Always Missing Equipment Inspection Records? We Solved It Completely With This Method!

Original: https://cli.im/article/detail/2361

In the manufacturing industry, equipment inspection is an unavoidable part of operations. Especially for production lines that require continuous operation, even a loose screw or an abnormal motor temperature can lead to downtime or even safety risks. However, precisely because inspections are routine and repetitive, many companies face a very practical problem—inspection records are always missing.

Our factory used to have this issue too. We had established inspection protocols, and inspectors were making their rounds daily, but when it came time to compile records at the end of the month, we'd find forms either unfilled or filled with illegible handwriting and incorrect timestamps. Even worse, sometimes when a malfunction occurred and we needed to trace back the records, we'd discover that the inspection data for a certain period was simply missing.

This problem isn't new; after asking several peers in the industry, we found it's a common phenomenon. Everyone understands: relying on human memory and self-discipline in processes is bound to lead to oversights eventually.

We tried various methods. Initially, we strengthened management, requiring team leaders to supervise daily, sign off, and clock in. But honestly, that was just treating the symptoms, not the root cause. The "person supervising person" approach might work for the first week or two, but over time, things reverted to the old ways.

Later, we tried using a system. Our factory had previously purchased a management system, and we embedded an inspection module into it. It seemed feature-rich on paper. But the frontline inspection staff simply didn't want to use it—the process was too complicated, and they had to go to the office and use a computer to fill in the records. Not to mention, whenever there was an issue and we needed to modify form fields, we had to wait for the IT department. Each modification took a couple of days, and by the time old requests were handled, new ones piled up. Chasing the IT team became a waiting game.

The turning point came during a study tour. While visiting a factory in another region, we noticed a QR code posted next to each piece of equipment. Out of curiosity, we asked and learned it was their "equipment electronic file"—scanning the code allowed them to fill in the day's inspection records on the spot. Their engineer mentioned that they too had faced issues with missing and falsified data before. After implementing QR codes, not only were records filled completely, but they could also check records in real-time, automatically archive them, and significantly improve inspection efficiency.

This inspired us. Back at our factory, we started researching similar solutions and eventually chose to use the "CaoLiao QR Code" platform to build ours. The reason was simple: it required no development and was easy to operate, making it particularly suitable for small factories like ours without a dedicated IT team.

We started by generating unique QR codes for all critical equipment using CaoLiao QR Code. Their platform offers many templates, and all content within these templates can be customized according to our factory's needs—items like temperature, current, abnormality status, remarks, and photo uploads could all be added. There's even an AI feature that allows you to take a photo of our old paper-based records, upload it, and automatically generate an inspection form. We had QR codes generated in no time.

During the initial testing phase, I simply printed the generated QR codes using the office printer, taped them onto the equipment with clear tape, and they were ready for use. Once the QR codes were in place, inspectors only needed to scan them with their WeChat app daily to fill in the records. The system automatically logs the inspection time, personnel, and whether any faults were detected.

Even more practical is CaoLiao QR Code's support for missed inspection reminders. We set up daily inspection schedules, and the system automatically reminds the responsible personnel to fill in records before their shift starts. If someone forgets, the backend automatically shows "Overdue - Not Completed," allowing managers to instantly see which equipment hasn't been inspected on time. No more sifting through records after the fact to find out which machines were missed.

Another feature I really appreciate is the inspection anti-fraud capability. With the old paper-based method, employees might backfill records right before checks, or even mark 'normal' when there were actual issues, leading to equipment downtime later. Now, with the CaoLiao QR Code equipment inspection management system, we can restrict record submission to the physical location of the equipment. Combined with anti-counterfeit watermarks and requiring on-site photos, it effectively ensures that employees actually go to the site and perform the inspection. Plus, with blockchain notarization, inspection data can be stored on the blockchain, serving as potential legal evidence if issues need tracing later.

