Why Use QR Codes for Equipment Inspection?

Original: https://cli.im/article/detail/2373

If you are a head of equipment management, you've likely encountered issues like missed inspections, falsified checks, or lost data in your daily work. If your company still relies on traditional paper-based inspections and you need to compile and report data, facing stacks of paper inspection forms with messy handwriting and blurred information makes tracing records like finding a needle in a haystack. Once problems occur, subordinates might shift blame, leaving no way to verify the facts.

Faced with these challenges, perhaps it's time to try a simpler, more reliable method: using QR codes for equipment inspection. It doesn't require expensive, complex systems or platforms that need IT engineers to set up. With CaoLiao QR Code, every equipment manager can build a complete equipment management system themselves.

Just a mobile phone, a QR code, and a WeChat scan—inspections can run smoothly.

1. Why Use QR Codes for Equipment Inspection?

The biggest issue with traditional inspections is the inability to digitize data, and the information chain breaks too easily.

Lost paper forms, data entry errors, inspection tasks with no follow-up... each step hides potential risks. Using QR codes to link everything together is like giving each piece of equipment its own "archive room." Just scan the code, and all inspection records, photos, and historical maintenance details become clear at a glance.

Most importantly, everyone uses WeChat to scan and fill out forms—no training needed, no extra apps to download—making implementation exceptionally easy.

