Luoyang Molybdenum Group: Management Innovation in Equipment Spot Inspection Using QR Codes

Original: https://cli.im/article/detail/2426

Tungsten Industry Company No. 1 uses QR codes for online spot inspections to promptly monitor equipment operating status. In the first half of the year, the equipment operation rate reached 98.7%, laying a foundation for exceeding production targets.

Upon entering the production workshop of Tungsten Industry Company No. 1, our reporter noticed new labels on the equipment. "By scanning with WeChat on our mobile phones, we can see inspection options such as equipment name, main motor electronic temperature, main motor bearing oil temperature, fixed-end high pressure, fixed-end bearing temperature, and abnormal conditions. After inspection, we must take photos and upload them, allowing workshop supervisors and company leaders to monitor the equipment's operational status," explained a technician conducting equipment inspection. "Since implementing these QR codes, we dare not be negligent during inspections. This approach genuinely benefits equipment maintenance, as potential faults are eliminated in their early stages."

Operation Interface After Scanning the Equipment QR Code

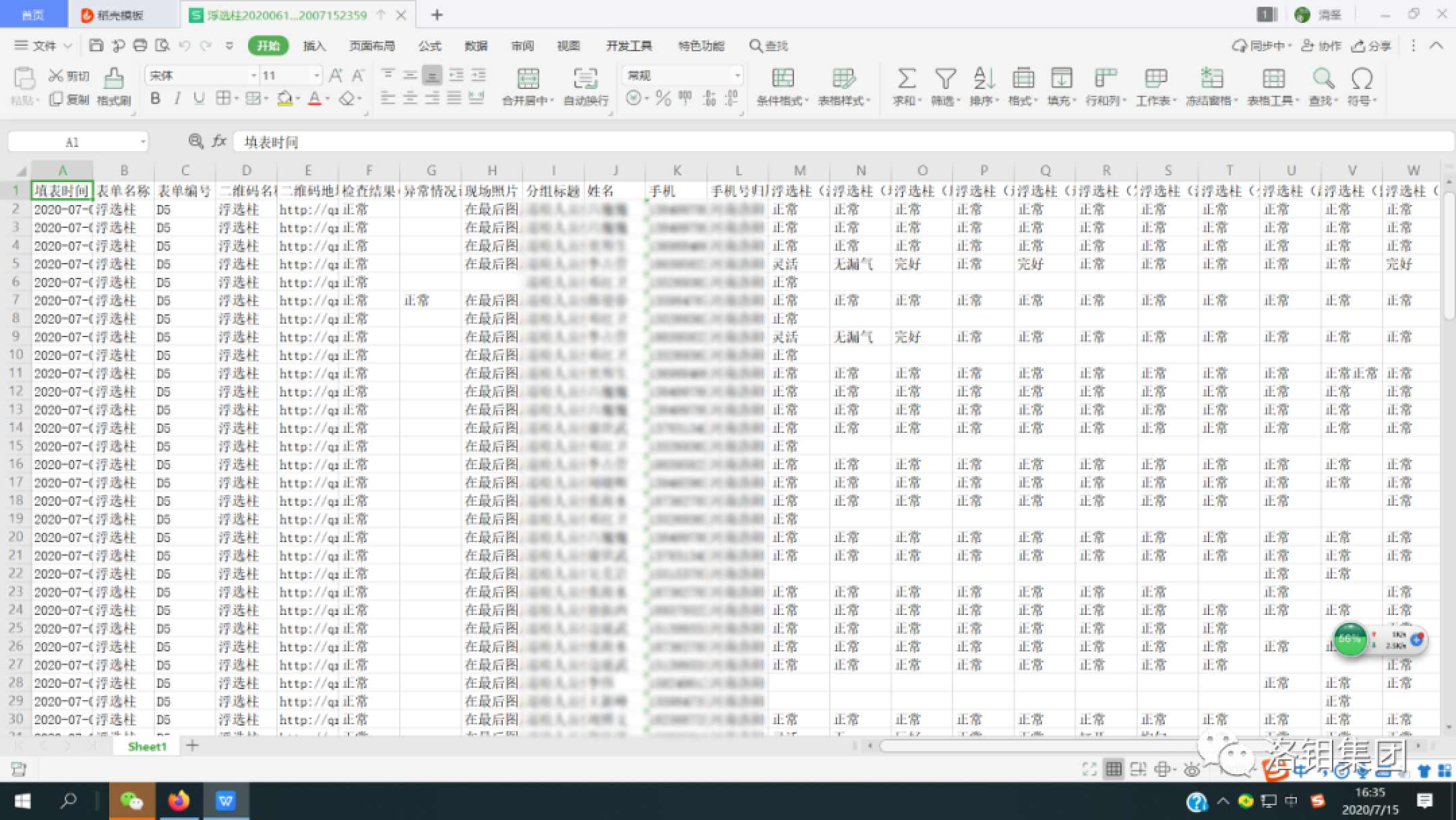

Online Tracking Overview of Equipment Spot Inspections

"For managers, the most crucial task is to create an open environment that stimulates employees' innovative enthusiasm. How can we ensure timely and high-quality daily inspections? Through collective brainstorming, we achieved the current results," stated Wang Yanwen, Manager of Tungsten Industry Company No. 1.

Personnel from production, safety, and environmental departments, workshop supervisors, and technical experts joined this innovation initiative. Using popular survey systems as a starting point, they consulted and experimented to embed various equipment parameters into daily inspection form QR codes. Additional features like on-site audio recording, photos, and location tracking were integrated, enabling real-time inspection monitoring and control. This facilitates prompt awareness of equipment status and prevents production disruptions due to equipment failures. Beyond inspection QR codes, Tungsten Industry Company No. 1 also leverages information technology to enhance equipment responsibility mechanisms, strengthening equipment management and significantly reducing component consumption costs.

Furthermore, the company intensified performance management by breaking down production technical indicators, key materials, electricity, natural gas, and other assessment metrics. These are allocated to teams and individuals, using performance evaluations to differentiate salaries and establish a competitive "horse race" mechanism. This not only boosts employees' learning awareness and cost-saving mentality but also fully mobilizes initiative, promoting the achievement of production targets.

"Since implementing the new performance system, salary differences exist for similar roles across different shifts or positions within the same shift. This fosters healthy 'competition' among employees, encouraging teamwork and active innovation," Manager Wang Yanwen remarked.

Reprinted from WeChat Public Platform: Luoyang Molybdenum Group CMOC

Read the full article: Management Innovation Exchange Part 1: Tungsten Industry Company No. 1's Effective Equipment Inspection "QR Codes"