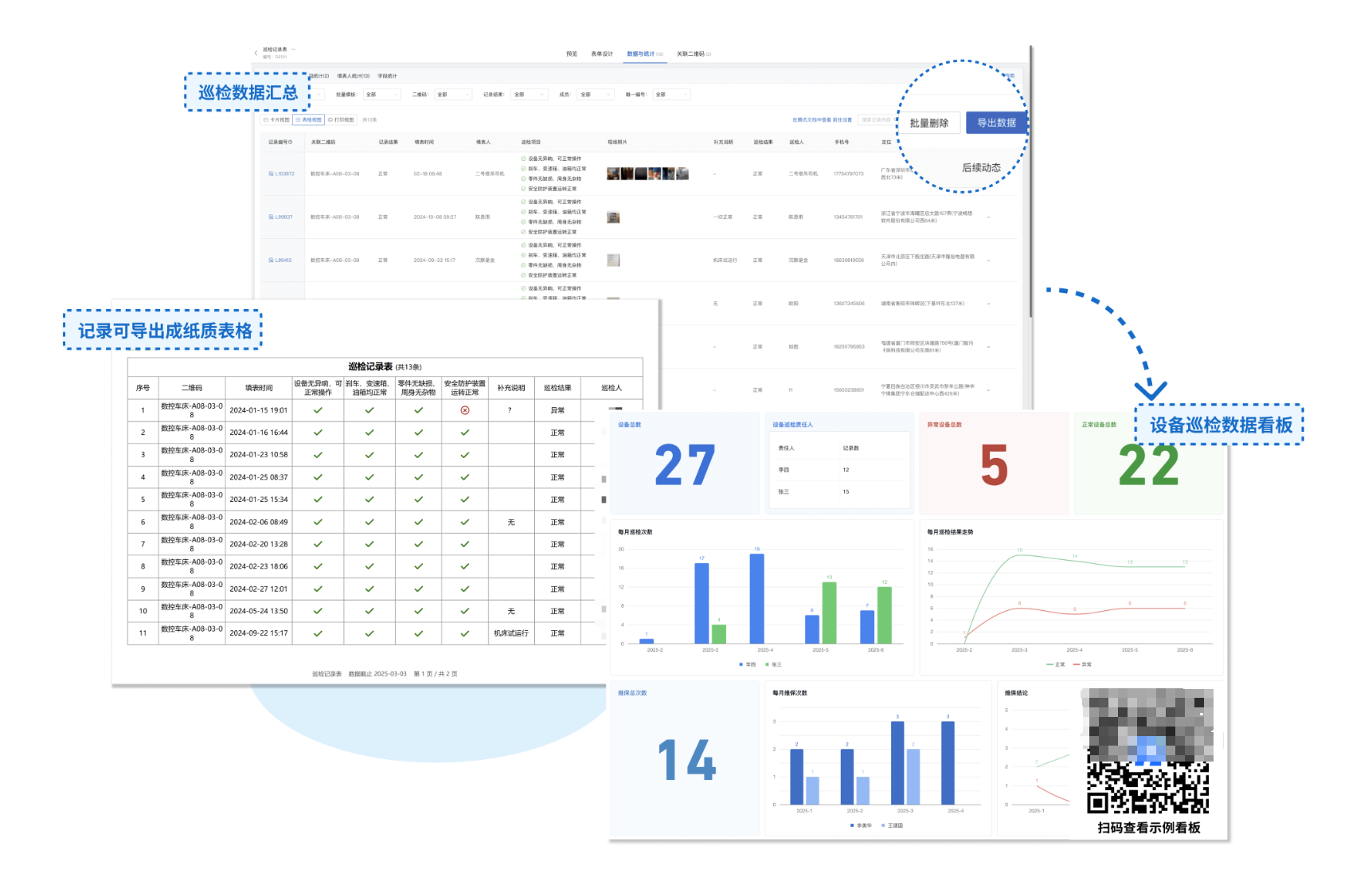

The data aspect is also very clear. All inspection data is automatically archived in the backend, filterable by equipment, time, or personnel. Reports can be directly exported for archiving, and we can even use CaoLiao's API feature to create data dashboards. If an unexpected situation arises and we need to review records, we can trace the source in just seconds.

After using it for over two months, the most direct feeling in our equipment department is: inspections have become standardized, and management is much easier. Before, confirming "Did you fill it out?" relied on constant questioning; now, "I can see everything clearly in the backend." Previously, we had to manually compile dozens of paper forms at month-end; now, we can export reports with one click. Especially when problems occur, records can be pulled up immediately, making responsibility tracing much clearer.

Ultimately, our success wasn't due to high technical barriers; it was about choosing the right tool and streamlining the process. Platforms like CaoLiao QR Code are designed for lightweight digital management. They don't require system integration or outsourced development. Essentially, one person in our office can set it up and modify it. Want to add a new field or adjust the logic? Change it in the backend, and it takes effect immediately. It's really well-suited for workshops like ours with limited management staff and flexible needs.

We are now planning to apply this model to other scenarios like equipment maintenance, spare parts management, employee safety training, and security guard check-ins—using WeChat scanning to handle daily tasks, linking all frontline workflows together. This doesn't add burden to employees and enhances data integrity.

Many friends ask me if it's worth implementing. My answer is: if you're also struggling with incomplete inspection records, severe underreporting, and unrecoverable data, then you might want to try a "light transformation" using a tool like CaoLiao QR Code. It's not complicated, it's affordable (or even completely free for basic requirements), and it doesn't require major overhauls. You can set it up simply and solve the problem.

If you're interested in trying it out, you could start with one or two pieces of equipment on a small scale. If the results are evident, then gradually expand. We started with a pilot on a few key devices, and within days, everyone was using it smoothly.