Electrical Cabinet Inspection

Inspectors scan QR codes to record checkup status. Managers can preset inspection items to standardize electrical cabinet inspections.

Configure notifications to receive immediate alerts via WeChat for abnormal inspection results.

Basic Information

- Monthly installations: 48,149

- Monthly visits: 70,238

- Original article: https://cli.im/template/detail/2684358

Case Tag Images

Usage Guide

1. Problems Addressed

Traditional electrical cabinet inspections face these issues:

- Manual records are error-prone and potentially falsified

- Abnormal conditions cannot be promptly addressed

- Paper-based data is difficult to aggregate

Solution: Replace paper checklists with dynamic QR codes (one QR code per device).

- Inspectors scan via WeChat to view device info, perform itemized checks with on-site photos to prevent errors/fraud.

- Automatic alerts notify maintenance staff of abnormal results for immediate action.

- All data is stored in accounts for real-time tracking, traceability, and exportable analysis.

Suitable for distribution cabinets at construction sites, factories, residential complexes, etc.

Note: For large-scale deployments, use bulk QR codes generation for centralized management. Learn more

2. Device Profiles via QR Code

One QR code per device provides:

- Device parameters and documentation

- Real-time status updates

- Inspection form access

- Historical inspection records

Tip: Add multiple forms (e.g., troubleshooting logs, equipment activation records) to a single QR code.