2. The Changes One QR Code Brings

1. Faster and Smoother Inspection Processes

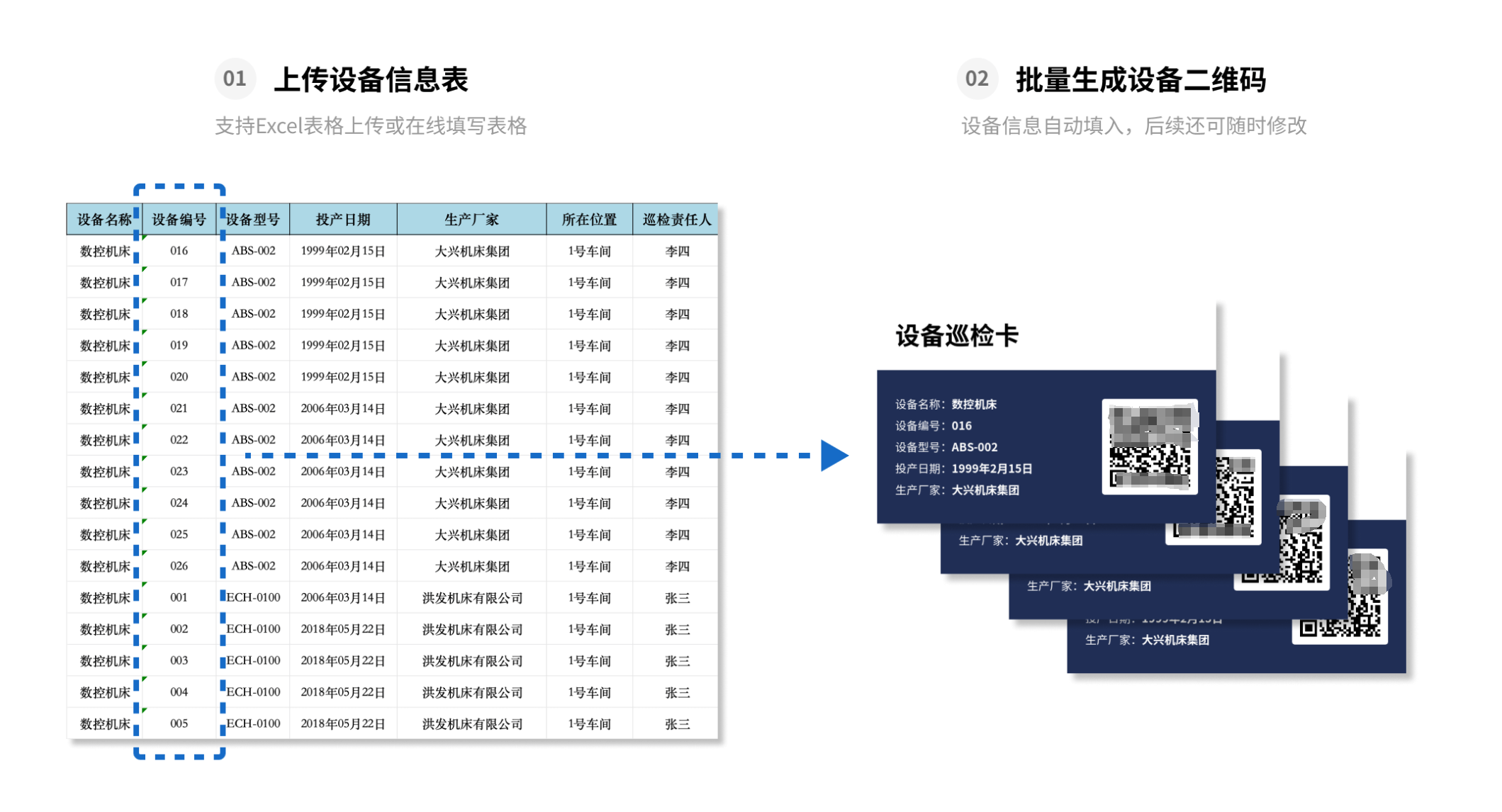

The CaoLiao QR Code platform supports bulk QR codes generation for equipment. You just need to organize your equipment list into a spreadsheet, upload it with one click, and generate hundreds or thousands of QR codes simultaneously—one QR code per device. This eliminates the hassle of manual entry one by one, making it especially suitable for scenarios with large numbers of devices. Furthermore, there are many mature templates available for QR code label styles—no need to design them yourself; just download and print.

During on-site inspections, open WeChat, scan the code, and fill out the inspection form—covering check items, photo uploads, anomaly notes, etc. Frontline personnel can complete an equipment inspection in just a few minutes with simple steps.

2. No More Missed or Falsified Inspections

A major concern for many companies implementing electronic inspections is: Did the person actually show up? Was the on-site check performed? Is the data real?

CaoLiao QR Code reduces opportunities for falsification at the source through features like photo watermarks and restrictions that require forms to be filled out only in specified areas. Photos taken automatically include time and location information, and the system can be set to "only allow on-site photos, no gallery uploads," ensuring every inspection record is authentic and reliable. Additionally, inspection schedules can be set in advance, with automatic reminders sent to responsible persons before deadlines. Even if inspectors forget, the system won't.

