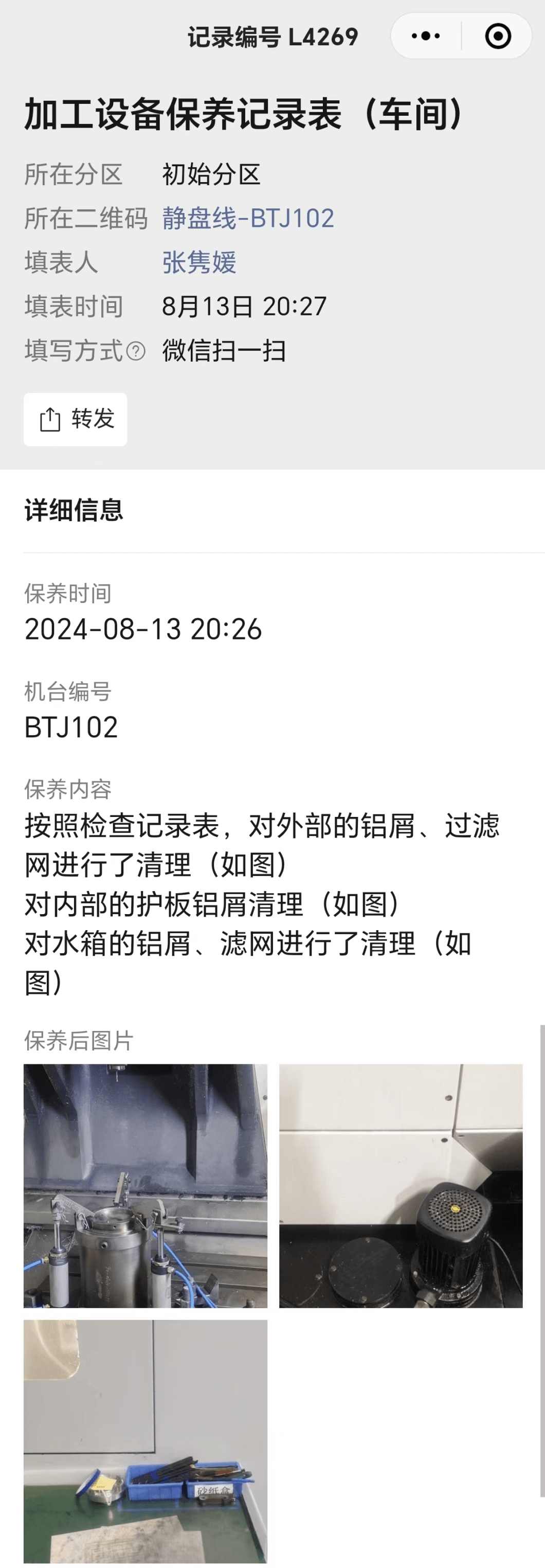

Display of Maintenance Plans and Standards on the QR Code: Based on equipment characteristics, standardized maintenance procedures are established and clearly displayed on the QR code.

Detailed Records: The condition before and after maintenance must be recorded by scanning the code and taking photos, ensuring every maintenance activity is traceable.

Message Push Notifications: Upon completion of each maintenance task, information from the process is automatically pushed to management personnel for online evaluation and interaction.

Refined Lubrication Management: Lubrication is a crucial aspect of equipment maintenance. By recording refueling operations, tracking is precise down to the amount of oil added, time, and even overall oil consumption. This ensures the effective operation of the equipment's lubrication system.

04 Closed-Loop Repair Management

Pain Points of Traditional Paper-Based Repair Request Management:

- Data Timeliness: In traditional repair request processes, slow information transfer often led to delayed repair responses.

- Accuracy: Manually filled request forms were prone to errors, affecting the accuracy of subsequent repair decisions.

- Unknown Repair Effectiveness: After repair completion, there was a lack of effective mechanisms to verify the repair outcome, making it difficult to assess repair quality.

- WeChat Group Reporting: Our company initially attempted to collect repair data through WeChat groups. While this improved immediacy to some extent, it still faced challenges: inconvenient historical fault tracing. Although it facilitated instant communication, fault records were scattered, hindering long-term management and analysis.