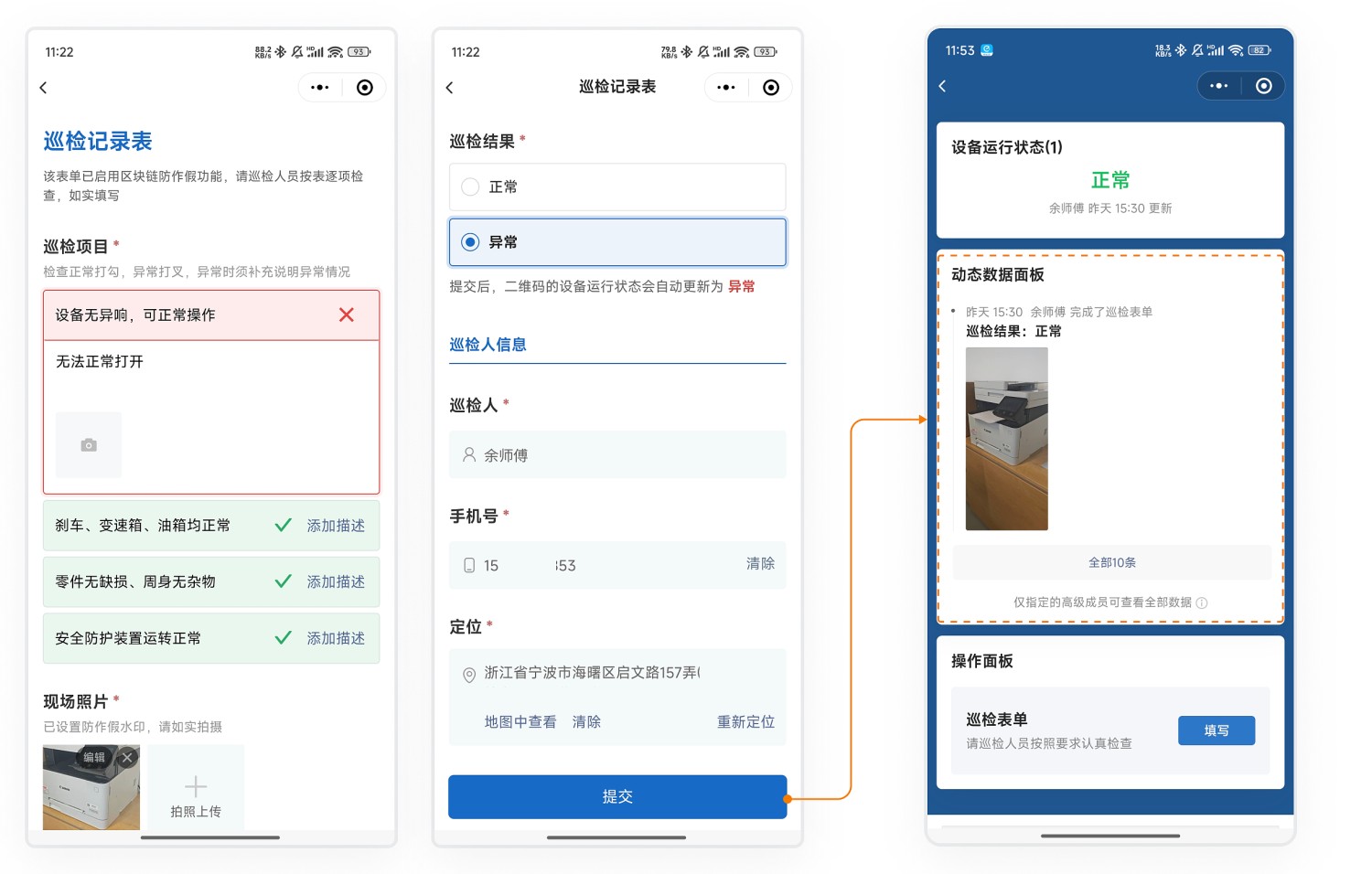

3. WeChat-Based Inspection Recording

Enforce authenticity with:

- Mandatory on-site photo capture

- Auto-timestamped/geotagged photos

- Blockchain notarization for data integrity

Collected data is displayed on the dynamic data panel. View form features

4. Abnormal Condition Handling

Automated WeChat alerts trigger:

- Maintenance staff to document repairs

- Inspectors to verify resolution

Full process logging enables post-analysis. Scenario details

5. Scheduled Inspections with Reminders

Configure maintenance plans (e.g., monthly):