3. Timely Fault Handling, Forming a Management Loop

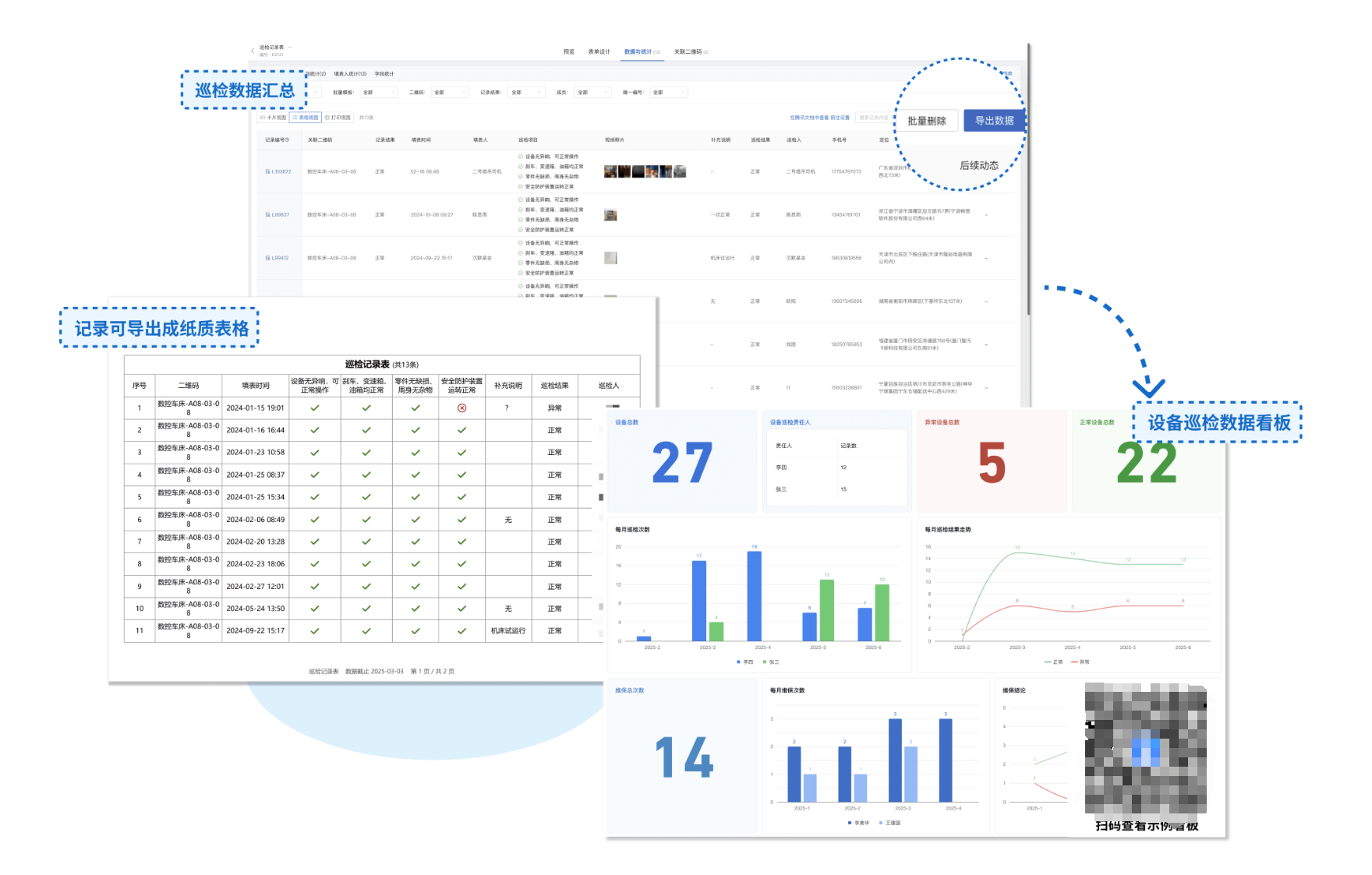

When an anomaly is detected during an inspection, simply reporting the issue via the scan automatically switches the equipment status to "abnormal" in the system and notifies the relevant responsible person in real-time. Subsequent personnel can handle repairs, acceptance checks, and close the fault report, with the entire process logged.

No need to make催促 calls or search through emails; the system's built-in message推送 significantly reduces response times.

4. Automatic Inspection Data Summarization, Easy Visualization

All inspection data is stored in the cloud and can be exported at any time by equipment, department, time period, etc. It supports one-click integration with Tencent Docs and Kingsoft Spreadsheets, or can be pushed via API to your own ERP or BI systems to generate charts and reports, enabling dynamic monitoring of equipment health.

Say goodbye to inefficient manual statistics and let data truly serve management.

5. Clear Responsibilities, Traceable Issues

With many devices and departments, unclear responsibilities easily lead to blame-shifting. CaoLiao QR Code allows for permissions management, assigning different responsible persons for different equipment or areas. Who manages which device, who is responsible for inspections and repairs—all are clearly recorded.

The workbench also maintains detailed operation logs, showing who created a QR code, who modified a form, etc., at a glance. When problems arise, there's no shirking or shifting blame—responsibility is traceable.

3. Free to Use, More Efficient with Paid Version

Many people ask: Do I have to pay to use it? No. The free version of CaoLiao QR Code can already cover the basic QR code inspection process. It includes unlimited devices, unlimited scan times, unlimited inspection records, permanently valid QR codes, and data that can be exported anytime.

If you need more efficient and flexible management—such as personnel role division, a more professional brand image, higher API data push quotas, or building an enterprise-exclusive WeChat Mini Program—you can upgrade to the paid version based on actual needs. Pay-as-you-go, costing less than 3000 RMB per year for robust usage.

4. Which Companies Use QR Codes for Equipment Inspection?

This solution is already very mature, inexpensive, and convenient, currently used by hundreds of thousands of large, medium, and small enterprises. Many well-known companies are also applying it:

- Bull Group: To address equipment management in their laboratories, they built an equipment monitoring and management system using CaoLiao QR Code, achieving results comparable to professional MES systems at a cost of less than 3000 RMB.

- COFCO Joy City: Purchased over 30 accounts at once, integrating QR codes into equipment inspections and safety patrols, making it part of COFCO Property's smart property system.

- China Molybdenum Co., Ltd.: Uses CaoLiao QR Code for online spot inspections, promptly grasping equipment operational status. Their equipment operation rate reached 98.7% in the first half of the year, laying the foundation for exceeding production targets.

These cases illustrate a fact: You don't necessarily need to spend a lot of money or implement large systems to achieve good digital management. Lightweight, practical tools are often more suitable for the real needs of the vast majority of enterprises.

5. Conclusion

Equipment inspection is, ultimately, a long-term, meticulous task that requires a sense of responsibility. A good tool can help us solidify that responsibility, smooth out the process, and safeguard the data. CaoLiao QR Code isn't a master key, but it can be a useful tool to make inspections simpler, more authentic, and more efficient.