CaoLiao QR Codes: Comprehensive Optimization of the Repair Process

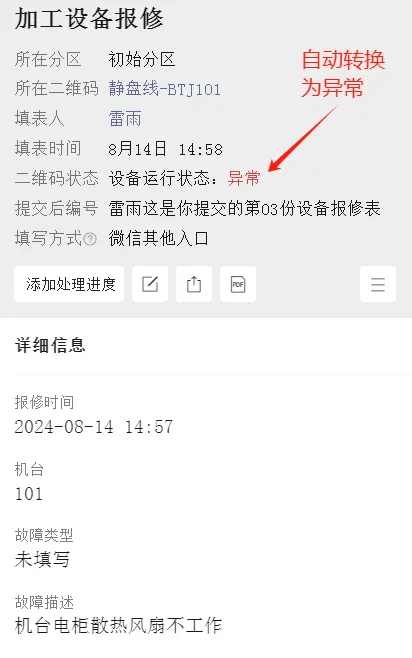

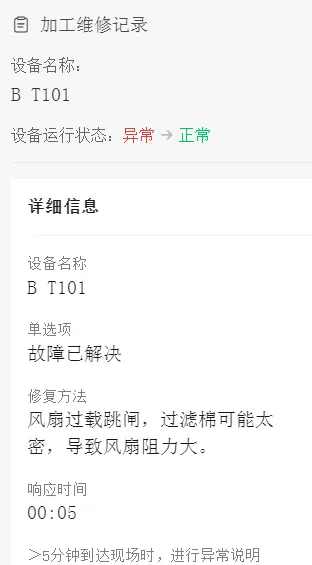

Scan to Report Repair: Each piece of equipment is equipped with a dedicated QR code. Employees can quickly submit repair requests simply by scanning the code, and the equipment's QR code status switches to 'abnormal'. This greatly enhances the convenience and timeliness of data submission.

After submitting a repair request, the QR code status automatically switches to abnormal and pushes the notification to the equipment engineer.

Standardized Repair Reporting: The maintenance team scans the QR code to record the repair process and results. Using a standard format ensures information accuracy and standardization.

When the submission indicates the fault is resolved, the equipment's operational status automatically switches back to normal.

WeChat Push Notifications: When the repair status changes, automatic notifications are pushed to relevant personnel, ensuring information transparency.

Full Lifecycle Management: From inspection and maintenance to repair history records, CaoLiao QR Codes enable digital management of the entire equipment maintenance lifecycle.

05 Data Dashboard: Decision Support

Equipment Operation Data Overview: Clicking on the status dashboard displays real-time equipment operational status, making abnormal situations and repair progress clear at a glance.

Maintenance Reminders and Overdue Alerts: The system proactively issues reminders for repair and maintenance tasks that are approaching their due date or are already overdue, ensuring equipment remains in good operational condition.

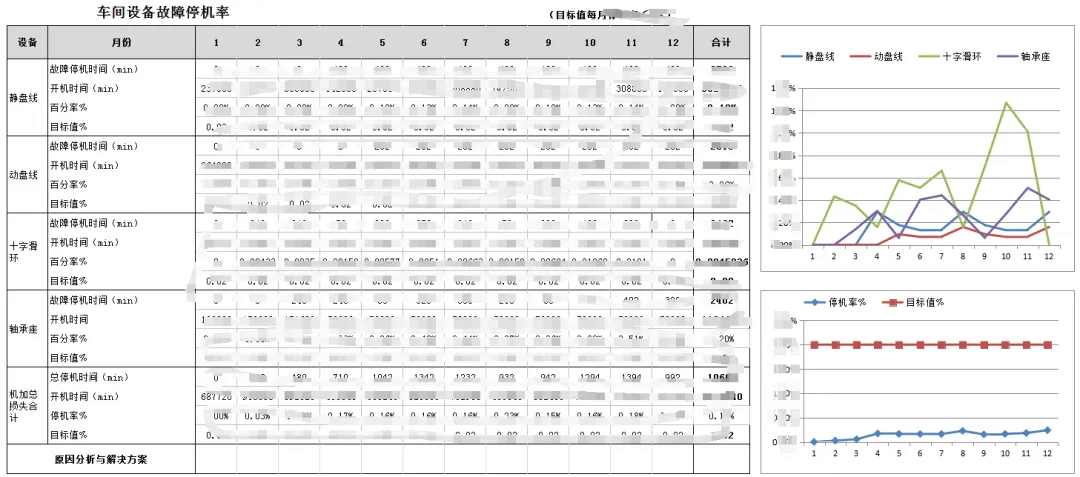

Backend Data Export for Analysis: Data can be exported for sorting and analysis, generating equipment utilization rate reports. CaoLiao QR Code backend data.

Equipment Utilization Rate Report: After exporting the data and importing it into a pre-set format, fault reports are generated directly.

Continuous Improvement: Based on dimensions such as mean time between failures (MTBF), failure frequency, and downtime, issues are identified and incorporated into the corresponding machine's QR code for ongoing improvement.

06 Summary

In summary, leveraging its unique and convenient technological advantages, CaoLiao QR Codes have been deeply integrated into Better's equipment management system. They have not only streamlined the repair request process and enhanced the efficiency and quality of maintenance work but also, through the data dashboard, provided management with a basis for scientific decision-making. This has helped Better New Energy Technology Co., Ltd. ascend to a new level of intelligence in the field of equipment management.