- Inspectors view schedules via QR code scans

- Managers monitor compliance via mobile dashboards

- Pre-expiration alerts via WeChat

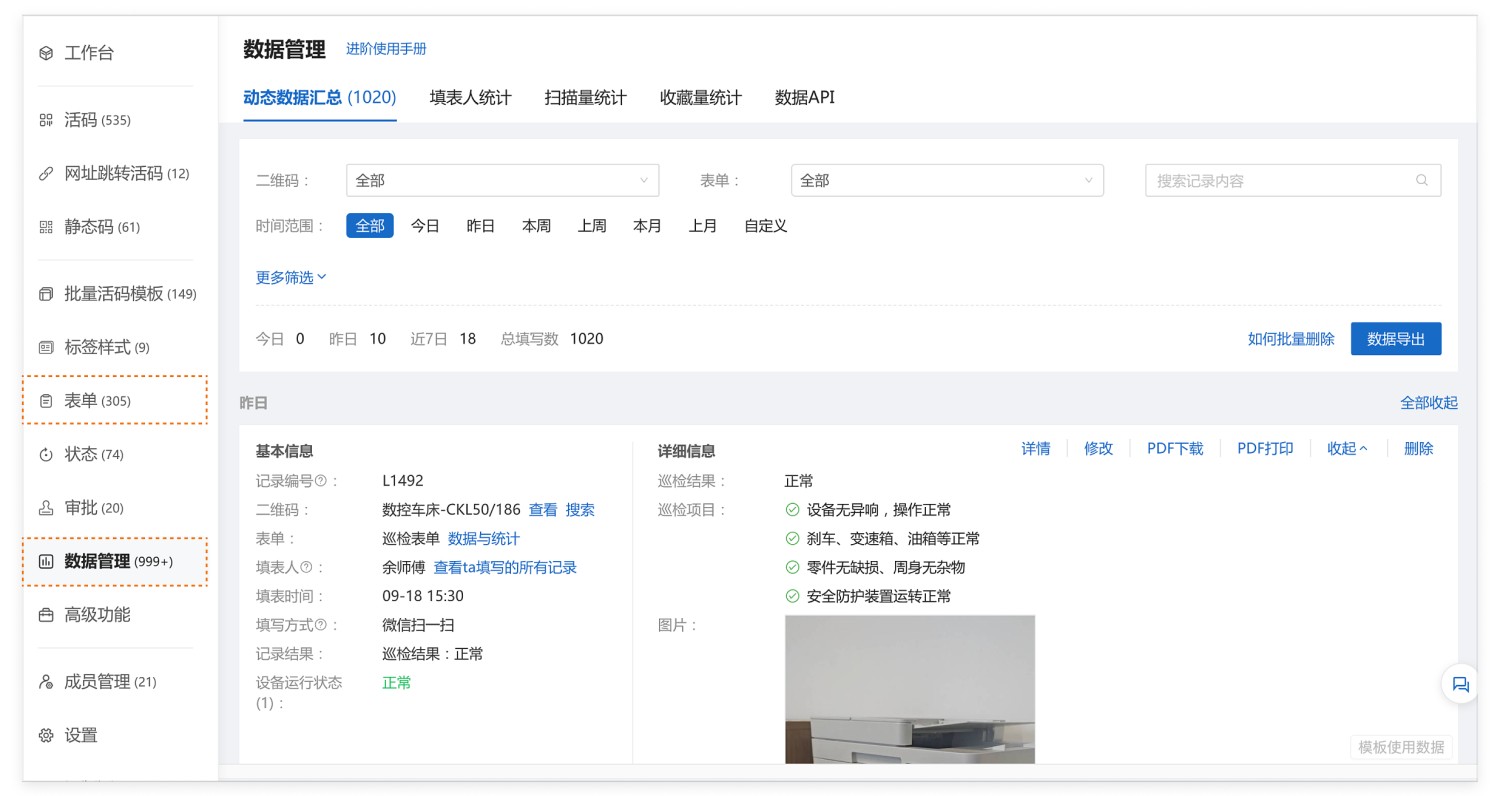

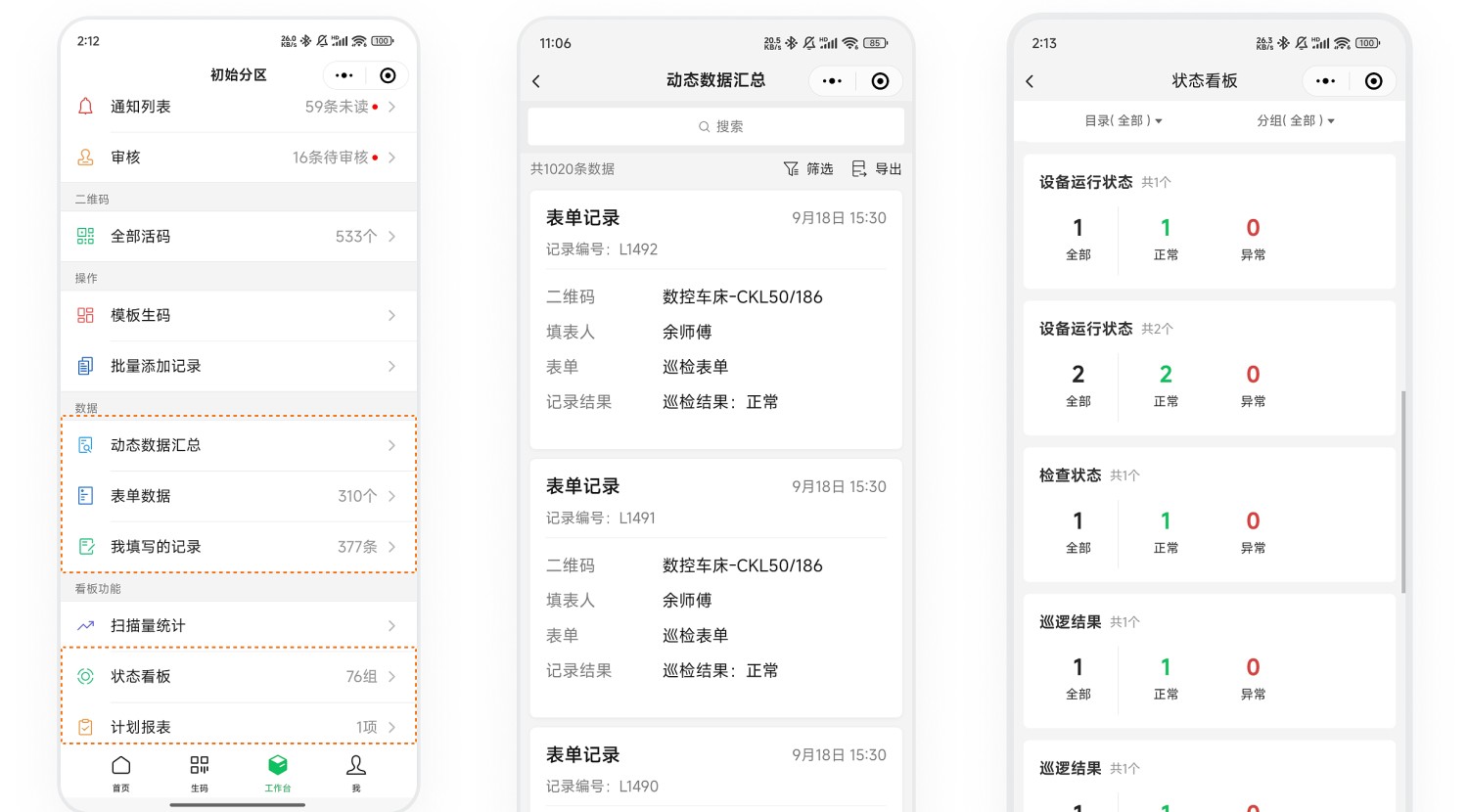

6. Data Management

6.1 Data Access

All submissions are stored in your account. Access via:

