Inspection QR Codes + Monitoring Dashboards: Building an Intelligent Production Management System

Original: https://cli.im/article/detail/2329

The No. 8 Oil Production Management District actively implements Sinopec's "4556" key tasks, striving to enhance innovation and efficiency, accelerate the pace of intelligent transformation, and deeply integrate production with smart technologies. It has innovatively introduced the "Equipment QR Code + Mixed Transmission Pressure Monitoring Dashboard" model, constructing a comprehensive intelligent management system that makes the production process more transparent, efficient, and safe.

Intelligent Equipment Inspection: Innovative Management Enhances Quality and Efficiency

Sinopec Shengli Oilfield Linpan Oil Production Plant has innovatively implemented an equipment QR code management model, using CaoLiao QR Codes to build an equipment inspection system. Dedicated QR codes are affixed to equipment and facilities, allowing frontline staff to scan the code during inspections to immediately access and fill out equipment inspection and maintenance records, viewable via WeChat scan. Equipment managers in the management district can monitor equipment usage and frontline inspection execution through the backend workbench. All information is automatically uploaded after being recorded on-site via the equipment inspection management system, making inspection data richer, more standardized, and easier to summarize, review, and trace.

This one-code-per-item equipment management approach addresses the drawbacks of traditional manual recording methods, such as non-standardized equipment check-in data and poor timeliness, ensuring more thorough equipment inspections and more accurate data.

Intelligent Mixed Transmission Monitoring: Ensuring Safe Production

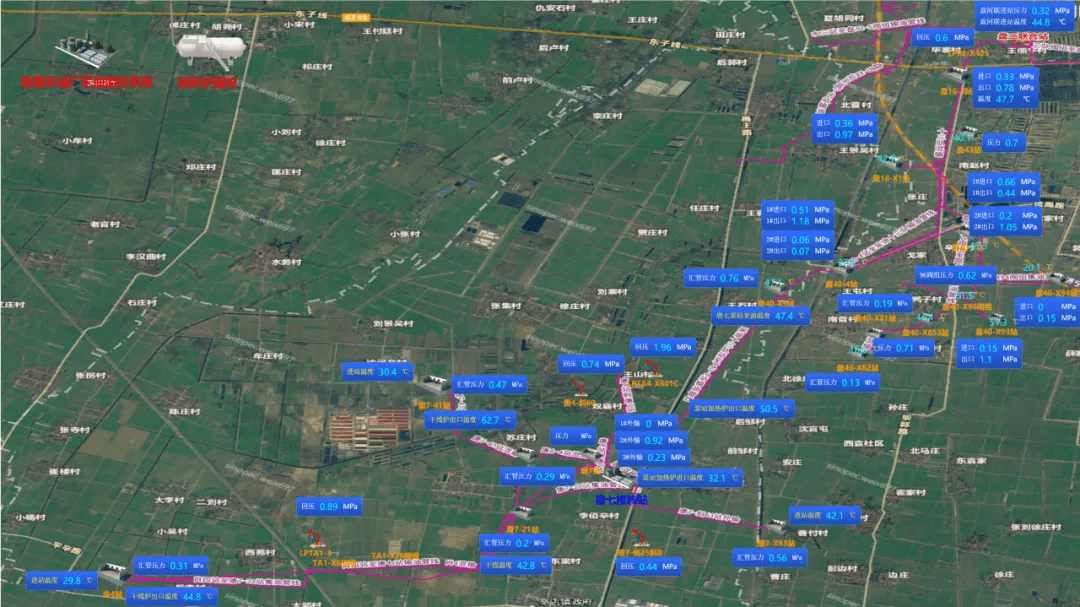

The implementation of the mixed transmission pressure monitoring dashboard drives production management upgrades. This dashboard provides an at-a-glance view of real-time data for mixed transmission mainline pressure, temperature, and branch line metering. Injection-Production Control personnel can clearly observe value fluctuations and trends, facilitating close tracking of data changes and making production dynamics clearly visible.

Based on data prompts, various Injection-Production Stations respond promptly to production needs, adjust production parameters, and optimize operational measures, forming an efficient work network. Once production data exceeds normal ranges, the dashboard precisely locates the abnormal area. This information is quickly captured by Injection-Production Control personnel, enabling the rapid development of reasonable emergency response plans and immediate communication to the production frontline. This prevents production hazards caused by information delays, ensuring production stability and continuity.

The intelligent production management practices of the No. 8 Oil Production Management District have not only effectively improved the efficiency of production dynamic reporting and emergency response but have also significantly reduced safety production risks. The next step involves continuing to intensify the application of intelligent technologies, constantly exploring new methods and approaches to add new impetus to crude oil production and inject more intelligent power into the high-quality development of the oil production plant.

Original article reprinted from the WeChat Public Platform: Sinopec Shengli Oilfield Linpan Oil Production Plant [《Speed and Efficiency Boost丨"Code"-Based Inspection + Monitoring Dashboard, Empowering Production Management Upgrade》](https://mp.weixin.qq.com/s/MQ65-0X2qMML1luctNtN3Q "《Speed and Efficiency Boost丨"Code"-Based Inspection + Monitoring Dashboard, Empowering Production Management Upgrade》")