Desktop workbench

Mobile WeChat Mini Program workbench

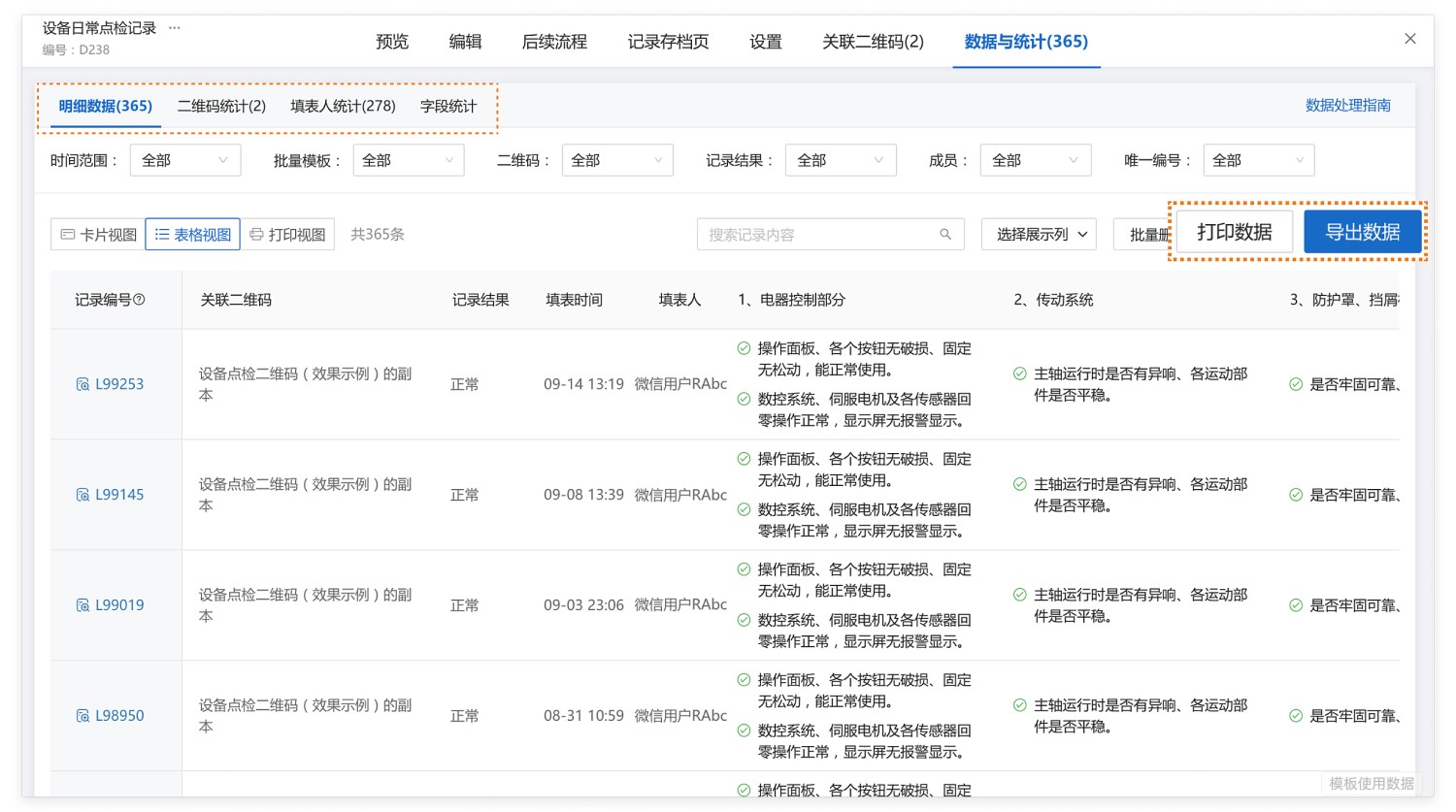

6.2 Data Export & Analytics

Export to Excel/PDF for:

- Local processing and reporting

- Printable summaries

6.3 Data API Integration

Enable:

- Real-time alerts to WeCom/DingTalk/Lark groups

- Custom dashboards via visualization tools

7. FAQs

7.1 Permissions Configuration

Control access to:

- QR code viewing

- Device status changes

- Form submissions

- Data visibility

7.2 Managing Multiple Device Types

Solutions:

- Advanced members (paid plans): Grant management permissions. Learn more

- Partition management: Separate devices/data by zones. Tutorial

7.3 Monitoring All Device Statuses

QR codes auto-update device statuses (e.g., "Normal" → "Abnormal"). View real-time status distributions via dashboards. Details

7.4 Full Implementation Guide

Available: Step-by-step tutorial

Client Cases

- China Construction Shenzhen Decoration: "One Machine, One File" Safety Management

- Zhongyifeng Xingmei Road Project: QR Code Applications in Construction Safety

- China Energy Engineering Guangdong Thermal Power: Equipment & Fire Safety Inspections

- Zhongyifeng Construction Group: Digitalized Electrical Cabinet Management

- China Energy Construction Anhui Electric Power: QR Codes in Team & Equipment Management

- Hunan Transportation International: QR Codes in Engineering Material Management

- Nantong No.2 Construction Group: On-site Informatization Tools

- CCCC Second Highway: Controlled Inspection Workflows

- China Railway 17th Bureau: Precision Management Era

- China Construction Third Bureau: Site Management Solutions

- China Construction Second Bureau: Construction Project Applications